Method of preparing main girder of wind turbine blade of wind driven generator set by using whole breath pultrusion plates

A technology of wind turbines and wind rotor blades, applied in applications, household appliances, household components, etc., can solve the problems of main girder products such as whitening, easy to wrinkle, and poor product quality, so as to achieve reasonable process design and avoid girder Wrinkle, operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

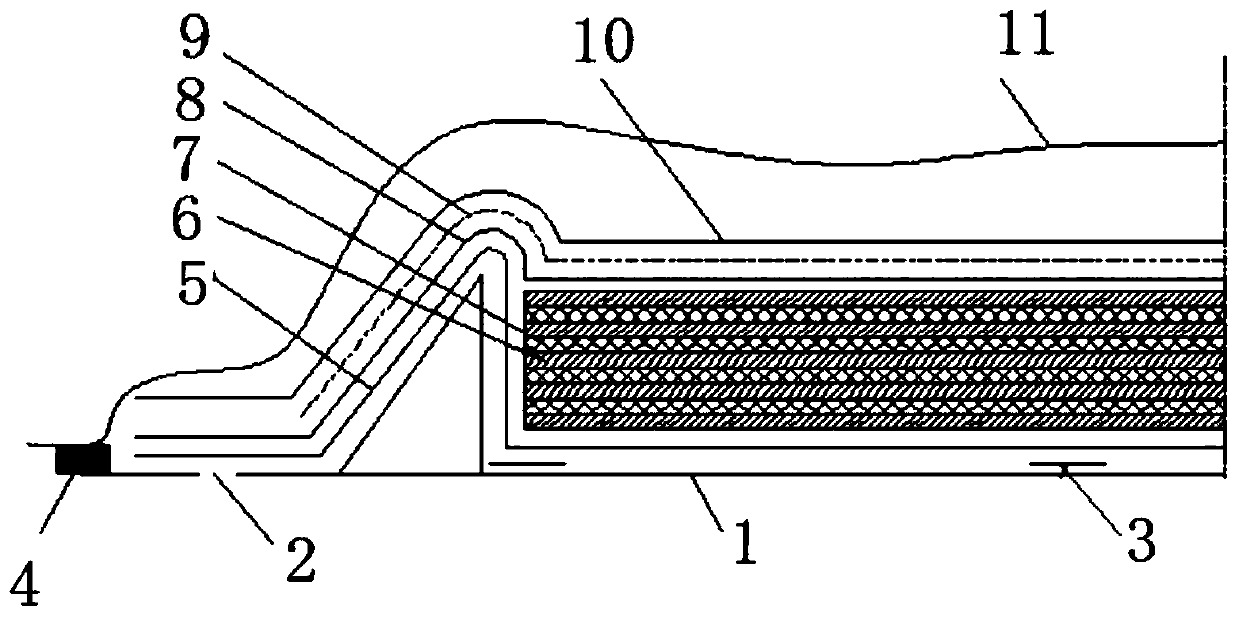

[0022] like figure 1 As shown, a method for preparing the main beam of a wind turbine blade with a full-width pultruded plate includes the following steps:

[0023] a. First, lay the first layer of release cloth 5 on the mold 1 by bonding the double-sided adhesive tape 3;

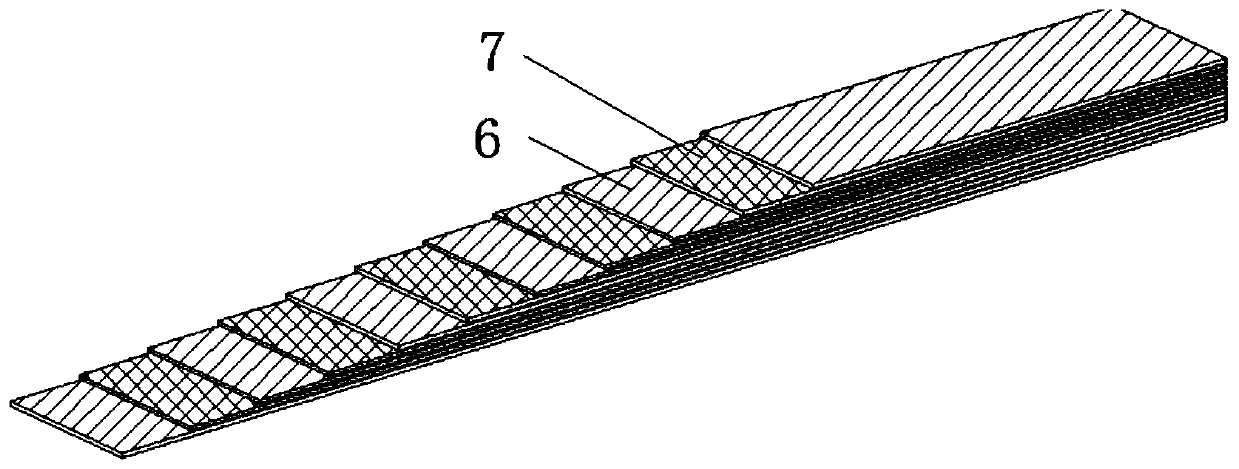

[0024] b. According to the design requirements, alternately lay the entire width of the pultruded board 6 and the resin film 7 on the first layer of release cloth 5;

[0025] c. Then lay the second layer of release cloth 8, perforated film 9 and air felt 10 on the uppermost full-width pultrusion board 6;

[0026] d. Then lay a vacuum film 11 on the air felt 10, seal the vacuum film 11 with a sealing tape 4, vacuumize to -0.098MPa through the suction port 2 on the mold, and heat to 80°C for curing and molding (structure such as figure 2 ).

[0027] A method for preparing the main beam of the wind turbine blade of a wind turbine with a full-width pultruded plate as described above, the full-width pultrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com