Patents

Literature

62results about How to "Not poisoned" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Addition type liquid silicone rubber bonding accelerant and preparation method and application thereof

The invention discloses an addition type liquid silicone rubber bonding accelerant and a preparation method and application thereof. The preparation method comprises the steps as follows: mixing an acrylic ester compound and a platinum catalyst solution, and preheating the mixed solution for 20-60 minutes at the temperature of 30-60 DEG C for later use; adding silicon hydrogen bond, hydrogen-containing silicone oil, methylbenzene and para-hydroxybenzaldehyde into a reactor; stirring while heating; when the temperature in the reactor achieves 30-80 DEG C, dripping the mixture of the acrylic ester compound and the platinum catalyst which are primarily heated to 30-60 DEG C into the reactor, for 0.5-3 hours; after dripping, controlling the reaction temperature within 50-90 DEG C and reacting for 0.5-4 hours; adding activated carbon for adsorption, and then performing suction filtering and rotary evaporation to the solution after reaction so as to obtain the bonding accelerant. The bonding accelerant prepared through the method can remarkably improve the adhesive property of the addition type liquid silicon rubber, the preparation process is simple and convenient, the raw materials are cheap and easy to obtain, and the industrialized production is facilitated.

Owner:东莞市贝特利新材料有限公司

SCR denitration catalyst as well as preparation method and application thereof

ActiveCN102658172AHigh activityGood choicePhysical/chemical process catalystsDispersed particle separationAlkaline earth metalRare earth

The invention discloses an SCR (Selective Catalytic Reduction) denitration catalyst as well as a preparation method and the application of the catalyst, wherein, sulfated zirconia is taken as a carrier, the surface of the carrier is loaded with rare-earth metal oxides that are taken as active ingredients and is loaded with transition metal oxides that are taken as a cocatalyst. The preparation method of the catalyst comprises the steps as follows: (1), zirconia is soaked in sulfuric acid solution, and the sulfated zirconia carrier is obtained after drying and burning are carried out; and (2), the zirconia carrier is in contact with ionic or complexing metal to be loaded proportionally in any sequence, adsorption is performed, and then the SCR denitration catalyst is obtained after drying and burning are carried out. The SCR denitration catalyst achieves excellent alkali metal and alkaline earth metal poisoning resistance when being used for the flue gas denitration, and is especially suitable for the flue gas denitration when the content of alkali metal or alkaline earth metal in flue gas is higher; the denitration efficiency of the SCR denitration catalyst stabilizes at more than 95 percent under a certain condition; and the denitration efficiency can still stabilize at more than 90 percent after being soaked in alkali metal solution or alkaline earth metal solution.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Deep deoxidizing apparatus and application thereof

