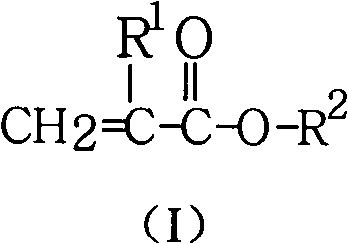

Preparation method for polyethylene glycol mono alkyl ether unsaturated carboxylic ester

A polyethylene glycol monoalkyl ether and unsaturated technology, which is applied in the field of preparation of polyethylene glycol monoalkyl ether unsaturated carboxylic acid esters, can solve the problem that the one-step process route is short, the two-step process route is long, and the Reduce the one-step reaction temperature and other problems to achieve the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 200g of methyl acrylate and the catalyst of 0.8wt% relative to methyl acrylate and drop into ethylene oxide gross weight in the dry reactor with stirring, electric heating jacket and internal water-cooled coil, relative to methyl acrylate and Add 0.5 wt% polymerization inhibitor of ethylene oxide gross weight, and seal the reaction kettle. The autoclave was purged with nitrogen and then evacuated three times. Start stirring, and heat to 80°C and maintain this temperature, slowly pass in 23.23 moles of ethylene oxide (that is, the molar ratio of methyl acrylate to EO is 1:10), and maintain the temperature by controlling the feed rate of ethylene oxide. The reaction pressure was 0.9 MPa, and it took 6 hours to feed the above-mentioned amount of ethylene oxide (ie, the reaction time was 6 hours). Aging at the reaction temperature for 1 hour, then cooling to 60° C. and vacuum treatment for 10 minutes under a pressure of -0.07 MPa, stopping stirring, and opening the rea...

Embodiment 2

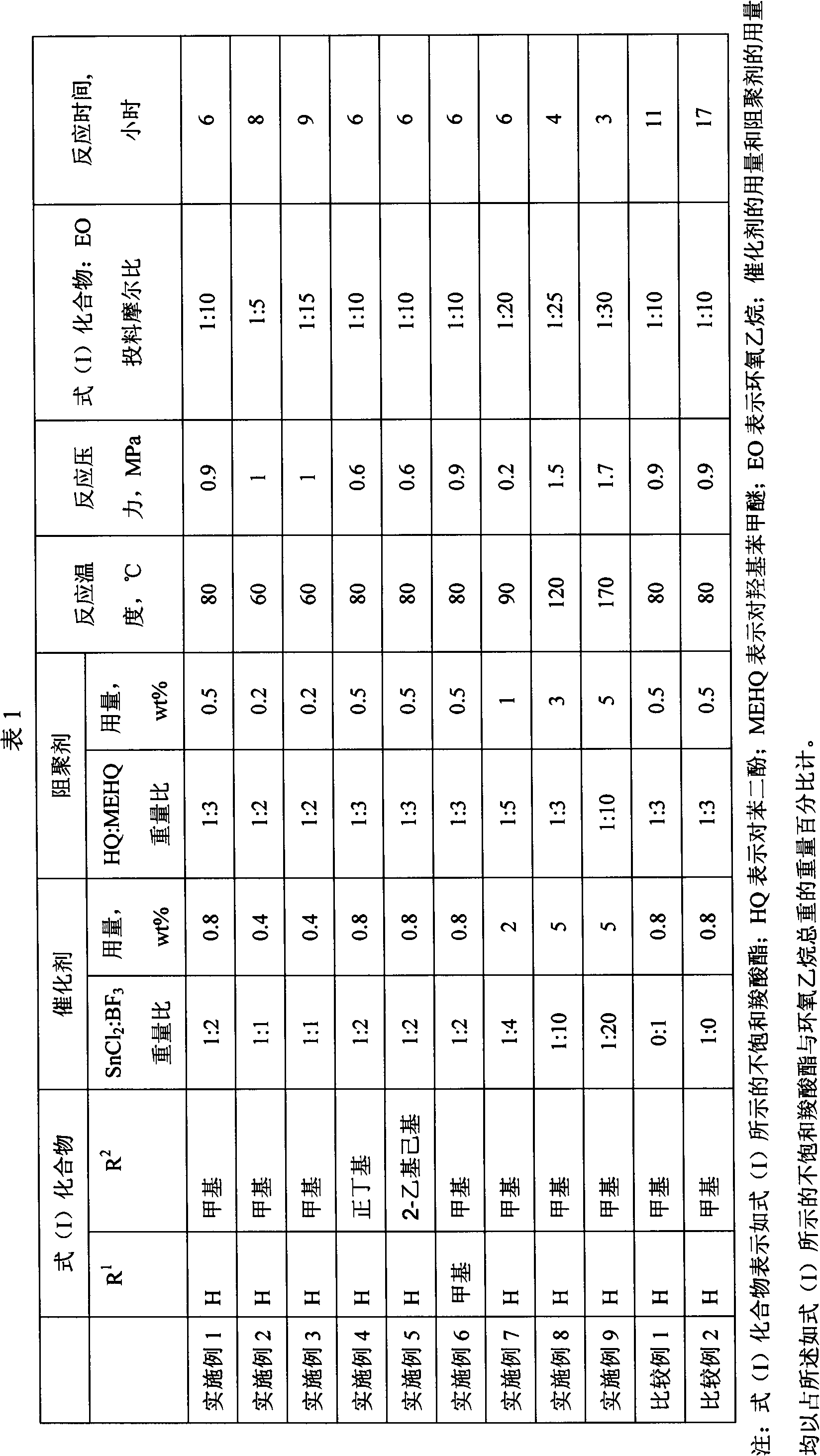

[0024] [Example 2] to [Example 9] and [Comparative Example 1] and [Comparative Example 2]

