Ultralimit titanium alloy and preparation method thereof

A titanium alloy, ultra-limit technology, applied in the direction of metal material coating process, superimposed layer plating, special surface, etc., can solve the problems that titanium alloy cannot meet the use, achieve good bonding effect, increase the use temperature, and use The effect of increasing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is further described in detail through specific implementation methods:

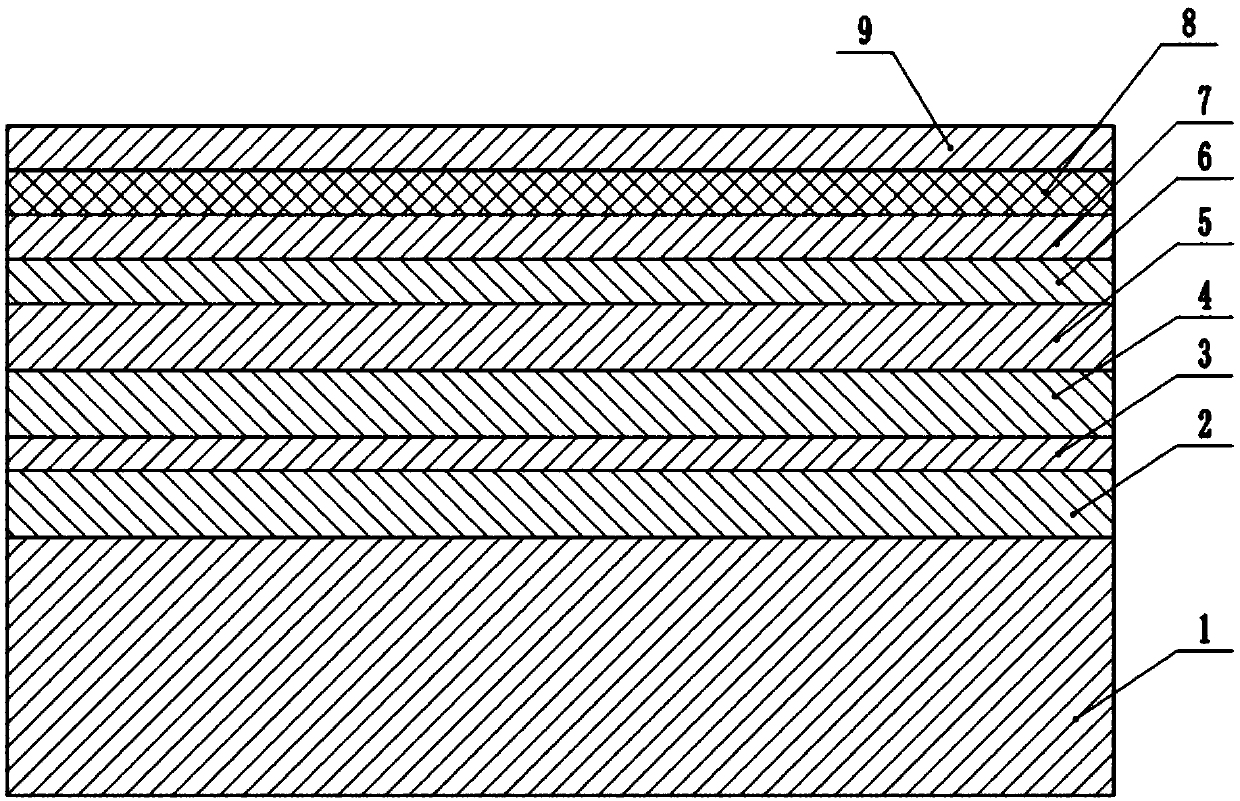

[0045] The reference signs in the accompanying drawings include: titanium alloy substrate 1, bonding layer 2, precious metal layer 3, ceramic A layer 4, ceramic B layer 5, reflective layer 6, catadioptric layer 7, insulating layer 8, foamed carbon layer 9.

[0046] The invention provides an ultra-limit titanium alloy, such as figure 1 As shown, including titanium alloy substrate 1, the surface of titanium alloy substrate 1 is sequentially deposited with a composite bonding layer, a composite ceramic layer with a thickness of 100-150 μm, a reflective layer 6 with a thickness of 10-30 μm, and a reflective layer with a thickness of 20-30 μm. 7. An insulating layer 8 with a thickness of 100-200 μm and a carbon foam layer 9 with a thickness of 20-200 μm. Wherein the composite adhesive layer is an adhesive layer 2 deposited on the surface of the titanium alloy substrate 1 and a precious ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com