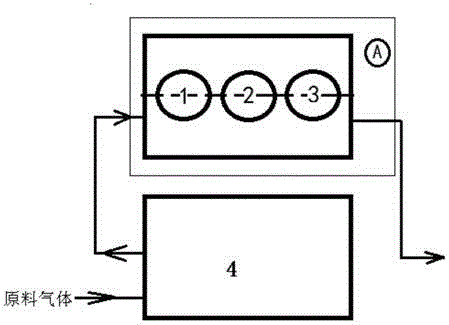

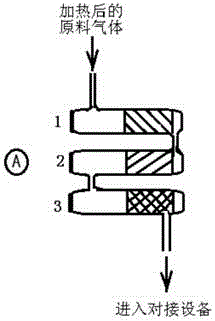

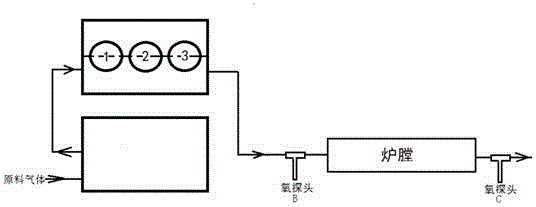

The invention relates to a deep deoxidizing apparatus and an application thereof, and belongs to the technical field of chemical reaction deoxidization. The deep deoxidizing apparatus designed by the invention comprises a gas heating device (4), a No.1 deoxidizing channel (1), a No.2 deoxidizing channel (2) and a No.3 deoxidizing channel (3) which are sequentially communicated, wherein a No.1 deoxidizing agent is contained inside the No.1 deoxidizing passage (1), and the No.1 deoxidizing agent is selected from one of elemental metallic copper and copper-based alloy; a No.2 deoxidizing agent is contained inside the No.2 deoxidizing channel (2), and the No.2 deoxidizing agent is selected from one of elemental metallic titanium, sponge titanium and titanium-based alloy; a No.3 deoxidizing agent is contained inside the No.3 deoxidizing passage (3), and the No.3 deoxidizing agent is selected from one of elemental magnesium and magnesium-based alloy. The apparatus disclosed by the invention, when applied to deoxidizing treatment on Ar gas which is 99.999% in purity, can achieve a deoxidizing precision of 10-21ppm. The apparatus designed by the invention can carry out efficient deep deoxidization under normal pressure, and has the advantages of simple equipment, recycling use of the deoxidizing agents and the like.

Owner:CENT SOUTH UNIV

Addition type liquid silicone rubber tackifier, as well as preparation method and application thereof

InactiveCN106279700AImprove bonding performanceGood mold releaseNon-macromolecular adhesive additivesMacromolecular adhesive additivesActivated carbonHydroxybenzoate Ethers

