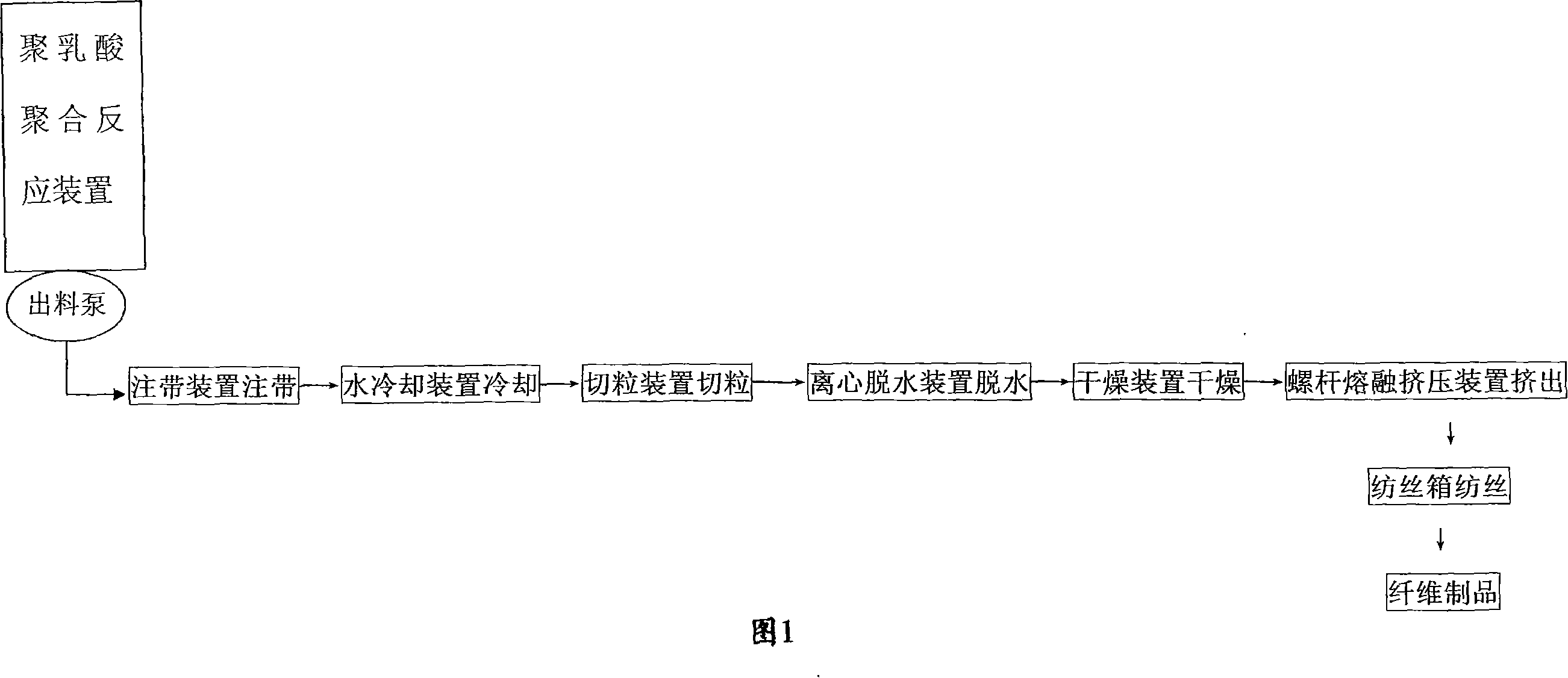

Method for direct preparation of fiber product from polylactic acid polymerized melt

A fiber product, polylactic acid technology, applied in the application field of new polymer materials, can solve problems such as restricting the industrialization process of fiber products, and achieve the effect of ensuring spinnability, quality, and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

