A kind of composition for iron and steel phosphating and preparation method thereof

A composition and steel technology, applied in the direction of metal material coating process, etc., can solve the problems of long phosphating time, slow phosphating speed of steel materials, and insufficient color and luster, and achieve low cost of raw materials and fast phosphating speed. , bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

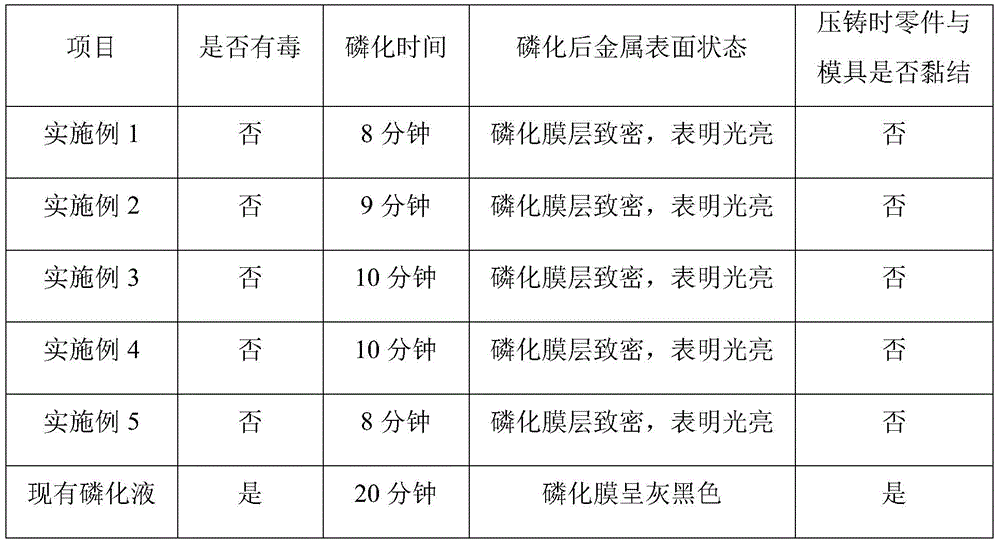

Examples

Embodiment 1

[0028] A composition for iron and steel phosphating consists of the following components in parts by mass: 2 parts of sodium nitrate, 2 parts of sodium citrate, 15 parts of manganese dihydrogen manganese phosphate, 5 parts of magnesium oxide, 10 parts of nickel nitrate, 2 parts of copper sulfate, 1 part of sulfosalicylic acid, 2 parts of polyethylene glycol, 500 parts of deionized water.

[0029] A preparation method for a composition for iron and steel phosphating, comprising the following steps:

[0030] a. Weigh the components according to the number of parts by mass, divide the deionized water into two parts, and then add sodium nitrate, copper sulfate, manganese dihydrogen manganese phosphate, nickel nitrate and magnesium oxide to one part of the deionized water , stir for 3 minutes until completely dissolved, and control the stirring speed to 40 rpm;

[0031] b. Add sodium citrate, sulfosalicylic acid and polyethylene glycol to another part of deionized water, stir for ...

Embodiment 2

[0034] A composition for iron and steel phosphating consists of the following components in parts by mass: 6 parts of sodium nitrate, 4 parts of sodium citrate, 25 parts of ferric manganese phosphate, 10 parts of magnesium oxide, 20 parts of nickel nitrate, 5 parts of copper sulfate, 3 parts of sulfosalicylic acid, 5 parts of polyethylene glycol, 900 parts of deionized water.

[0035] A preparation method for a composition for iron and steel phosphating, comprising the following steps:

[0036] a. Weigh the components according to the number of parts by mass, divide the deionized water into two parts, and then add sodium nitrate, copper sulfate, manganese dihydrogen manganese phosphate, nickel nitrate and magnesium oxide to one part of the deionized water , stir for 4 minutes until completely dissolved, and control the stirring speed to 45 rpm;

[0037] b. Add sodium citrate, sulfosalicylic acid and polyethylene glycol to another part of deionized water, stir for 6 minutes un...

Embodiment 3

[0040] A composition for iron and steel phosphating consists of the following components in parts by mass: 3 parts of sodium nitrate, 2 parts of sodium citrate, 18 parts of manganese dihydrogen manganese phosphate, 6 parts of magnesium oxide, 12 parts of nickel nitrate, 3 parts of copper sulfate, 2 parts of sulfosalicylic acid, 3 parts of polyethylene glycol, 700 parts of deionized water.

[0041] A preparation method for a composition for iron and steel phosphating, comprising the following steps:

[0042] a. Weigh the components according to the number of parts by mass, divide the deionized water into two parts, and then add sodium nitrate, copper sulfate, manganese dihydrogen manganese phosphate, nickel nitrate and magnesium oxide to one part of the deionized water , stir for 5 minutes until completely dissolved, and control the stirring speed to 55 rpm;

[0043] b. Add sodium citrate, sulfosalicylic acid and polyethylene glycol to another part of deionized water, stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| film density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com