Phosphorizing liquid for pretreating high-carbon steel wire before drawing and preparation method of phosphorizing liquid

A technology of high carbon steel wire and phosphating liquid, applied in the field of phosphating liquid, can solve the problems of difficult control, deterioration of phosphating liquid, uneven thickness of phosphating film, etc. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

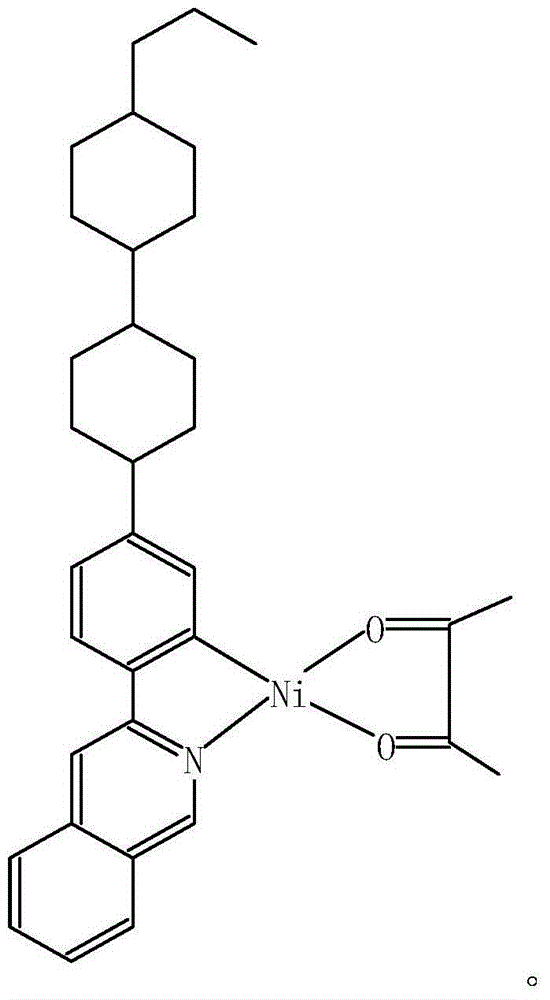

Image

Examples

Embodiment 1

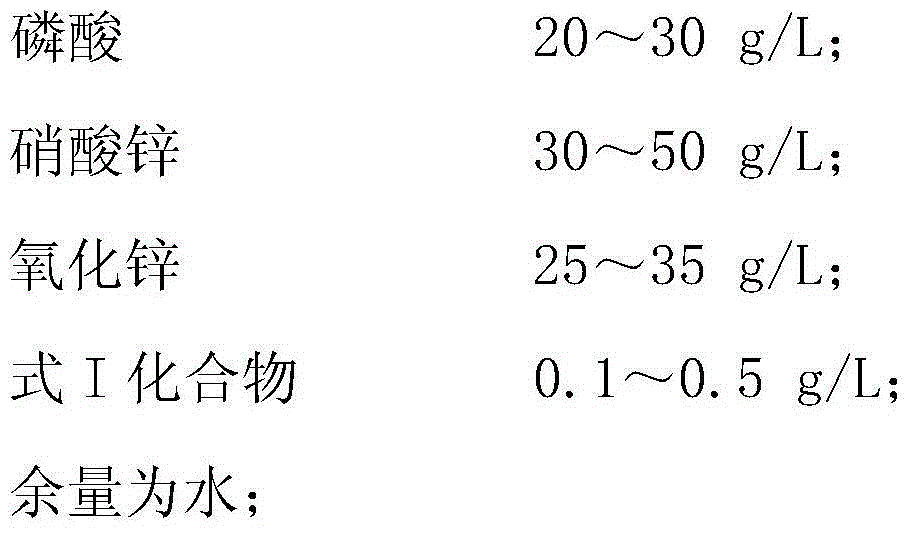

[0026] The phosphating solution of the present invention is made up of following raw materials:

[0027]

[0028] Add zinc oxide into a small amount of water to make a paste, then add phosphoric acid and stir until fully dissolved. Then add zinc nitrate and the compound of formula I, add water to the use height, heat and stir to constant volume. The pH is controlled at 4, and the temperature is controlled at 65°C. The film forming speed of this phosphating solution formula is slow, and the phosphating film is black, thick, and loose, and is suitable for larger steel wires.

Embodiment 2

[0030] The phosphating solution of the present invention is made up of following raw material:

[0031]

[0032] The preparation method is the same as in Example 1, the pH is controlled at 5, and the temperature is controlled at 70°C. This phosphating solution formula has a moderate phosphating and film-forming speed, and the phosphating film is black, moderately thick, and dense, and is suitable for a wide range of steel wire specifications.

Embodiment 3

[0034]

[0035]

[0036] The preparation method is the same as in Example 1, the pH is controlled at 6, and the temperature is also controlled at 75°C. This kind of phosphating solution has a faster phosphating film forming speed, and the phosphating film is gray-black, thinner and dense, and is suitable for steel wires with smaller specifications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com