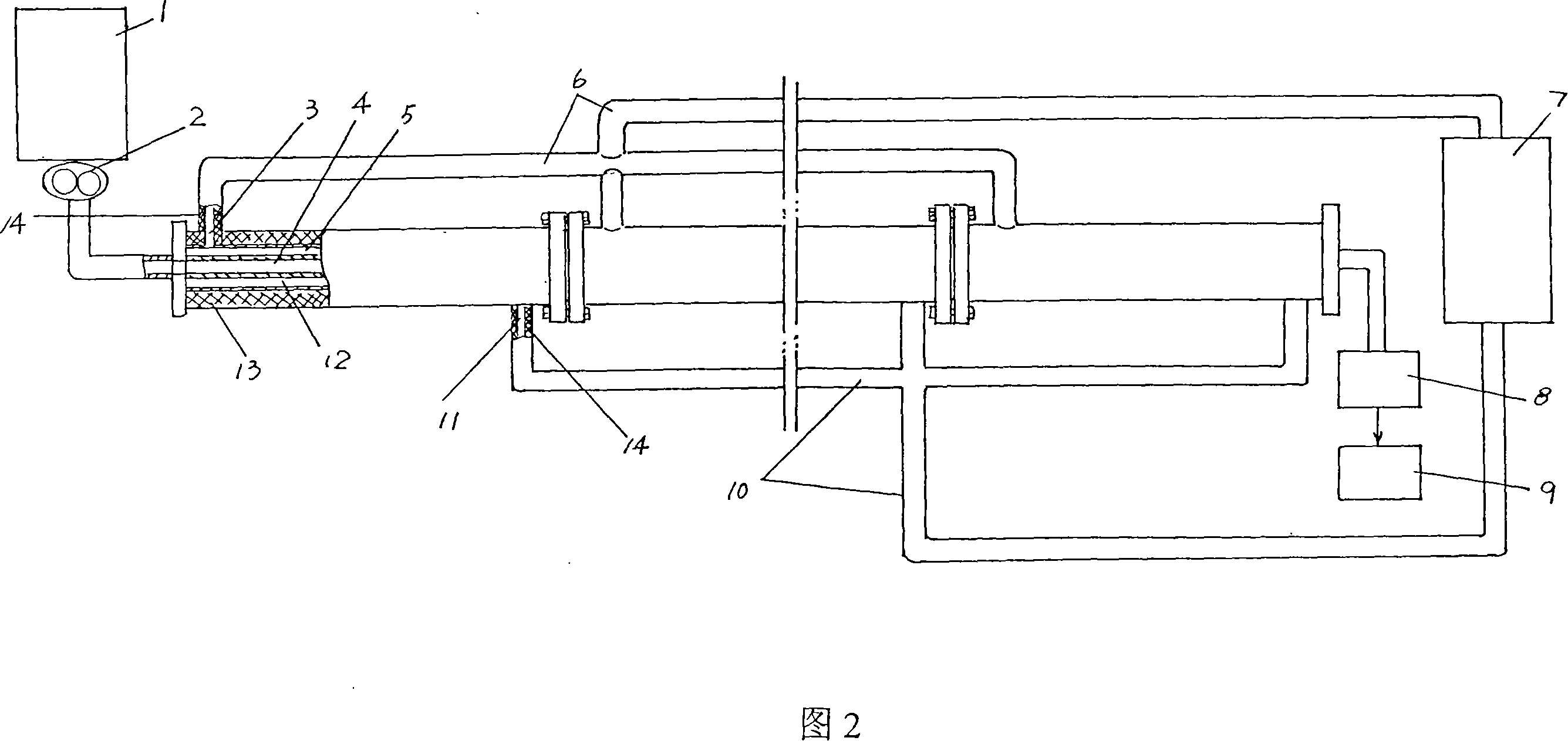

[0026] Please refer to Fig. 2, the main raw material lactide (LA) and trace initiator are prepared polylactic acid polymerization reaction device ring-opening polymerization reaction such as disclosed by Chinese patent CN1884337A, CN1884338A and when the end of the reaction in the termination device Add a small amount of end-capping agent, heat stabilizer and acid scavenger, and the viscous polymer obtained after the reaction is completed at a process temperature of 235°C, that is, polylactic acid polymer melt, passes through a discharge pump 2 connected to the final device 1 The melt conveyor with a linear distance of 180m between the outlet of the outlet and the inlet of the spinning box 8 heats the polylactic acid polymer melt and keeps it at 235°C and continuously introduces it into the spinning box 8 at a pressure of >2MPa. , the continuously introduced polylactic acid melt is continuously spun by a spinning box 8 to obtain a fiber product 9 . For the discharge pump 2, it...

