Double-copper-electrode rectifying tube chip made of coated environment-friendly material, and coating process

A technology of environmentally friendly materials and layers of environmentally friendly materials, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as hidden environmental pollution, waste of rare resources, and no quality improvement, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] 1. Several materials and accessories are purchased by outsourcing. Such as: according to the set resistivity, the set thickness, the set diffusion junction depth and concentration, the surface of the nickel-plated round silicon wafer with rectification characteristics can be 3 inches or 4 inches in diameter; the set thickness and Oxygen-free copper circle electrode with diameter; brazed circle piece with set thickness and diameter.

[0045] 2. Use a wire cutting machine to cut silicon wafers into circular, regular hexagonal, or square single silicon wafers.

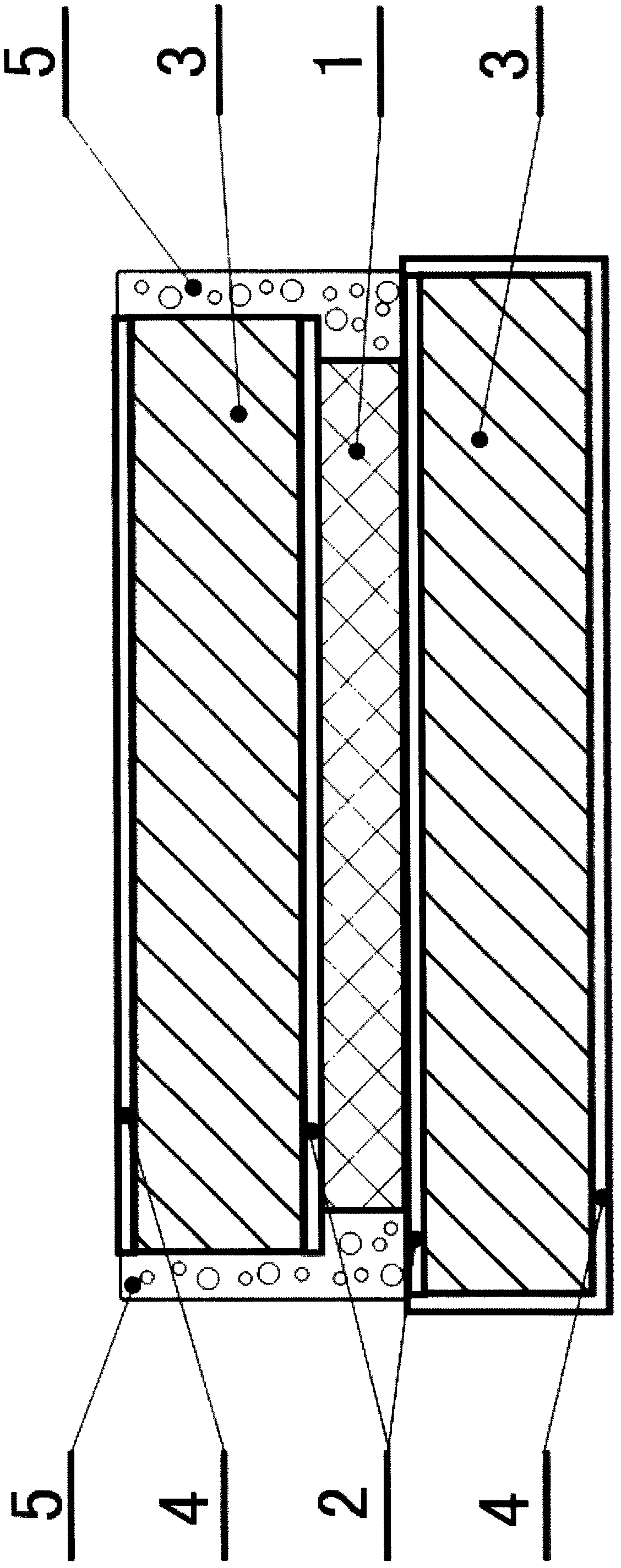

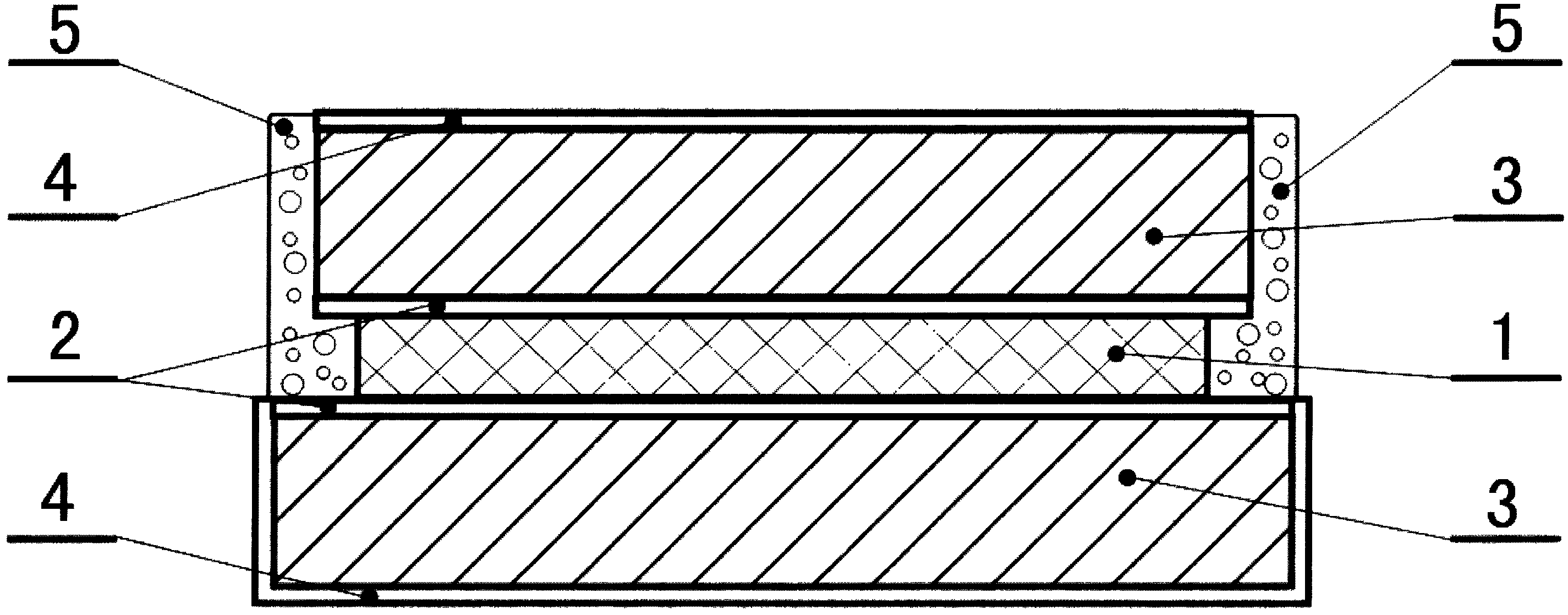

[0046] 3. Put the silicon chip, brazing sheet and copper electrode in accordance with the instruction manual. figure 1 The structures shown are stacked in sequence, loaded into a sintering mold, pushed into a vacuum sintering furnace, and sintered into a quasi-product entity.

[0047] 4. Use a mixed etching solution of hydrofluoric acid, nitric acid, glacial acetic acid, and sulfuric acid to etch the vertical edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Geometry | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com