High-strength high-damping magnesium alloy containing rare-earth elements

A technology of rare earth elements and high damping, which is applied in the field of high-strength and high-damping magnesium alloys and high-damping magnesium alloys to achieve the effects of improving alloy strength, refining grain size, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

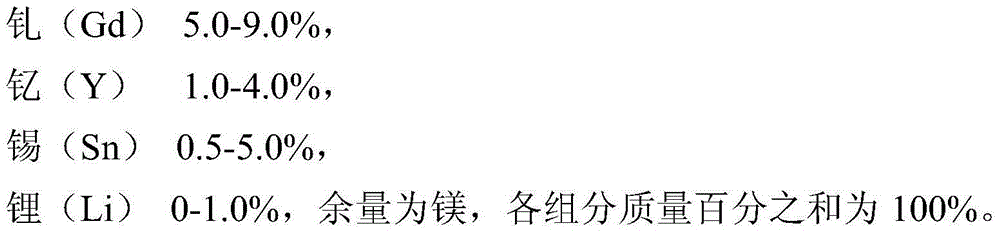

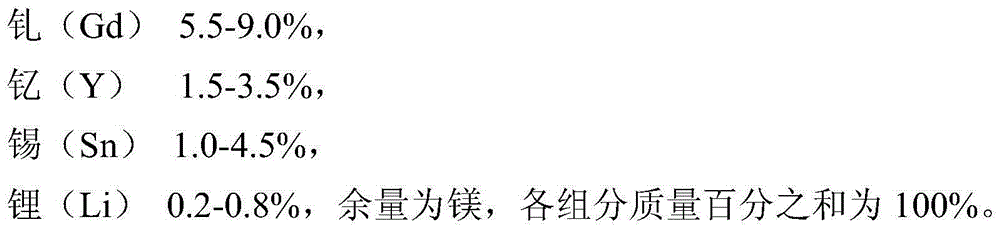

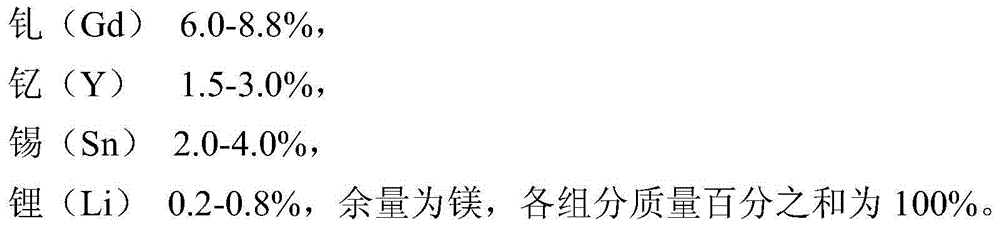

Method used

Image

Examples

Embodiment

[0030] The present invention provides 10 kinds of alloys with different component ratios. After casting, solution quenching and artificial aging, the alloy components, mechanical properties and damping performance indexes are shown in Table 1.

[0031] The preparation process of the alloy in the embodiment of the present invention is as follows: according to the 1-10 kinds of alloy components determined in Table 1, the components of the alloy are distributed, Mg is added in the form of pure magnesium, and other elements are added in the form of an intermediate alloy. Smelting in the interior, the melt is passed through Ar 2After degassing, pouring and cooling into ingots, the melting and pouring temperatures of the alloy are 780°C and 740°C respectively. Aging at ℃ / 16h to obtain a high-strength and high-damping magnesium alloy.

[0032] For the prepared high-strength and high-damping magnesium alloy, the damping performance test is carried out according to GB / T18258-2000;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com