PDU relay adhesion detection circuit and method and automobile operation control method

A technology for detecting circuits and detection methods, applied in electric vehicles, circuit breaker testing, measuring current/voltage, etc., can solve problems such as system battery and electronic control damage, and achieve the effect of protecting the battery box with low possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

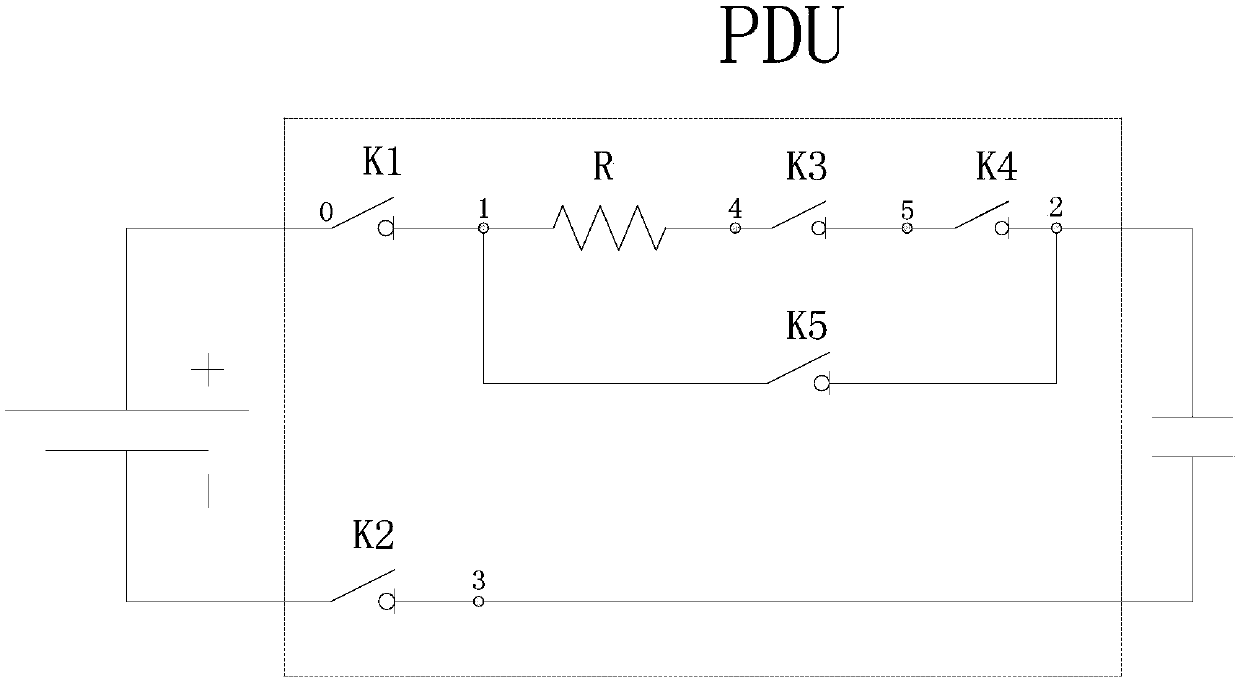

[0037] Such as figure 1 and figure 2 As shown, a PDU relay adhesion detection circuit in Embodiment 1 of the present invention includes a battery box, a main relay K5, a capacitor, a pre-charging resistor R, a first pre-charging relay K3 and a second pre-charging relay K4,

[0038] One end of the main relay K5 is electrically connected to the positive terminal of the battery box, and the other end of the main relay K5 is electrically connected to one end of the capacitor; the other end of the capacitor is electrically connected to the negative terminal of the battery box. extreme;

[0039] One end of the pre-charging resistor R is electrically connected to the common end of the battery box and the main relay K5, and the other end of the pre-charging resistor R is electrically connected to one end of the first pre-charging relay K3; The other end of the first pre-charging relay K3 is electrically connected to one end of the second pre-charging relay K4; the other end of the ...

Embodiment 2

[0042] Embodiment 2 of the present invention is a PDU relay adhesion detection circuit. On the basis of Embodiment 1, a first protection relay K1 is connected in series between the common end of the pre-charging resistor R and the main relay K5 and the battery box. .

Embodiment 3

[0043] Embodiment 3 of the present invention is a PDU relay adhesion detection circuit. On the basis of Embodiment 2, a second protection relay K2 is connected in series between the capacitor and the battery box.

[0044] By adding a dual-circuit protection relay, it can ensure that the back-end load has no high voltage after power failure and avoid component damage.

