Waterproof concrete and preparation method thereof

A technology of waterproof concrete and waterproofing agent, which is applied in the field of concrete, can solve the problems of concrete corrosion, etc., and achieve the effect of improving impermeability and acid corrosion resistance, good impermeability, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

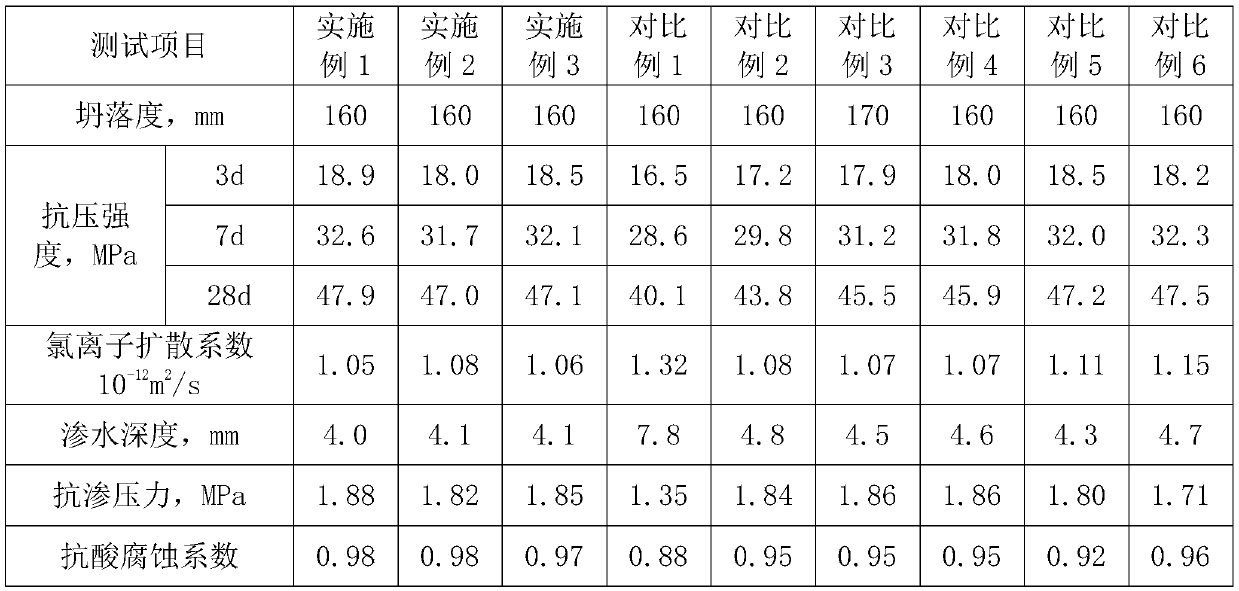

Examples

preparation example 1

[0035] Preparation example 1 of modified basalt fiber: 1. Pretreatment Place basalt fiber in 10wt% sodium hydroxide solution and soak for 1 hour, then take it out and wash it with water to neutrality, and obtain pretreated basalt fiber after drying;

[0036] ②Preparation of calcined stone powder; take kaolinite and wollastonite with a weight ratio of 3:1, crush and grind them through a 200-mesh sieve to obtain mixed stone powder; place the mixed stone powder in a high-temperature furnace at 5°C / min Raise the temperature to 500°C at a high speed, calcined for 1 hour, then raised the temperature to 1200°C at a speed of 10°C / min, calcined for 4 hours, and obtained calcined stone powder after cooling;

[0037] ③ Preparation of modifier: Grinding calcined stone powder and silane coupling agent with a weight ratio of 50:1 to obtain modifier;

[0038] ④Take 20kg of pretreated basalt fiber and 50kg of ethanol solution with a volume fraction of 50%, stir for 5-10min, add 4kg of modifie...

preparation example 2

[0039] Preparation example 2 of modified basalt fiber: 1. Pretreatment Put basalt fiber in 10wt% sodium hydroxide solution and soak for 1.5h, then take it out and wash it with water to neutrality, and obtain pretreated basalt fiber after drying;

[0040] ②Preparation of calcined stone powder; take kaolinite and wollastonite with a weight ratio of 3:1, crush and grind them through a 200-mesh sieve to obtain mixed stone powder; place the mixed stone powder in a high-temperature furnace at 5°C / min Raise the temperature to 550°C at a speed of 1.5 hours, then raise the temperature to 1250°C at a speed of 10°C / min, calcinate for 5 hours, and obtain calcined stone powder after cooling;

[0041] ③ Preparation of modifier: Grinding calcined stone powder and silane coupling agent with a weight ratio of 50:1 to obtain modifier;

[0042] ④ Take 25kg of pretreated basalt fiber and 75kg of ethanol solution with a volume fraction of 50%. After stirring for 7.5 minutes, add 5kg of modifier, r...

preparation example 3

[0043] Preparation example 3 of modified basalt fiber: 1. Pretreatment Put basalt fiber in 10wt% sodium hydroxide solution and soak for 2 hours, then take it out and wash it with water to neutrality, and obtain pretreated basalt fiber after drying;

[0044] ②Preparation of calcined stone powder; take kaolinite and wollastonite with a weight ratio of 3:1, crush and grind them through a 200-mesh sieve to obtain mixed stone powder; place the mixed stone powder in a high-temperature furnace at 5°C / min Raise the temperature to 600°C at a high speed, calcining for 2 hours, then raise the temperature to 1300°C at a speed of 10°C / min, calcining for 6 hours, and obtain calcined stone powder after cooling;

[0045] ③ Preparation of modifier: Grinding calcined stone powder and silane coupling agent with a weight ratio of 50:1 to obtain modifier;

[0046] ④ Take 30kg of pretreated basalt fiber and 100kg of ethanol solution with a volume fraction of 50%. After stirring for 10 minutes, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com