Door leaf manufacturing technique

A production process and door leaf technology, applied in metal material coating process, wing leaf frame, etc., can solve problems such as low cost, complexity and quality of door leaf production process, and achieve the effect of simplifying process steps, avoiding erosion, and protecting the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

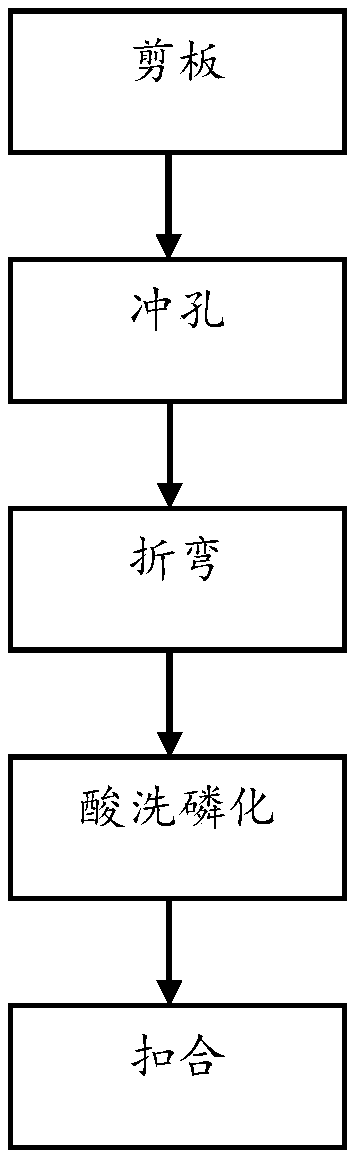

[0023] Such as figure 1 As shown, a kind of door leaf production process is provided, comprising the following steps:

[0024] Step 1: Cut the board, cut the board out of the pre-designed shape;

[0025] Step 2: Punching, after cutting the plate, use the punching device to punch the plate;

[0026] Step 3: Bending, using a bending machine to bend the punched plate;

[0027] Step 4: Pickling and phosphating the bent plate to remove grease, rust, and surface adjustment;

[0028] When removing grease, treat it in a low-alkaline cleaning agent. The low-alkaline cleaning agent is composed of inorganic low-alkaline additives, surfactants, and defoamers. The treatment temperature is 70 degrees and the treatment time is 40 minutes. It has a low alkalinity and a pH value of 12; it has less corrosion on the workpiece, less damage to the surface state of the workpiece, and a higher efficiency in removing grease; use hydrochloric acid with a concentration of 40% for corrosion, and add ...

Embodiment 2

[0031] Such as figure 1 As shown, a kind of door leaf production process is provided, comprising the following steps:

[0032] Step 1: Cut the board, cut the board out of the pre-designed shape;

[0033] Step 2: Punching, after cutting the plate, use the punching device to punch the plate;

[0034] Step 3: Bending, using a bending machine to bend the punched plate;

[0035] Step 4: Pickling and phosphating the bent plate to remove grease, rust, and surface adjustment;

[0036] When removing grease, treat it in a low-alkaline cleaning agent. The low-alkaline cleaning agent is composed of inorganic low-alkaline additives, surfactants, and defoamers. The treatment temperature is 20 degrees and the treatment time is 4 minutes. Its alkalinity is low, and its pH value is 9; it has less corrosion on the workpiece, less damage to the surface state of the workpiece, and higher efficiency in removing grease; use hydrochloric acid with a concentration of 12% for corrosion, and add an ...

Embodiment 3

[0039] Such as figure 1 As shown, a kind of door leaf production process is provided, comprising the following steps:

[0040] Step 1: Cut the board, cut the board out of the pre-designed shape;

[0041] Step 2: Punching, after cutting the plate, use the punching device to punch the plate;

[0042] Step 3: Bending, using a bending machine to bend the punched plate;

[0043] Step 4: Pickling and phosphating the bent plate to remove grease, rust, and surface adjustment;

[0044] When removing grease, treat it in a low-alkaline cleaning agent. The low-alkaline cleaning agent is composed of inorganic low-alkaline additives, surfactants, and defoamers. The treatment temperature is 35 degrees and the treatment time is 25 minutes. It has low alkalinity and a pH value of 10; it has less corrosion on the workpiece, less damage to the surface state of the workpiece, and a higher efficiency in removing grease; use hydrochloric acid with a concentration of 25% for corrosion, and add an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com