Rust-removing phosphating solution for wire rod drawing, and preparation method thereof

A phosphating liquid and wire technology, applied in the direction of metal material coating process, etc., can solve the problems of phosphating agent containing highly corrosive components, phosphating film is not strong enough, high cost of wastewater treatment, to achieve high thermodynamics, improve hardness , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

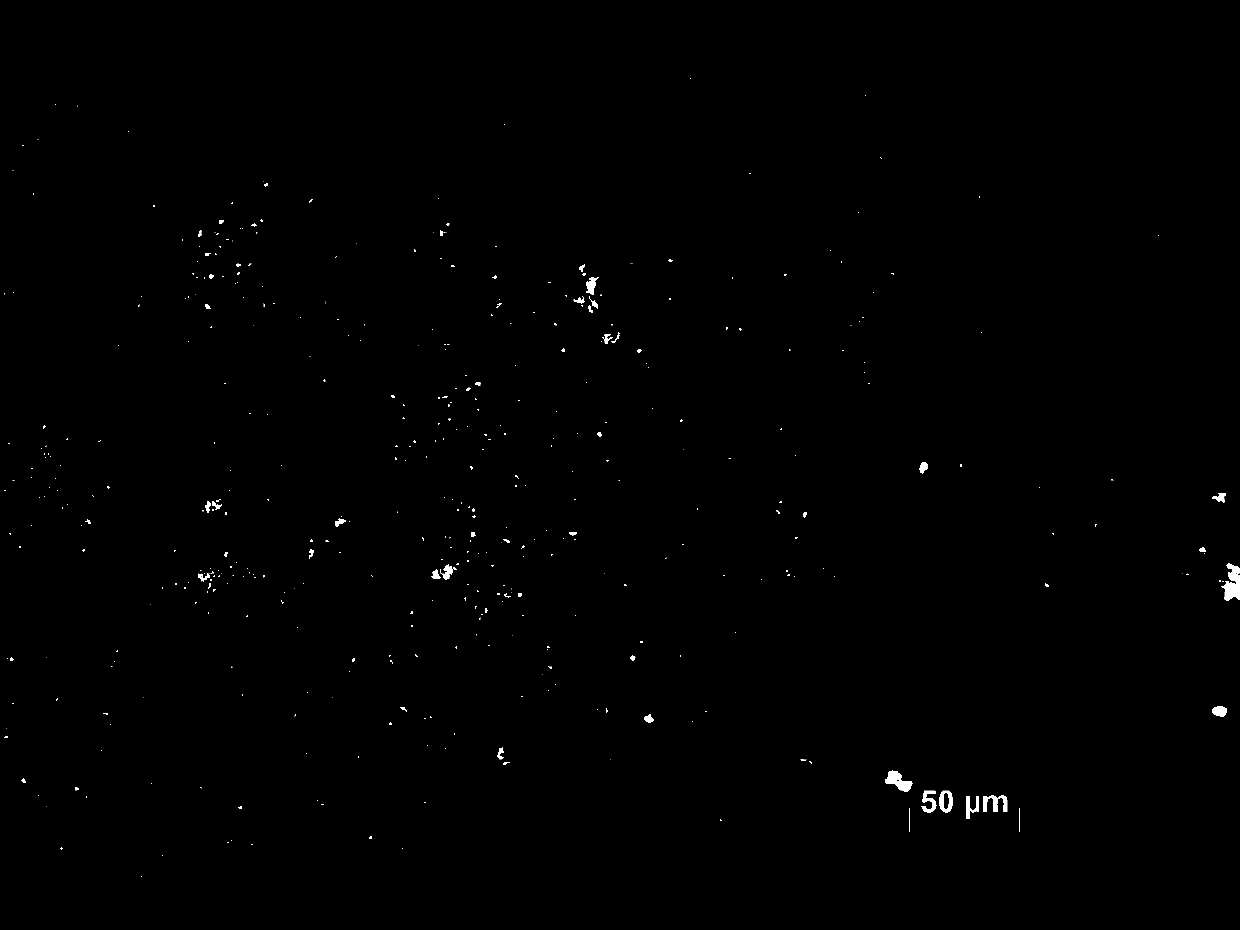

Image

Examples

Embodiment 1

[0036] A rust-removing phosphating solution for wire drawing, consisting of the following chemical components in mass percent:

[0037] Phosphoric acid 50%, nitric acid 1%, zinc oxide 5%, zinc dihydrogen phosphate 2%, zinc nitrate, nickel nitrate and ferrous nitrate 5%, manganese carbonate 2.5%, sodium fluoride 1.5%, citric acid 1.5%, perfluorinated Potassium octanesulfonate YF-95: 0.05%, water: 31.45%;

[0038] Wherein, the molar ratio of zinc nitrate, nickel nitrate and ferrous nitrate is 100:7:25.

[0039] At room temperature, take materials according to the above chemical composition distribution ratio, add zinc oxide, nitrate, manganese carbonate and complexing agent into water, stir until completely dissolved, then add dihydrogen phosphate, phosphoric acid, nitric acid and fluorine-containing surfactant , after fully stirring evenly, the product of rust removal and phosphating solution is obtained.

[0040] Place the workpiece to be treated in a 4-fold diluted rust rem...

Embodiment 2

[0042] A rust-removing phosphating solution for wire drawing, consisting of the following chemical components in mass percent:

[0043] Phosphoric acid 20%, nitric acid 10%, zinc oxide 10%, manganese dihydrogen phosphate 10%, zinc nitrate, nickel nitrate and ferrous nitrate 1%, manganese carbonate 0.5%, sodium fluoride 0.1%, tartaric acid 0.1%, perfluorooctyl quaternary ammonium iodide YF-134: 1%, water: 47.3%;

[0044] Wherein, the molar ratio of zinc nitrate, nickel nitrate and ferrous nitrate is 100:12:15.

[0045] At room temperature, take materials according to the above chemical composition ratio, add zinc oxide, nitrate, manganese carbonate and complexing agent into water, stir until completely dissolved, then add phosphoric acid, nitric acid, dihydrogen phosphate and fluorine-containing surfactant , after fully stirring evenly, the product of rust removal and phosphating solution is obtained.

[0046] Place the workpiece to be treated in a 4-fold diluted rust-removin...

Embodiment 3

[0048] A rust-removing phosphating solution for wire drawing, consisting of the following chemical components in mass percent:

[0049] Phosphoric acid 30%, nitric acid 5%, zinc oxide 1%, manganese dihydrogen phosphate 2.5%, zinc dihydrogen phosphate 2.5%, zinc nitrate, nickel nitrate and ferrous nitrate 10%, manganese carbonate 5%, alanine 3%, Citric acid 2%, YF-001 fluorocarbon high-efficiency leveling agent 0.5%, water: 38.5%;

[0050] Wherein, the molar ratio of zinc nitrate, nickel nitrate and ferrous nitrate is 10:1:2.

[0051] At room temperature, take materials according to the above chemical composition ratio, add zinc oxide, dihydrogen phosphate, nitrate, manganese carbonate and complexing agent into water, stir until completely dissolved, then add phosphoric acid, nitric acid and fluorine-containing surfactant , after fully stirring evenly, the product of rust removal and phosphating solution is obtained.

[0052]Place the workpiece to be treated in a 4-fold dilut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com