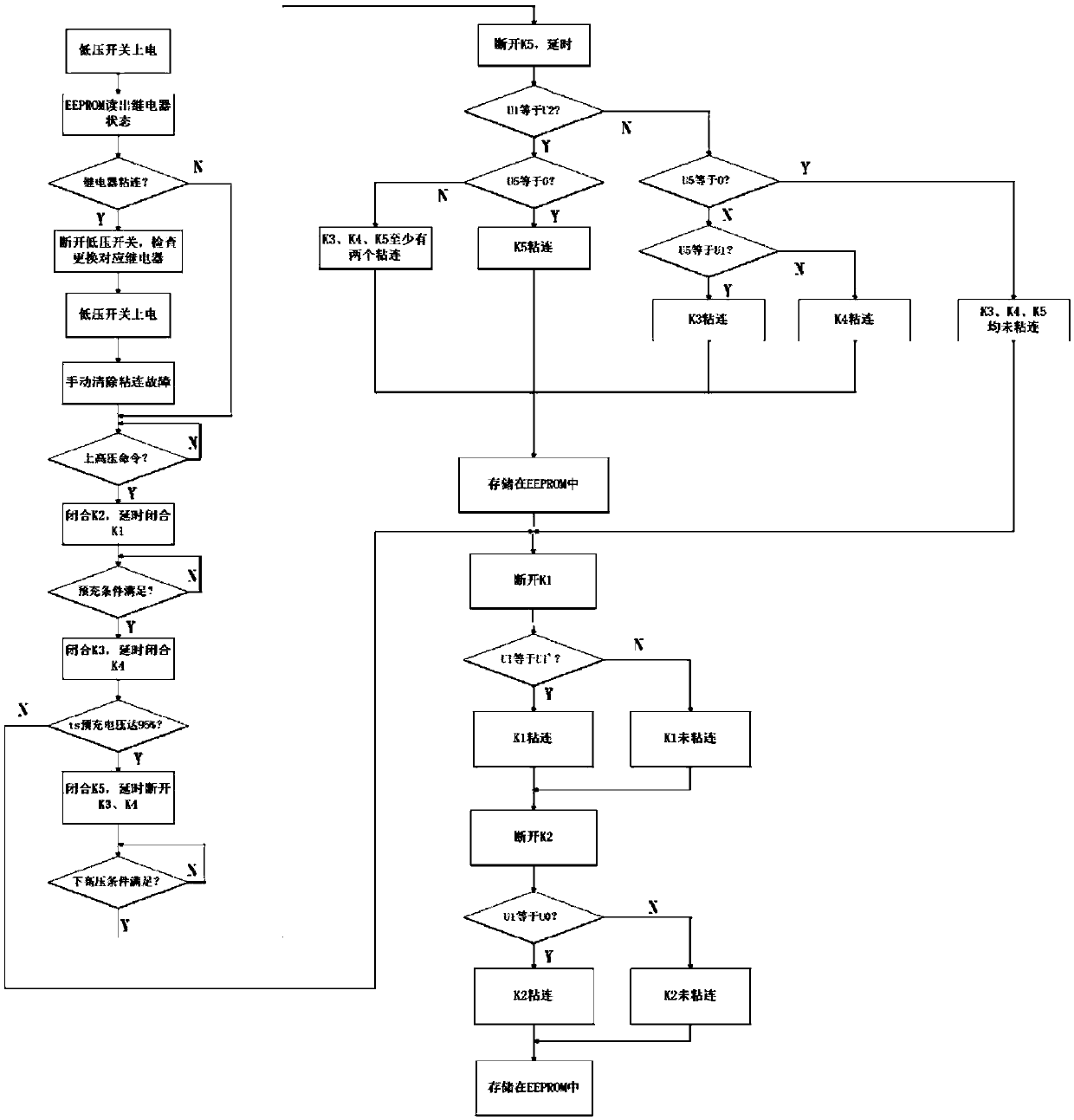

[0045] The power-on sequence of the first protection relay K1 and the second protection relay K2 is: after the low-voltage power-on, first detect the adhesion state of the relay, if the relay is not adhered and there is a high-voltage command, then control the first protection relay K1 and the second protection relay. The second protection relay K2 pulls in, and then waits for the pre-charging conditions to be met before starting pre-charging and powering up the load with high voltage; therefore, it needs to receive the relay status and request a high-voltage command before it can pull in the first protective rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com