Addition type liquid silicone rubber bonding accelerant and preparation method and application thereof

A technology of adhesion promoter and liquid silicone rubber, which is applied in the field of addition-type liquid silicone rubber adhesion promoter and its preparation, can solve unfavorable processing and molding of addition-type liquid silicone rubber, high viscosity of addition-type liquid silicone rubber, and catalyst poisoning Silicone rubber mechanics and other issues, to achieve the effect of cheap raw materials, improve mechanical properties, and improve bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

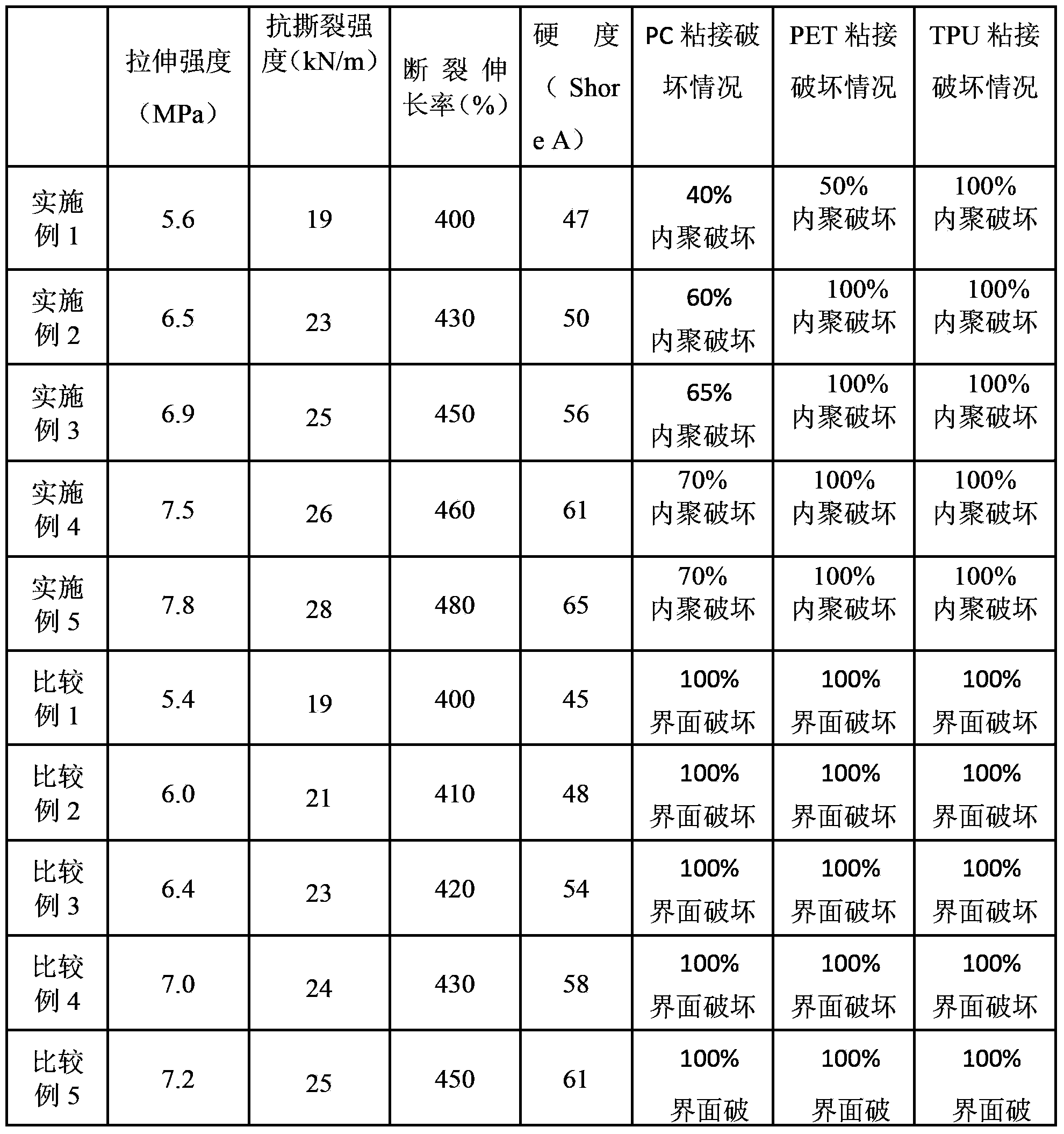

Examples

Embodiment 1

[0025] 1. Synthesis of adhesion promoter

[0026] Mix 7.53g of 1,6-hexanediol diacrylate and 0.02g of isopropanol solution of chloroplatinic acid with a platinum concentration of 2200ppm in a flask, preheat at 60°C for 30min, and set aside.

[0027] Add 20g of hydrogen-containing silicone oil with a mass fraction of 0.5% hydrogen and a viscosity of 600mPa.s, 40g of toluene and 0.1g of p-hydroxyanisole into a four-necked flask with a thermometer and a condensing reflux tube, and heat up while stirring. When the temperature in the four-necked flask reached 60°C, the preheated mixture of 1,6-hexanediol diacrylate and chloroplatinic acid isopropanol solution was added dropwise to the four-necked flask for 1 hour. After the dropwise addition, the reaction temperature was controlled at 80° C. for 2 h. Then add 5g of activated carbon into the four-necked flask, and the adsorption time is 1h. Finally, the reacted solution was subjected to suction filtration and distillation to obtai...

Embodiment 2

[0043] 1. Synthesis of adhesion promoter

[0044] 18.80 g of 1,6-hexanediol diacrylate, 4.16 g of isobornyl acrylate and 0.02 g of platinum(0)-1,3-divinyl-1,1,3,3- The tetramethyldisiloxane complex was mixed in the flask and preheated at 50° C. for 30 minutes, and set aside.

[0045] Add 20g of hydrogen-containing silicone oil with a mass fraction of 1.6% hydrogen and a viscosity of 80mPa.s, 80g of toluene and 0.2g of p-hydroxyanisole into a four-necked flask with a thermometer and a condensing reflux tube, and heat up while stirring. When the temperature in the four-necked flask reached 60°C, the preheated 1,6‐hexanediol diacrylate, isobornyl acrylate and platinum (0)‐1,3‐divinyl‐1,1,3 , The mixture of 3-tetramethyldisiloxane complex was added dropwise to a four-necked flask, and the dropping time was 2h. After the dropwise addition, the reaction temperature was controlled at 80° C. for 3 h. Then add 5g of activated carbon into the four-necked flask, and the adsorption tim...

Embodiment 3

[0052] 1. Synthesis of adhesion promoter

[0053] Mix 7.69g of 1,5-pentanediol diacrylate, 5.14g of glycidyl methacrylate and 0.02g of tetrahydrofuran solution of chloroplatinic acid with a platinum concentration of 2000ppm in a flask, preheat at 50°C for 40min, and set aside .

[0054] Add 20g of hydrogen-containing silicone oil with a mass fraction of 0.68% hydrogen and a viscosity of 50mPa.s, 60g of toluene and 0.10g of p-hydroxyanisole into a four-necked flask with a thermometer and a condensing reflux tube, and heat up while stirring. When the temperature in the four-necked flask reached 60°C, the mixture of preheated 1,5-pentanediol diacrylate, glycidyl methacrylate and chloroplatinic acid tetrahydrofuran solution was added dropwise to the four-necked flask, and Adding time is 2h. After the dropwise addition, the reaction temperature was controlled at 80° C. for 3 h. Then add 5g of activated carbon into the four-necked flask, and the adsorption time is 0.5h. Finally,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com