Four-in-one phosphating solution and preparation method thereof

A phosphating solution and phosphoric acid technology, which is applied in the coating process of metal materials, etc., can solve the problems of large corrosion of workpieces, harsh working conditions, poor corrosion resistance of too thin film layers, etc., and achieve improved phosphating efficiency and complete lattice arrangement , The effect of excellent paint adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

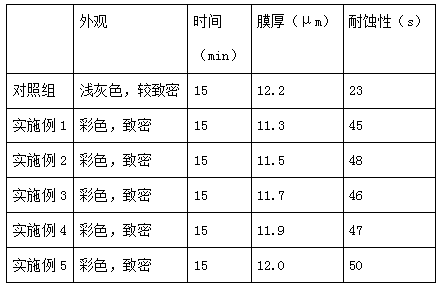

Examples

Embodiment 1

[0027] Example 1 A four-in-one phosphating solution is composed of the following components: 85% phosphoric acid 10g / L, sodium dihydrogen phosphate 30g / L, sodium tripolyphosphate 0.5g / L, antirust agent 0.1g / L L, stabilizer 0.33 g / L, ammonium molybdate 0.8 g / L, pH regulator 1 g / L, water 1 L.

[0028] The preparation method of above-mentioned a kind of four-in-one phosphating solution, the steps are as follows:

[0029] (1) Weigh the required raw materials according to the formula ratio;

[0030] (2) First add 550mL of water to the reaction kettle, then add 85% phosphoric acid and sodium dihydrogen phosphate to the stainless steel reaction kettle in turn, slowly raise the temperature to 46°C, then add ammonium molybdate while stirring, and wait until the ammonium molybdate After the addition, continue to stir for 12 minutes, then raise the temperature to 70°C, add sodium tripolyphosphate, and stir thoroughly to obtain the base liquid;

[0031] (3) Add the remaining water to th...

Embodiment 2

[0032] Example 2 A four-in-one phosphating solution is composed of the following components: 85% phosphoric acid 30g / L, sodium dihydrogen phosphate 40g / L, sodium tripolyphosphate 1g / L, antirust agent 0.3g / L , 0.46 g / L stabilizer, 1.2 g / L ammonium molybdate, 2 g / L pH regulator, 1 L water.

[0033] The preparation method of above-mentioned a kind of four-in-one phosphating solution, the steps are as follows:

[0034] (1) Weigh the required raw materials according to the formula ratio;

[0035] (2) First add 650mL of water to the reaction kettle, then add 85% phosphoric acid and sodium dihydrogen phosphate to the stainless steel reaction kettle in turn, slowly raise the temperature to 52°C, then add ammonium molybdate while stirring, and wait until the ammonium molybdate After the addition, continue to stir for 20 minutes, then raise the temperature to 78°C, add sodium tripolyphosphate, and stir thoroughly to obtain the base liquid;

[0036] (3) Add the remaining water to the b...

Embodiment 3

[0038] Example 3 A four-in-one phosphating solution is composed of the following components: 85% phosphoric acid 13g / L, sodium dihydrogen phosphate 33g / L, sodium tripolyphosphate 0.62g / L, antirust agent 0.17g / L L, stabilizer 0.36g / L, ammonium molybdate 0.93g / L, pH regulator 1.2g / L, water 1L.

[0039] The preparation method of above-mentioned a kind of four-in-one phosphating solution, the steps are as follows:

[0040] (1) Weigh the required raw materials according to the formula ratio;

[0041] (2) First add 600mL of water to the reaction kettle, then add 85% phosphoric acid and sodium dihydrogen phosphate to the stainless steel reaction kettle in turn, slowly raise the temperature to 48°C, then add ammonium molybdate while stirring, and wait until the ammonium molybdate After the addition, continue to stir for 15 minutes, then raise the temperature to 73°C, add sodium tripolyphosphate, and stir thoroughly to obtain the base liquid;

[0042] (3) Add the remaining water to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com