Cooling water tank for rapidly solidifying high-purity aluminum-silicon alloy

An aluminum-silicon alloy and cooling water tank technology is applied in the field of cooling water tanks for rapidly solidifying high-purity aluminum-silicon alloys. Aluminum-silicon alloys are prone to shrinkage cavities and other problems, which can improve the cooling effect, improve the pouring efficiency, and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

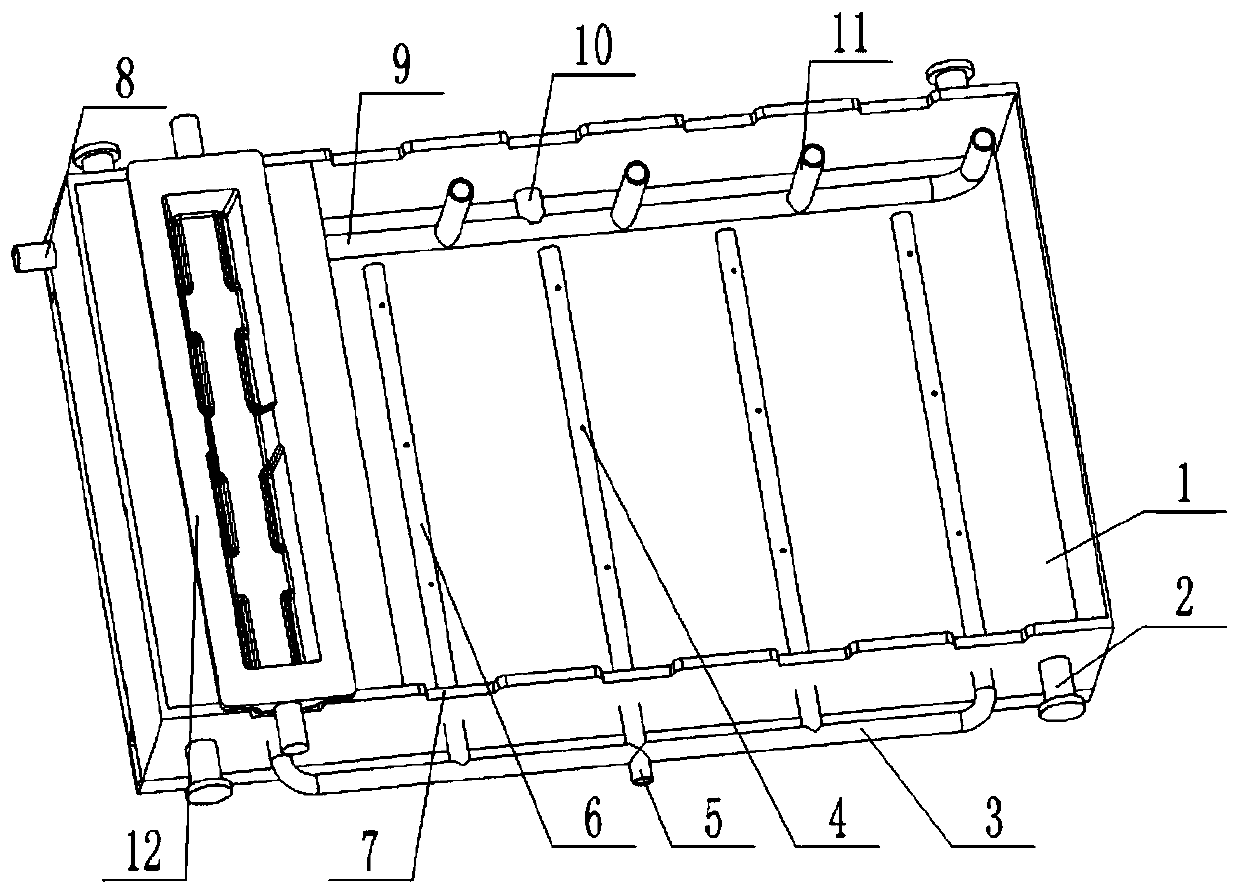

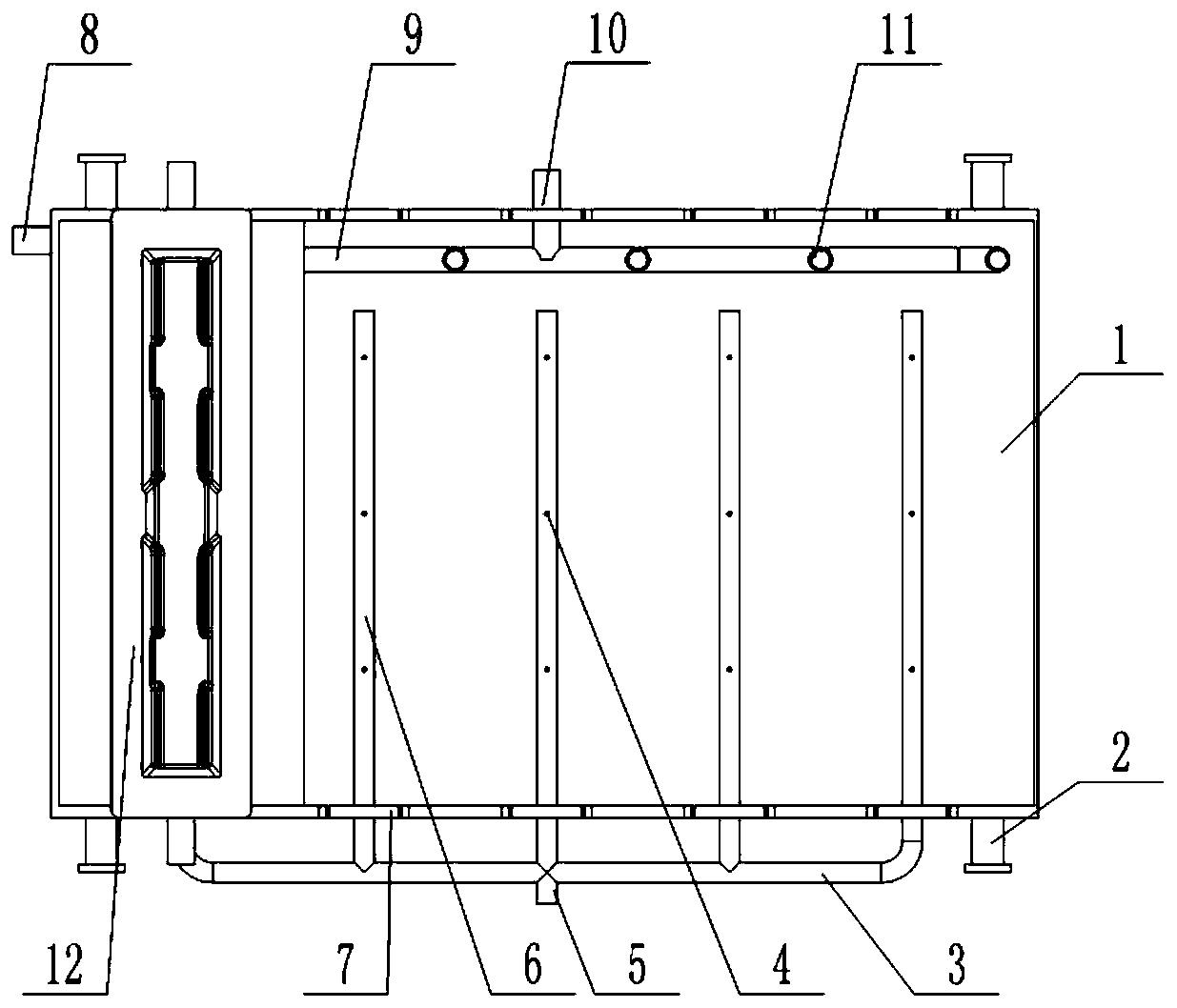

