Antiskid wax for surfboards and its preparation method

A surfboard, anti-skid technology, applied in chemical instruments and methods, other chemical processes and other directions, can solve the problems of difficult to apply discontinuous coating, poor anti-skid effect of anti-slip wax, difficult to coat with anti-slip wax, etc., to achieve convenient use. , good effect, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

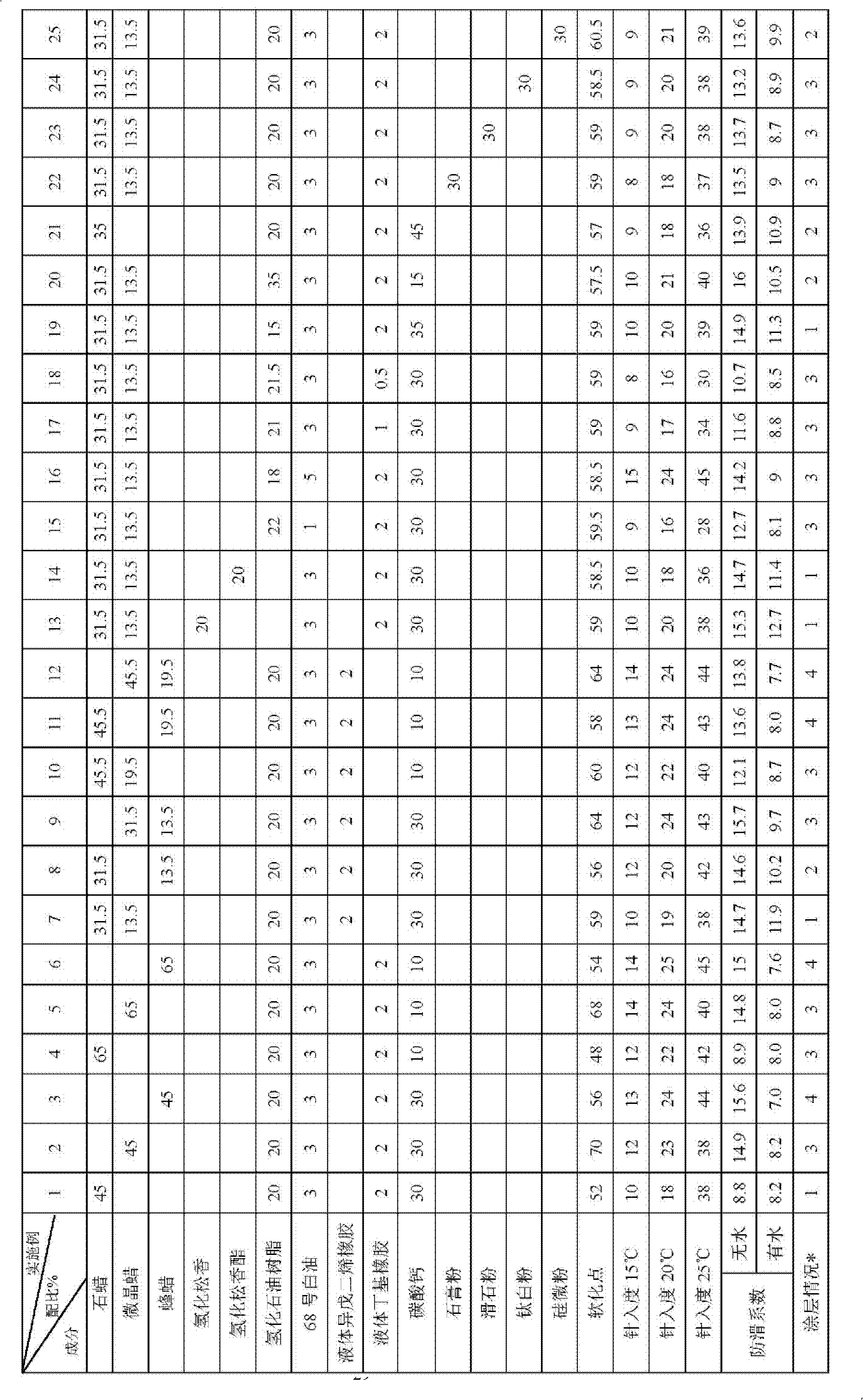

Examples

preparation example Construction

[0043] The preparation method of the anti-skid wax for surfboards of the present invention, first heat and melt the waxy substance and keep it at 120°C; add tackifying resin to melt completely; cool down to 100°C, add tackifier and plasticizer, and stir at low speed for more than 60 minutes ;Stir at 100°C while slowly adding inorganic fillers, and stir at constant temperature for more than 120 minutes after adding; discharge and cool to form anti-skid wax for surfboards.

[0044] After adding the inorganic filler and stirring at a constant temperature, add pigments and / or spices, stir for 10 minutes, discharge and cool to form anti-skid wax for surfboards.

[0045] The heating, melting and holding time of the waxy substance is 20 minutes; the speed of the low-speed stirring is 30 rpm, and the stirring time is 60-90 minutes; the speed of the constant temperature stirring is 60 rpm, and the stirring time for 120-150 minutes.

[0046] Among the present invention, anti-skid coeff...

Embodiment 1

[0054] First heat and melt 40% of the waxy substance, and keep it at 120°C, add 20% of the tackifying resin to melt completely; cool down to 100°C, add 2% of the tackifier and 3% of the plasticizer, and stir at a speed of 30 rpm For 60 minutes, keep stirring at 100°C while slowly adding 35% of inorganic fillers. After adding, stir at a constant temperature of 60 rpm for 120 minutes, then add 0.3% of spices and 0.1% of pigments and continue stirring for 10 minutes. Anti-slip wax for surfboards.

[0055] Among them, the wax substance is paraffin; the tackifying resin is hydrogenated petroleum resin; the tackifier is liquid butyl rubber; the plasticizer is No. 68 white oil; the inorganic filler is calcium carbonate with a fineness of 1500 meshes.

[0056] The softening point of the anti-skid wax for surfboards is 52°C, the penetration (15°C, 100g, 0.1mm): 10, the penetration (20°C, 100g, 0.1mm): 16, the penetration (25°C , 100g, 0.1mm): 28.

[0057] The coating is a discontinuo...

Embodiment 2

[0059] First heat and melt 40% of the waxy substance, and keep it at 120°C, add 20% of the tackifying resin to melt completely; cool down to 100°C, add 2% of the tackifier and 3% of the plasticizer, and stir at a speed of 30 rpm For 60 minutes, keep stirring at 100°C while slowly adding 35% of inorganic fillers. After adding, stir at a constant temperature of 60 rpm for 120 minutes, then add 0.3% of spices and 0.1% of pigments and continue stirring for 10 minutes. Anti-slip wax for surfboards.

[0060] Among them, the wax substance is microcrystalline wax; the tackifying resin is hydrogenated petroleum resin; the tackifier is liquid butyl rubber; the plasticizer is No. 68 white oil; the inorganic filler is calcium carbonate with a fineness of 1500 meshes.

[0061] The softening point of the anti-skid wax for surfboards is 74°C, the penetration (15°C, 100g, 0.1mm): 12, the penetration (20°C, 100g, 0.1mm): 20, the penetration (25°C , 100g, 0.1mm): 33.

[0062] About 50% of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com