High-stiffness high-strength heat-sealing embossed film and preparation method thereof

An embossed film, high-strength technology, applied in chemical instruments and methods, flexible coverings, film/sheet adhesives, etc., can solve problems such as poor temperature resistance, low stiffness, and many raw materials. Achieve excellent processing performance and maintain extrusion stability

Active Publication Date: 2012-10-10

佛山新长盛塑料薄膜有限公司

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the current composite plastic flexible packaging materials generally have the disadvantage of being thicker, and the raw materials used are more and the cost is higher.

[0003] In addition, in order to reduce the cost of materials, the thickness of the cast film is often thinner, and the mechanical properties of the cast film are correspondingly reduced with the thickness. During the processing and use of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

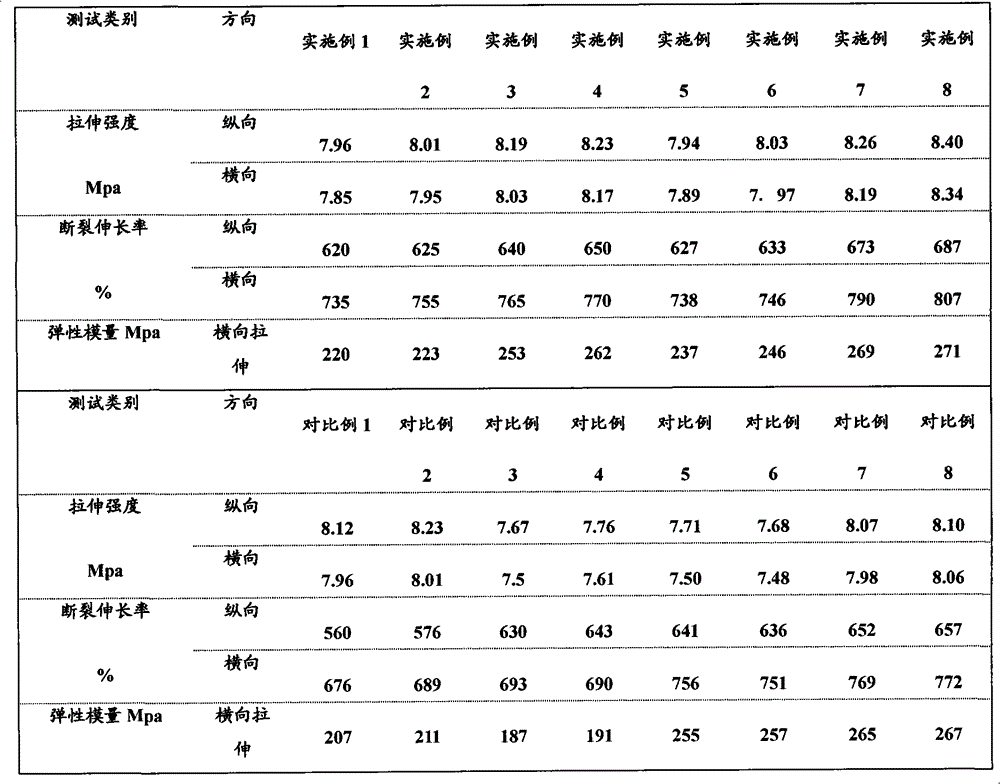

The invention relates to a high-stiffness high-strength heat-sealing embossed film and a preparation method thereof, in particular to a thin film applied to a curtain coating technology. The densities of film layers are controlled through components, and the deformation trend of each layer of the three-layer coextruded curtain coating film embossed film is optimized by refining processing technique, so as to obtain the high-stiffness high-strength heat-sealing embossed film. The embossed film has the advantages of great elastic modulus, high tensile strength, good heat-sealing property and excellent processing property. The thickness can be effectively reduced when the embossed film is used, so as to save cost. The embossed film can be used on occasions highly requiring anti-pollution heat-sealing.

