Special twin screw unload device and unload method for adult diapers and adult incontinence trousers

An adult incontinence trousers, twin-screw technology, which is applied in the direction of absorbent pads, etc., can solve the problems of inability to apply relatively accurately and quantitatively, and the addition amount is limited, and achieves the effects of simple structure, uniform delivery and good interchangeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

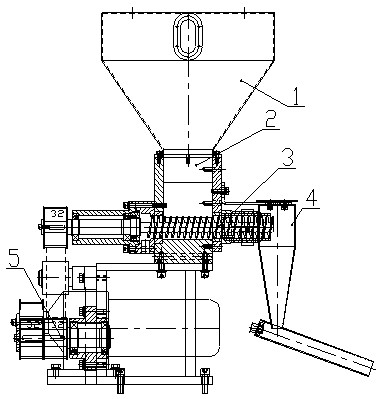

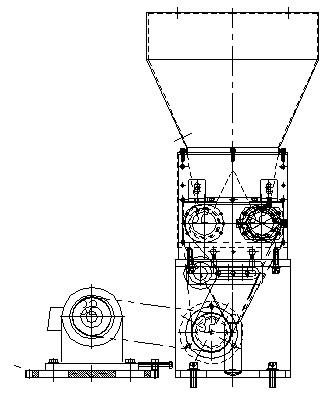

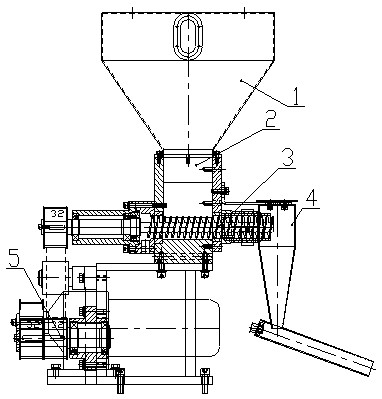

[0010] Embodiment 1: with reference to attached figure 1 and 2 . Special twin-screw feeding device for adult diapers and adult incontinence pants. The polymer pump is installed on the silo 1. The outlet of the silo 1 is connected to the material box 2. The lower part of the material box 2 is horizontally opened with double holes that penetrate the wall of the material box. Screw installation hole, twin-screw rod 3 traverses the twin-screw rod installation hole of hopper 2 bottom, one end of its twin-screw rod 3 is driven by motor to rotate through bridge assembly 5, and the other end communicates with discharge hopper 4 through twin-screw passage.

[0011] The outlet of the hopper 4 is connected with an angle-adjustable material guide pipe to meet the requirements of polymer application.

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, the feeding method of the special twin-screw feeding device for adult diapers and adult incontinence pants, the polymer pump pumps the polymer into the silo 1 and passes through the silo 1. The feed port enters the material box 2, and since the surface of the twin-screw 3 is just opposite to the outlet of the material box 2, the polymer entering the material box 2 directly falls on the twin-screw 3, and the twin-screw 3 is driven by the motor through the bridge assembly 5. The screw timing belt rotates and the macromolecules are sent into the discharge hopper 4, so that the macromolecules and cotton cores enter the molding box together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com