Overall expansion-joint device for fuel assembly skeleton

A fuel assembly and expansion technology, applied in the directions of feeding device, positioning device, storage device, etc., can solve the problems of low production efficiency, large human error, complicated operation, etc., and achieve the same expansion effect, prevent deviation, avoid The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

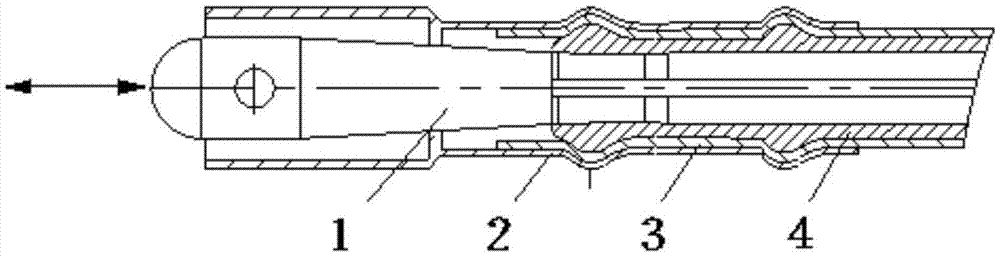

[0030] An overall expansion joint device for a fuel assembly skeleton, comprising an expansion joint assembly 5, a lifting assembly 6, a support 7, and a positioning assembly 8, wherein the support 7 is located at the lowest end to support the entire expansion joint device, and the lifting assembly 6 is arranged on the support 7 to lift and lower The component 6 can be lifted and lowered, and drives the expansion component 5 and the positioning component 8 to lift together. The positioning component 8 is arranged at the front end of the lifting component 6. The positioning component 8 is used for positioning the position to be expanded. The expansion assembly 5, the expansion assembly 5 includes several expansion pipes, and each expansion pipe can complete an expansion independently.

[0031] As the load-bearing frame of each component of the overall expansion joint, the bracket has good stability and strength, ensuring that the various mechanisms installed on it run smoothly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com