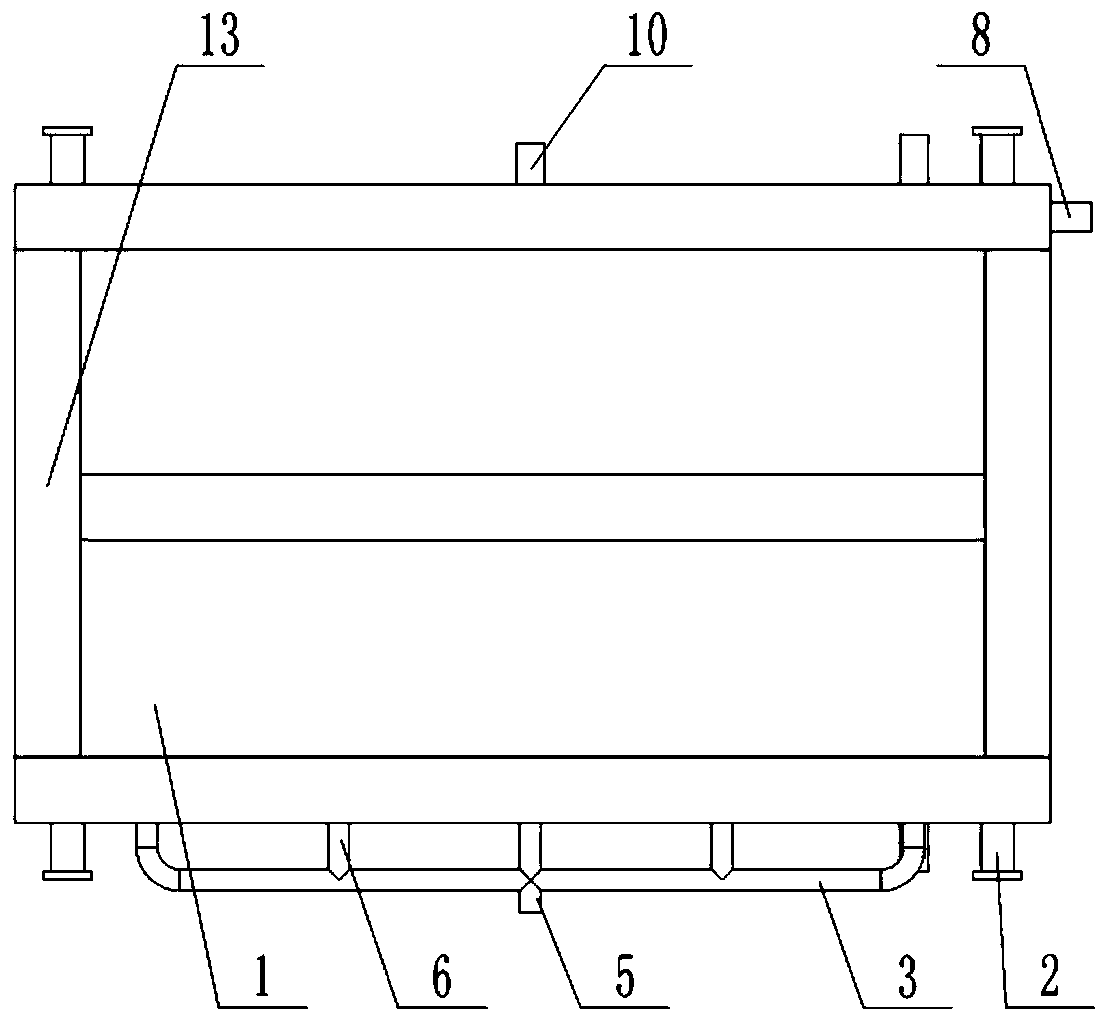

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0019] Such as Figure 1-6 As shown, a cooling water tank for rapid solidification of high-purity aluminum-silicon alloys includes a water tank main body 1 with an opening on one side, and is characterized in that a plurality of lifting lugs 2 are fixedly fixed on the front and rear side walls of the water tank main body 1, so that On the side wall of the opening end of the water tank main body 1, several alloy ingot placement grooves 7 are arranged side by side. The water outlet structure and the water inlet structure, the water inlet structure includes the water inlet pipe 5 arranged outside the front side of the water tank main body 1, the water outlet end of the water inlet pipe 5 is vertically fixed with the water inlet main pipe 3, and the water inlet main pipe 3 is vertically fixed with several parallel and equidistant water inlet branch pipes 6, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com