Embodiment 2

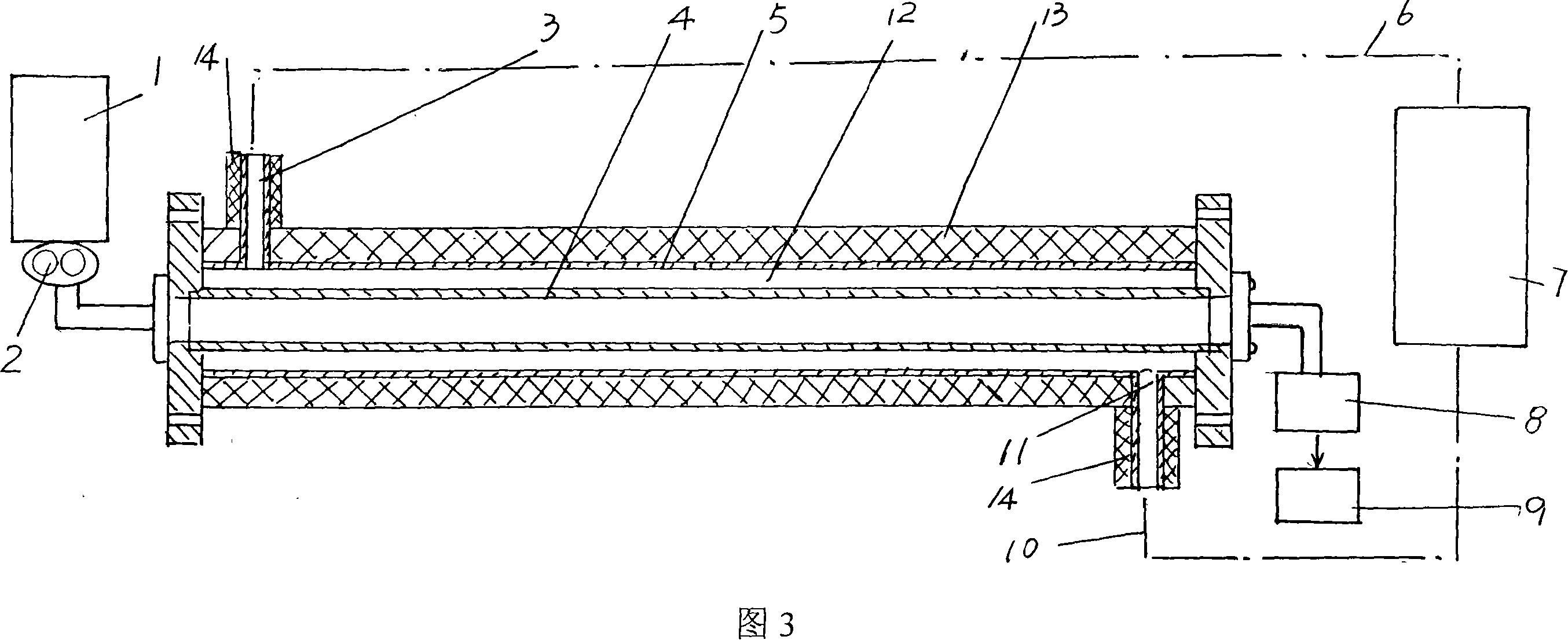

[0032] See Figure 3. From the discharge pump 2 connected to the finishing device 1, the polylactic acid polymerized melt with a temperature of 210°C obtained after the polymerization reaction of the polymerization reaction device is terminated is directly sent to the spinning through the melt conveying pipe 4 with a linear distance of 20 meters. Box 8, the temperature of the spinning box is controlled at about 210 ° C, the temperature of the heat transfer oil in the spacer 5 is the same as the temperature of the polylactic acid polymer melt, and the fiber products spun from the spinning box 8, that is, the polylactic acid fiber products, are processed through the subsequent process. After the process is oiled, it is continuously drawn by the feeding roller to the drafting hot roller, and after being drawn 3 to 6 times, it is continuously wound up on the bobbin of the winding system to become FDY filament or undergo air deformation treatment to become BCF filament. It can be di...

Embodiment 3

[0034] See Figure 4. The polylactic acid polymerized melt with a temperature of 220°C obtained after the polymerization reaction of the polymerization reaction device is terminated by the discharge pump 2 connected to the final device 1 is directly sent to the spinning through the melt conveying pipe 4 with a linear distance of 100 meters. Box 8, the temperature of the spinning box body is controlled at about 220°C, the outer wall of the spacer 5 is wound with an electric heating ribbon 15 with sufficient power as an electric heating element, and the outer surface of the electric heating ribbon 15 is covered by the first thermal insulation material 13, and the outer wall of the spacer 5 The cavity 12 is filled with heat transfer oil 19. When the heat transfer oil heats up, due to the volume change due to thermal expansion, the expanded heat transfer oil 19 enters the high-level expansion tank 18 through the pipeline 17 through the overflow port 16 communicating with the spacer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com