Super-limit tin alloy and preparation method thereof

A tin alloy, ultra-limit technology, applied in the direction of metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of easy deformation and failure of tin alloy weld materials, to avoid cracking or even falling off, eliminate residual stress, and better The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following is further described in detail through specific implementation methods:

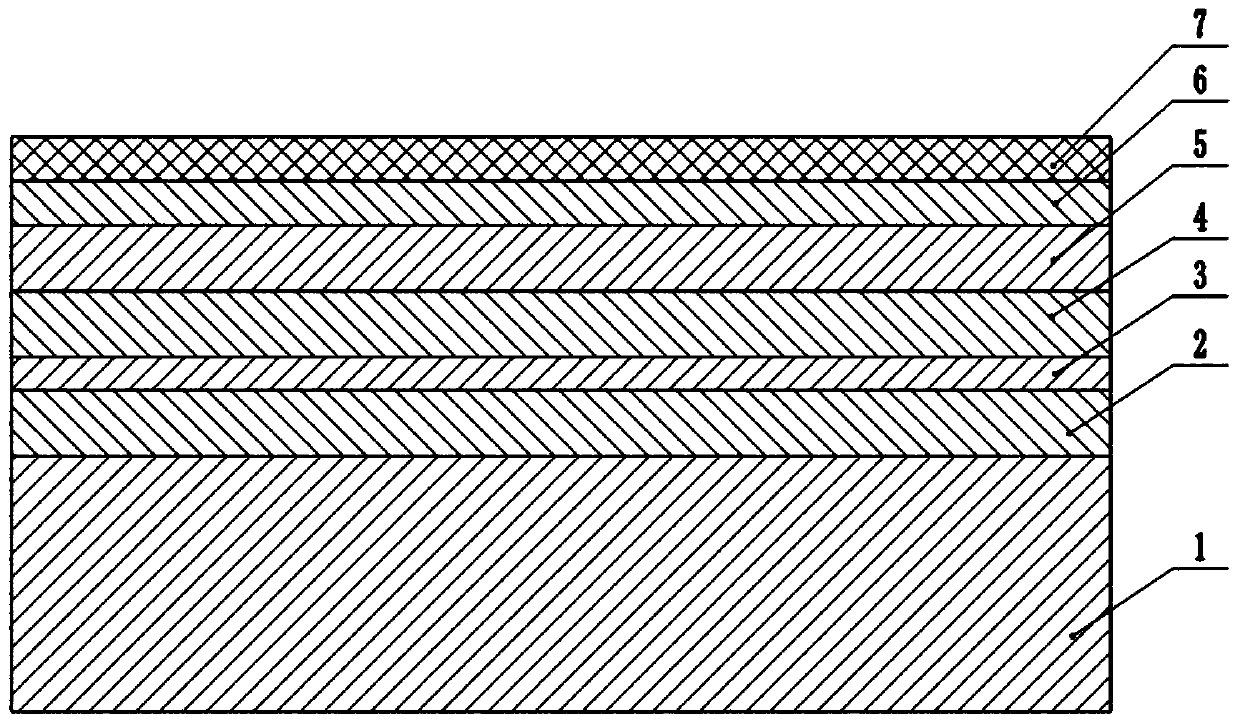

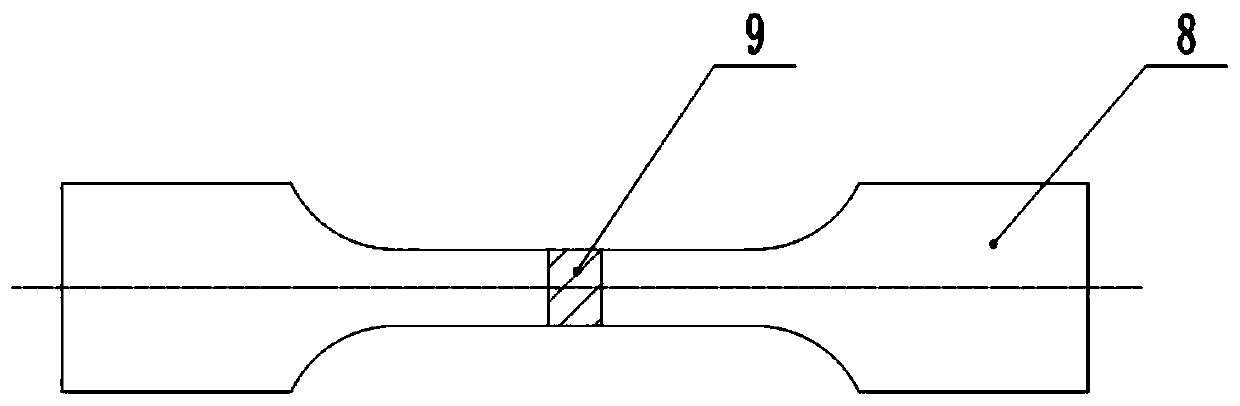

[0046] The reference signs in the drawings of the description include: tin alloy substrate 1, bonding layer 2, ceramic layer 3, sealing coating 4, reflective layer 5, catadioptric layer 6, insulating layer 7, welding base material 8, weld seam 9.

[0047] The present invention provides an ultra-limit tin alloy, such as figure 1 As shown, including a tin alloy substrate 1, the surface of the tin alloy substrate 1 is sequentially deposited with a bonding layer 2 with a thickness of 50-180 μm, a ceramic layer 3 with a thickness of 50um-80um, a sealing coating 4 with a thickness of 5um-15um, The reflective layer 5 with a thickness of 5um-15um, the catadioptric layer 6 with a thickness of 5um-15um and the insulating layer 7 with a thickness of 10um-25um.

[0048] Wherein the composition of bonding layer 2 is one or more alloys in platinum (Pt), palladium (Pd), rhodium (Rh), ruthenium (R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com