Description

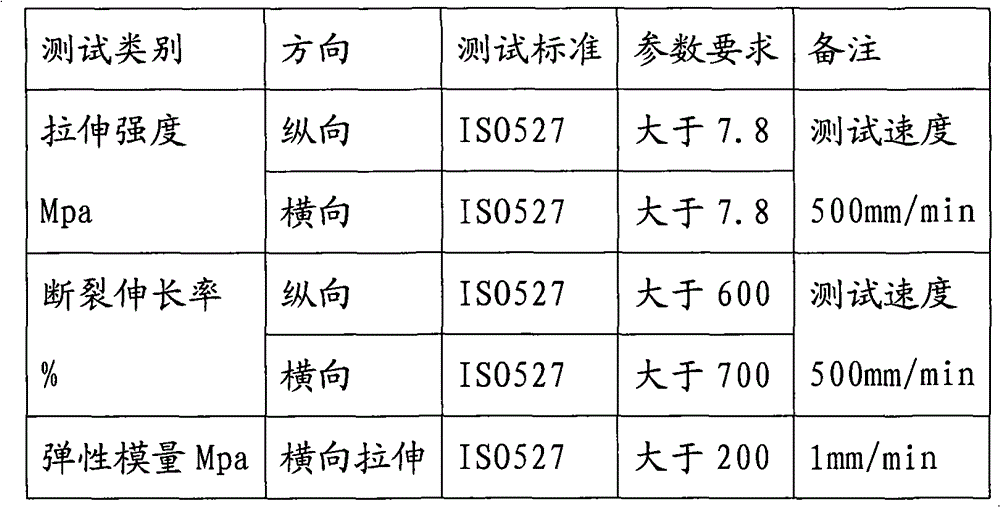

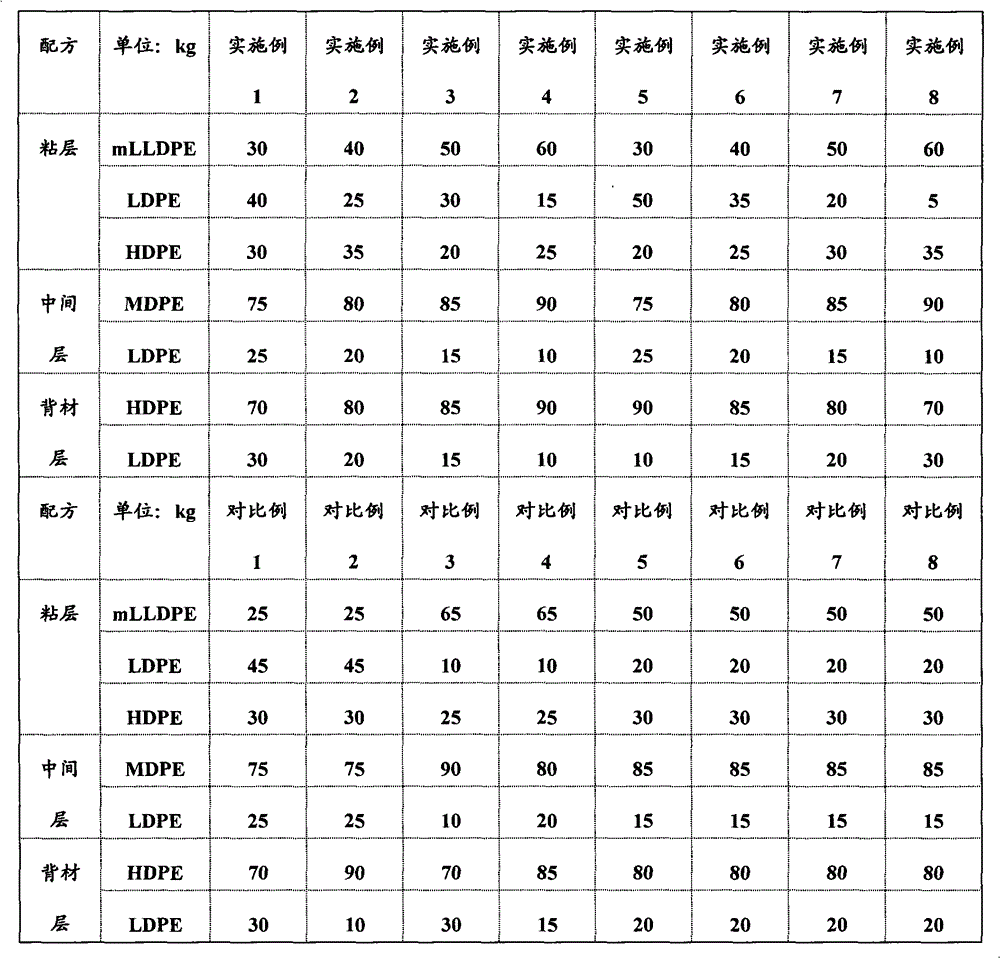

technical field [0001] The invention relates to a high-definition, high-strength heat-sealing performance embossed film and a preparation method thereof, in particular to a film prepared by a casting embossing process. Background technique [0002] Most of the composite plastic flexible packaging materials are composed of several layers of film, generally composed of film layers with different functions, for example: the adhesive layer provides heat sealing performance, usually blown polyethylene (IPE) film , cast polyethylene (CPE) film, cast polypropylene (CPP) film and EVA (ethylene-vinyl acetate copolymer) film; the substrate layer provides good mechanical properties and functional properties, generally biaxially stretched polyester film (BOPET), biaxially oriented nylon film (BOPA), biaxially oriented polypropylene film (BOPE), coated polyvinylidene chloride film (PVDC), polyvinyl alcohol film (PVA), aluminum foil, paper, etc. have good barrier properties s material. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J7/02C09J123/08C09J123/06B32B27/08B32B27/32B29C69/00B29C47/06B29C59/04B65D65/40

Inventor 戴涛

Owner 佛山新长盛塑料薄膜有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com