Martensitic stainless steel and manufacturing method thereof

A technology of martensitic stainless steel and manufacturing method, which is applied in the field of iron and steel metallurgy, can solve the problems of decreased corrosion resistance, increased cost of raw materials, low solid solubility, etc., and achieves good corrosion resistance, low production cost, and good processing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Smelt the steel ingot with a vacuum induction furnace, place the steel ingot in the heating furnace, raise the temperature at 80°C / hour to 1250°C, and keep it for 3.5 hours; then forge it into a 40mm thick steel billet in the temperature range of 900-1200°C; then hot-roll into a 5mm thick steel plate; then conduct heat treatment; finally measure the performance.

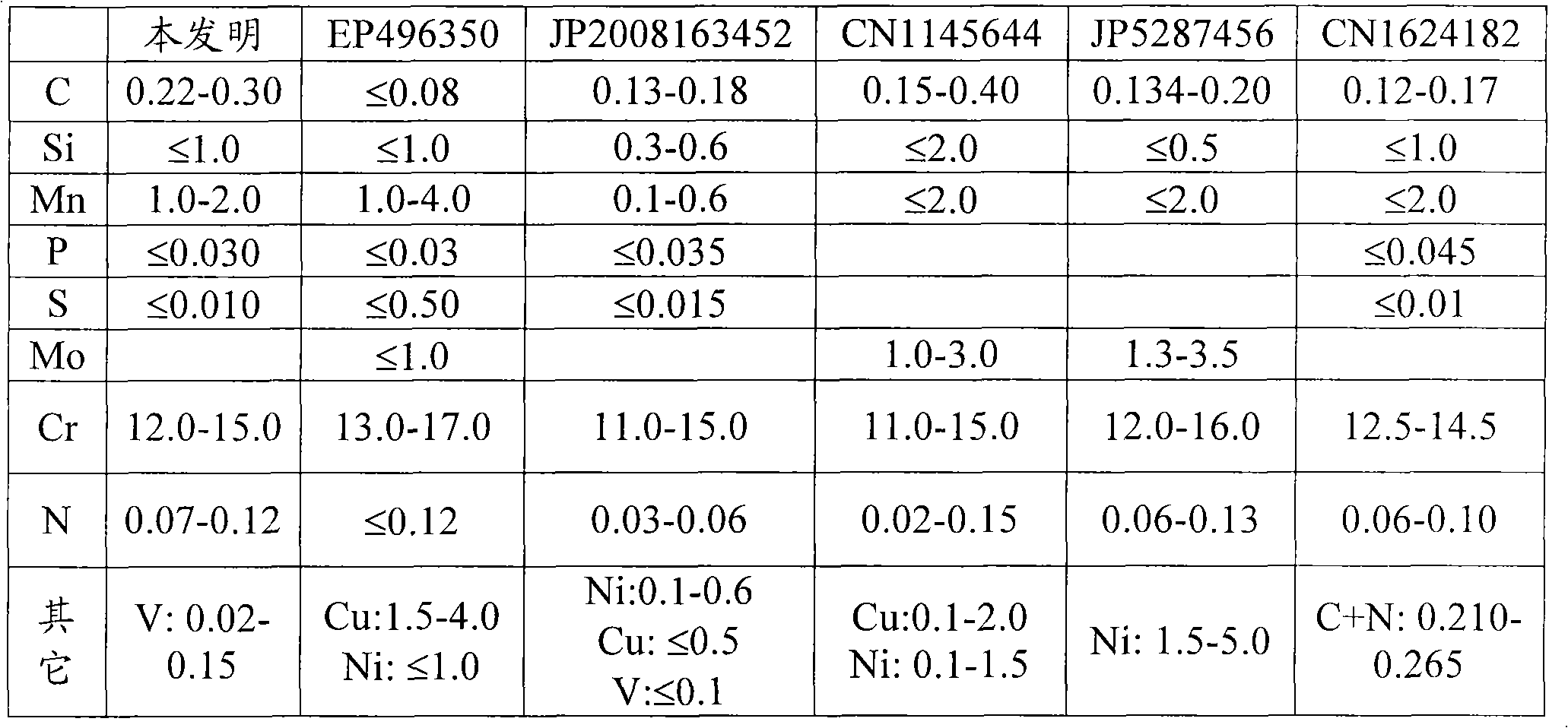

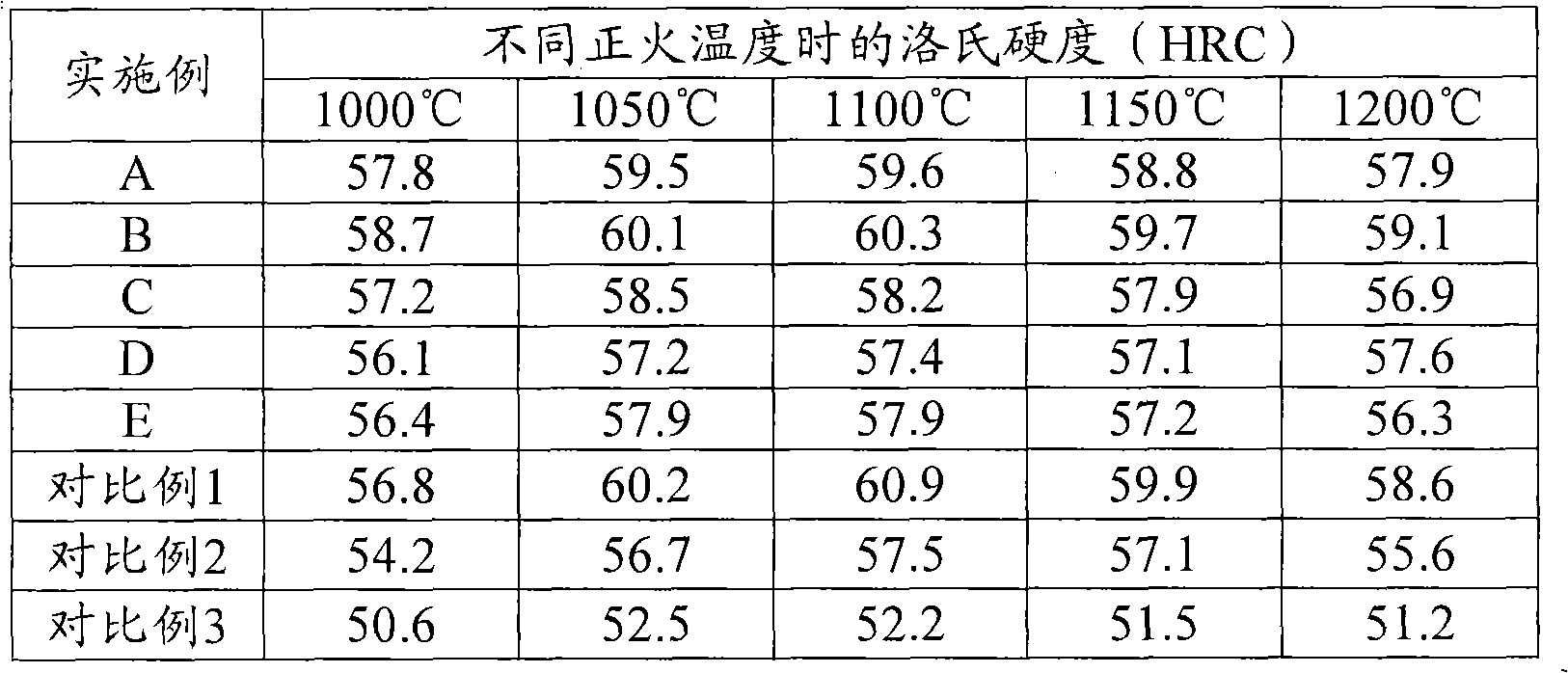

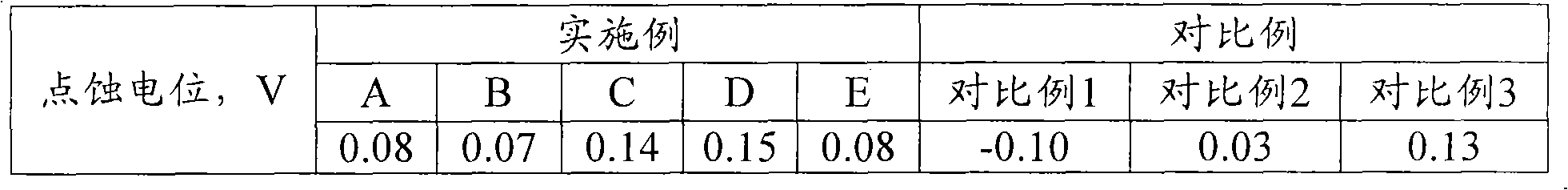

[0038] The specific chemical composition, preparation process and processability, hardness and corrosion resistance of the examples and comparative examples are shown in Tables 2-5 respectively, wherein Comparative Example 1, Comparative Example 2 and Comparative Example 3 are typical 4Cr13, 3Cr13 and 2Cr13 steels respectively ; Represent embodiment A-E of the present invention in table 3, its yield strength is less than 370MPa, maximum tensile strength is 660MPa, elongation is greater than 27.5%, has good processability; Among the table 4, the Rockwell hardness of embodiment A-E after normalizing Reaching abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com