Device for automatic piston phosphatization

A piston and automatic technology, applied in the direction of metal material coating process, can solve the problems of unguaranteed piston phosphating quality, poor flow effect, affecting piston phosphating quality, etc. Simple and easy to debug effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings.

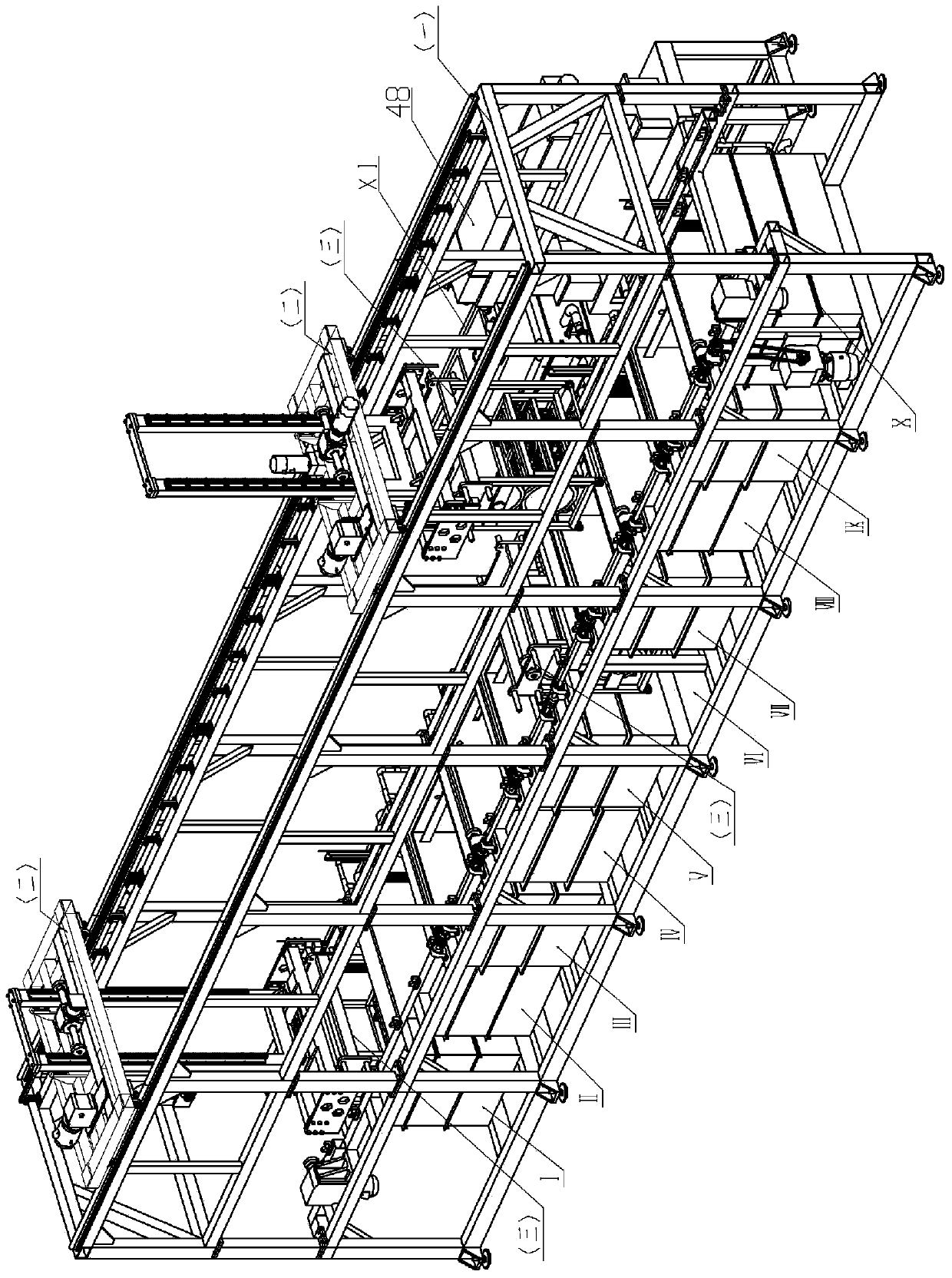

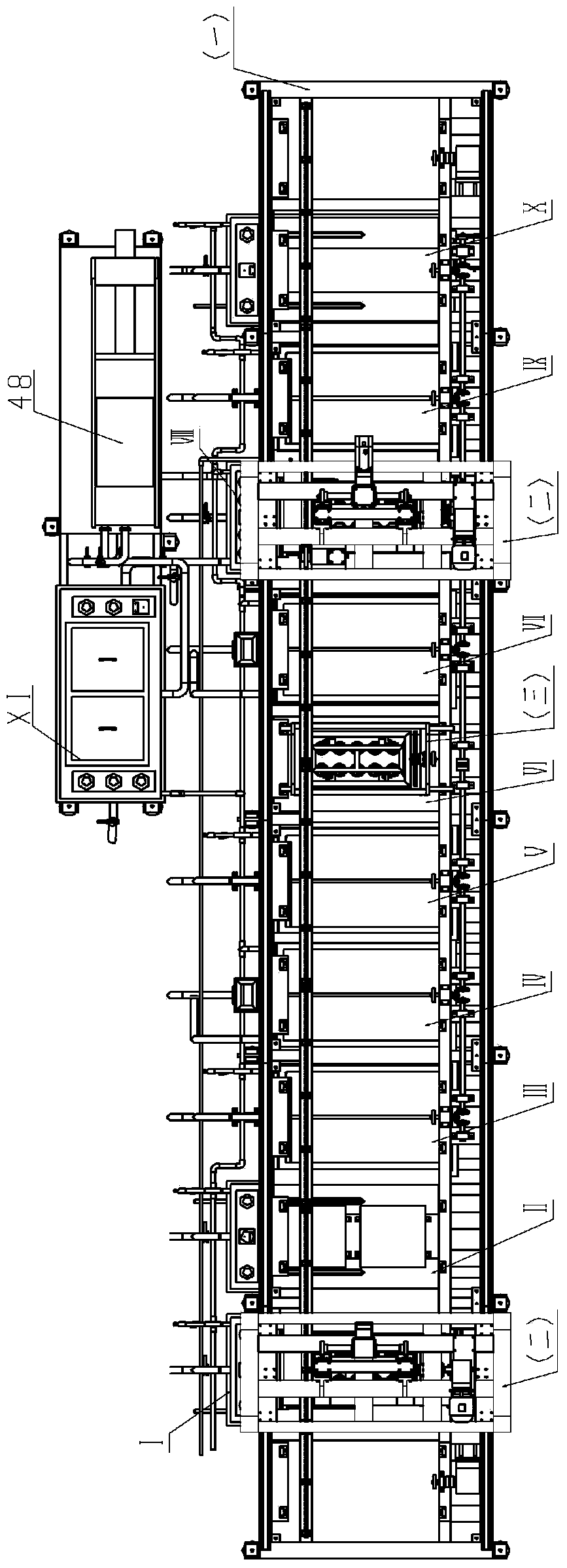

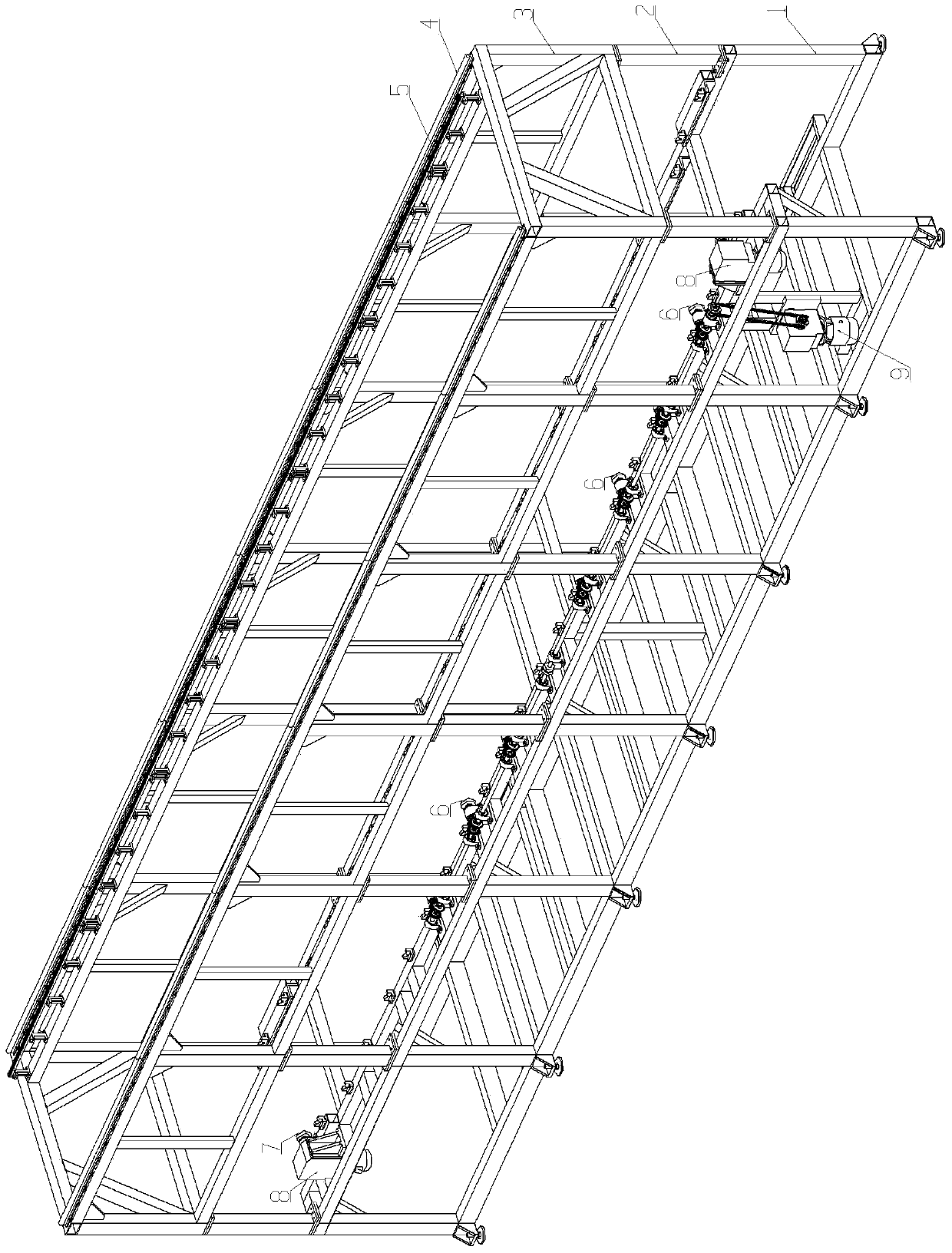

[0065] figure 1 , figure 2 It is the overall assembly diagram of the present invention, which includes the main body frame 1, the manipulator 2, the rotating hanger 3, the phosphating process tank (ultrasonic cleaning tank Ⅰ, ultrasonic cleaning tank Ⅱ, rinsing tank Ⅲ, pickling tank Ⅳ, rinsing tank Ⅴ, table Adjusting tank VII, phosphating tank VIII, rinsing tank IX, hot water washing tank X, phosphating tank XI) and filter press 48. Two slide rails 4 are installed on the top surface of the main frame one. The roller 29 of the manipulator two is fixed on the slide rails 4. The manipulator two drives the rotating hanger three according to the phosphating process. After staying in each groove for a certain period of time, it automatically moves to the bottom. a slot. When the rotating hanger 3 falls into the groove, the gear III53 meshes with the gear VII 6 to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com