[0025] Except the unsaturated carboxylate kind shown in formula (I), the composition of catalyzer, the consumption of catalyzer, the composition of polymerization inhibitor, polymerization inhibitor consumption, temperature of reaction, reaction pressure, pass into EO mole number (or in formula ( 1) Shown unsaturated carboxylic acid ester and EO feed molar ratio meter) and reaction time have change, other operating conditions are all identical with embodiment 1.

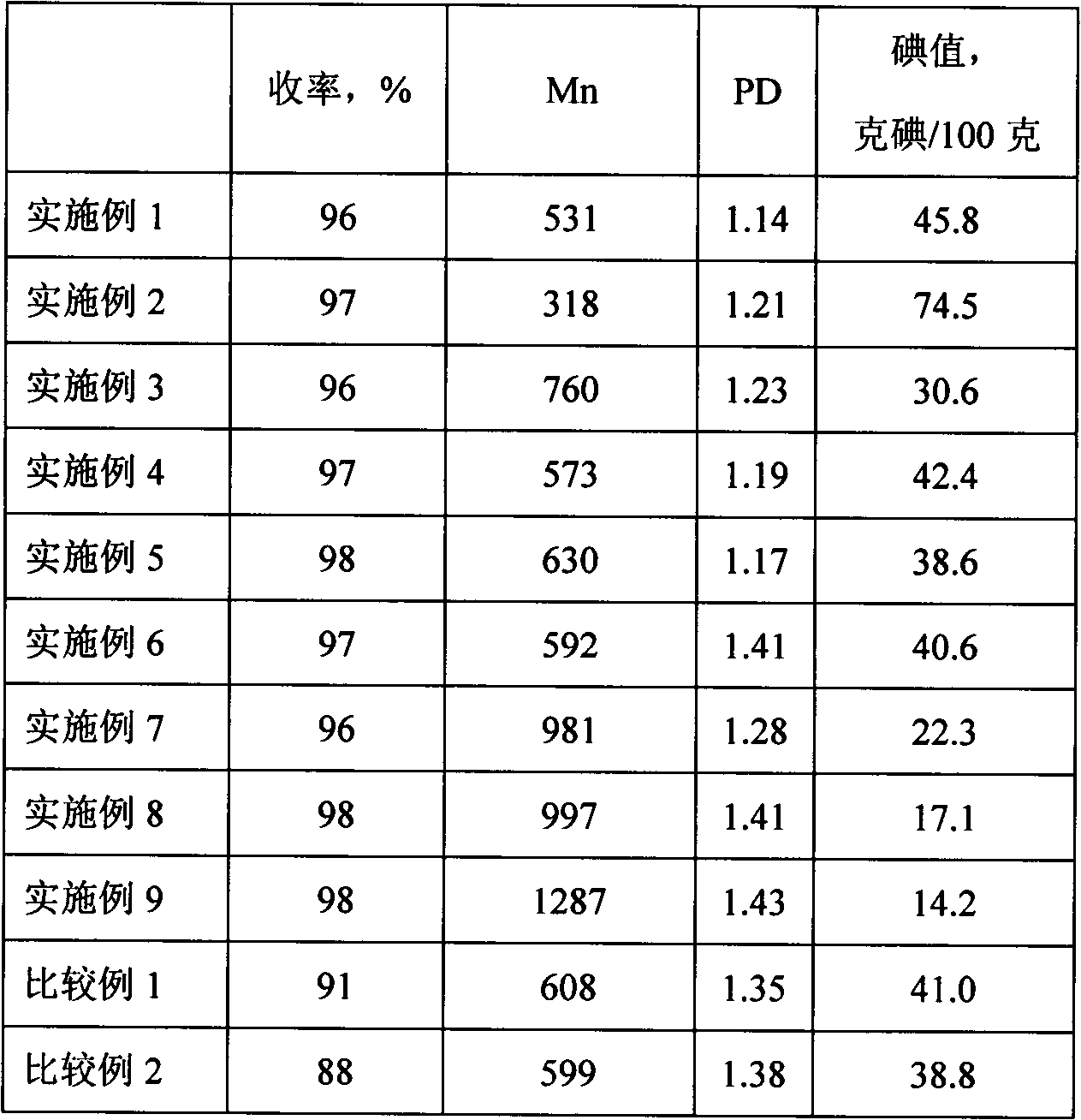

[0026] Important preparation conditions are listed in Table 1 for ease of comparison, and the yield of product, number average molecular weight Mn, dispersion coefficient PD and iodine value are listed in Table 2.

[0027] From Comparative Example 1 and Comparative Example 2 compared with Example 1, it can be seen that the use of SnCl 2 or BF 3 The reaction time of the single-component catalyst is significantly longer than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com