Auxiliary agent for reactive coating and printing ink and its synthesis method

A reactive, coating technology, applied in the direction of coating, can solve problems such as affecting the adhesion of aluminum plating, reducing surface tension, improving shrinkage cavities, etc., to avoid affecting adhesion, preventing paint film shrinkage, and reducing surface tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

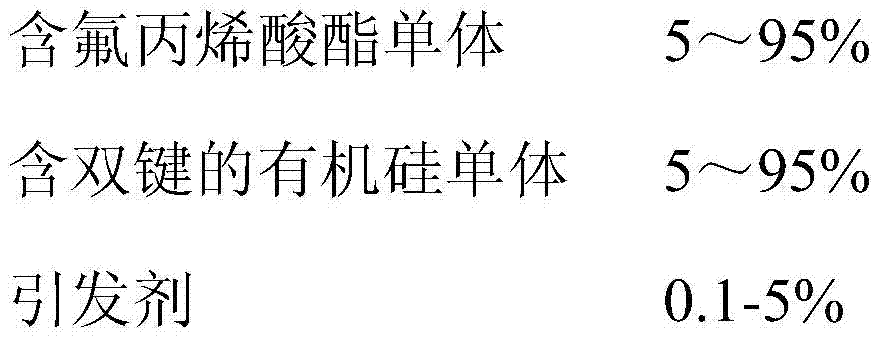

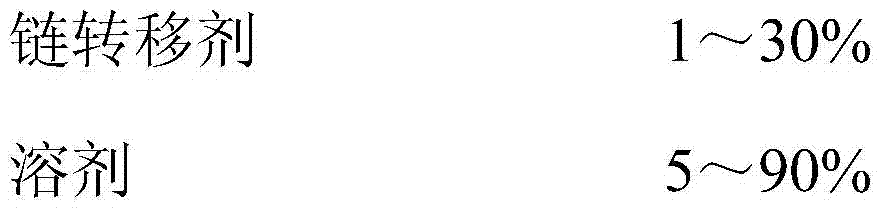

[0044] A reactive coating and ink additives, mainly synthesized by free radical solution copolymerization process of the following raw materials in weight percentage:

[0045]

[0046] The total amount of the above components is 100%.

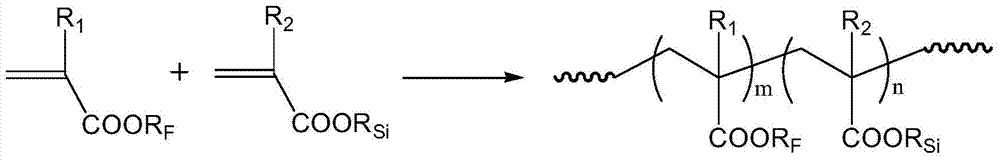

[0047] The fluorine-containing acrylate monomer is trifluoroethyl (meth)acrylate, hexafluorobutyl (meth)acrylate, dodecafluoroheptyl (meth)acrylate, nonadenofluoroheptyl acrylate or perfluoroalkyl acrylate ester.

[0048] The double bond-containing silicone monomer is a silicone resin with acryloxy or methacryloxy, wherein the acryloxy or methacryloxy may be at the end or branch of the silicone monomer.

[0049] The radical copolymerization initiator is one of azobisisobutyronitrile, azobisisoheptonitrile, benzoyl peroxide, tert-butyl peroxide, and di-tert-amyl peroxide.

[0050] The chain transfer agent is one of mercaptoethanol, mercaptopropanol, and dodecyl mercaptan.

[0051] The solvent is one or more of benzene, toluene, xylene, propylene glycol me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com