Corrosion resistant spring steel with tensile strength of more than or equal to 2100 MPa and production method thereof

A 2100mpa, tensile strength technology, used in low internal friction springs, springs/shock absorbers, mechanical equipment, etc., can solve the problems of no corrosion resistance, the tensile strength of spring steel has not been significantly improved, and achieve good The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

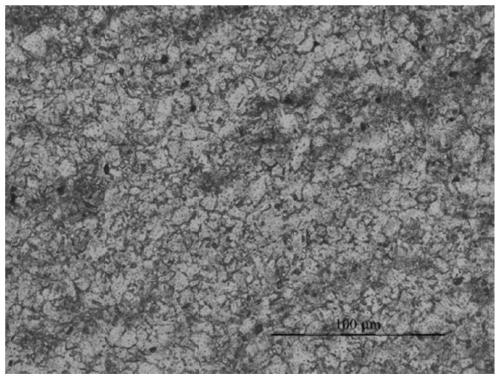

Image

Examples

Embodiment Construction

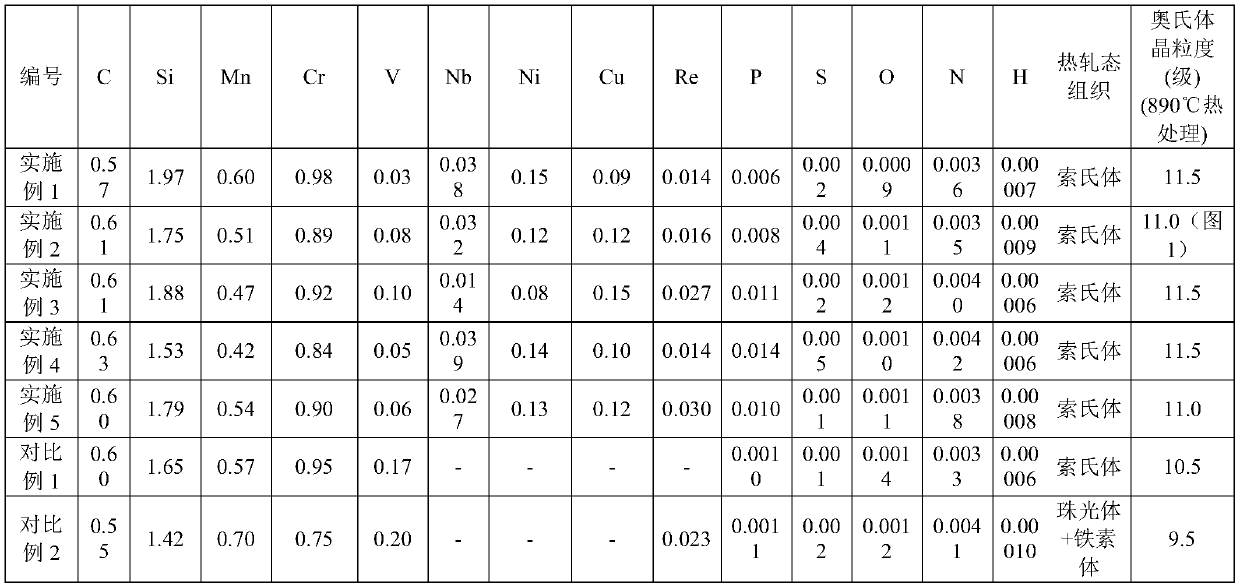

[0037] The present invention will be further described below in conjunction with embodiment. The described examples and their results are only for illustrating the invention, but should not and will not limit the invention as detailed in the claims.

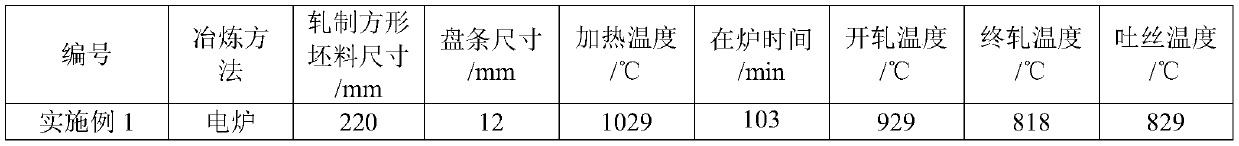

[0038] Each embodiment of the present invention is all produced by following process:

[0039] (1) Conventional electric furnace or converter smelting: Oxygen is fixed before tapping, and slag is strictly controlled during tapping;

[0040] (2) Conventional refining furnace refining: C, Si, Cr, Mn, V, Nb, Ni, Cu, Re and other elements are adjusted to the target value;

[0041] (3) Vacuum degassing: the pure degassing time is ≥15 minutes, and the [H] content after vacuum treatment is guaranteed to be ≤1.5ppm;

[0042] (4) Continuous casting: control the target temperature of molten steel in the tundish to be 10-40°C above the liquidus temperature, and continuously cast 150mm×150mm-250mm×250mm billets;

[0043] (5) Wire rod roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com