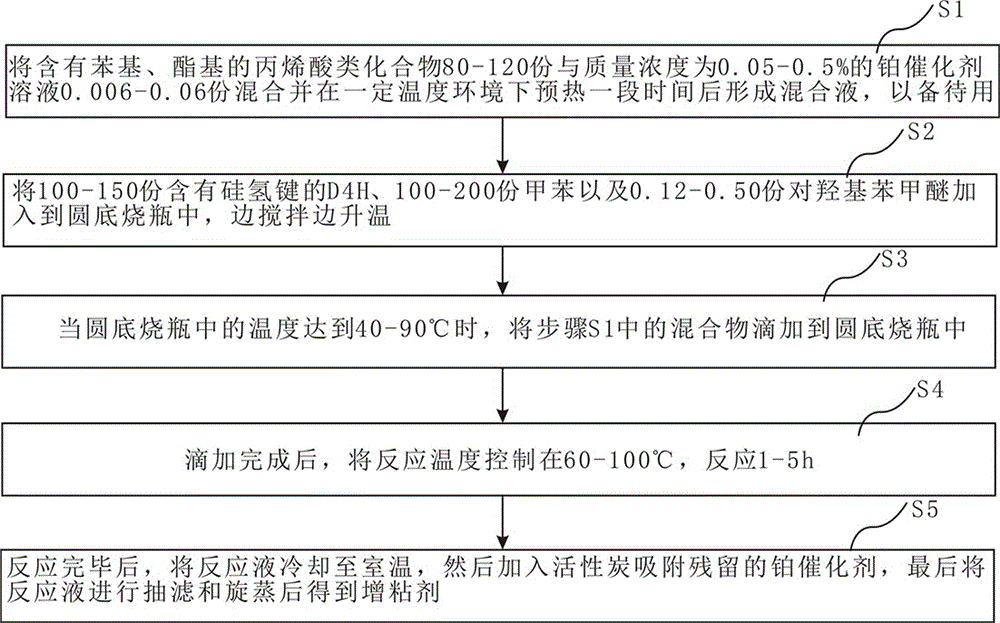

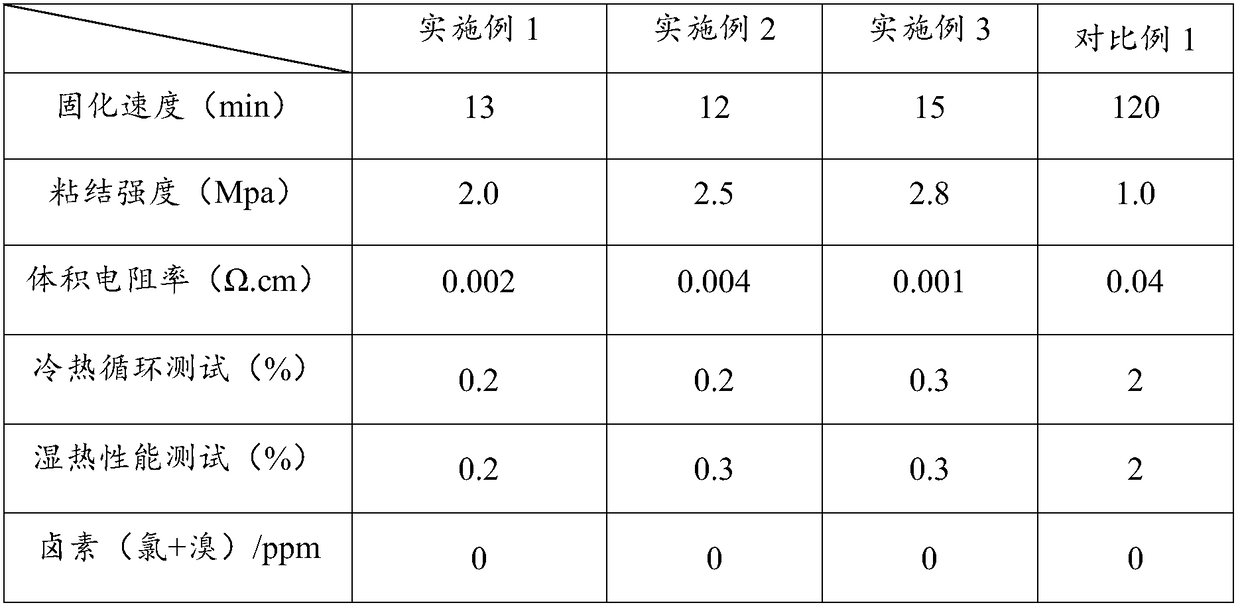

The invention discloses an addition type liquid silicone rubber tackifier, as well as a preparation method and application thereof. The preparation method comprises the following steps of step 1, mixing 80-120 parts of an acrylic compound containing phenyl groups and ester groups with 0.006-0.06 part of a platinum catalyst solution of which the mass concentration is 0.05-0.5% to obtain a mixture, and preheating the mixture at certain temperature environment for some time so as to obtain mixed liquor for standby application; step 2, adding 100-150 parts of D4H containing silicon-hydrogen bonds, 100-200 parts of toluene and 0.12-0.50 part of p-hydroxyanisole to a round-bottomed flask, and raising temperature while stirring; step 3, when the temperature in the round-bottomed flask reaches to 40-90 DEG C, dropwise adding the mixture in the step 1 to the round-bottomed flask; step 4, after the mixture is dropwise added, controlling the reaction temperature to 60-100 DEG C, and performing a reaction for 1-5h; and step 5, after the reaction is completed, cooling reaction fluid to room temperature, then adding activated carbon for adsorbing residual platinum catalysts, and finally performing sucking filtration and rotary evaporation on the reaction fluid so as to obtain the tackifier. According to the addition type liquid silicone rubber tackifier, as well as the preparation method and application thereof disclosed by the invention, a small quantity of the tackifiers are added to shaping liquid silicone rubber, so that the bonding failure between the shaping liquid silicone rubber and PC plastic cement reaches to 100% cohesive failure.

Owner:岳胜武

High performance no-contraction cement base grouting material and its preparing method

The high-performance no-contraction cement-base grouting material consists of portland cement, sulphoaluminate clinker, bentonite, sodium methyl naphthalenesulfonate condensate, defoaming agent, quartzite, etc. in certain proportion. The grouting material has controllable solidification time, excellent flowability, excellent grouting performance, relatively high volume stability and no contraction. The present invention may be used widely in the repair and construction of various concrete engineering.

Owner:TONGJI UNIV

Method for preparing 3-(methacryloxy)propyltrimethoxysilane

ActiveCN101121724AHigh catalytic efficiencyLow costGroup 4/14 element organic compoundsSilanesDissolution

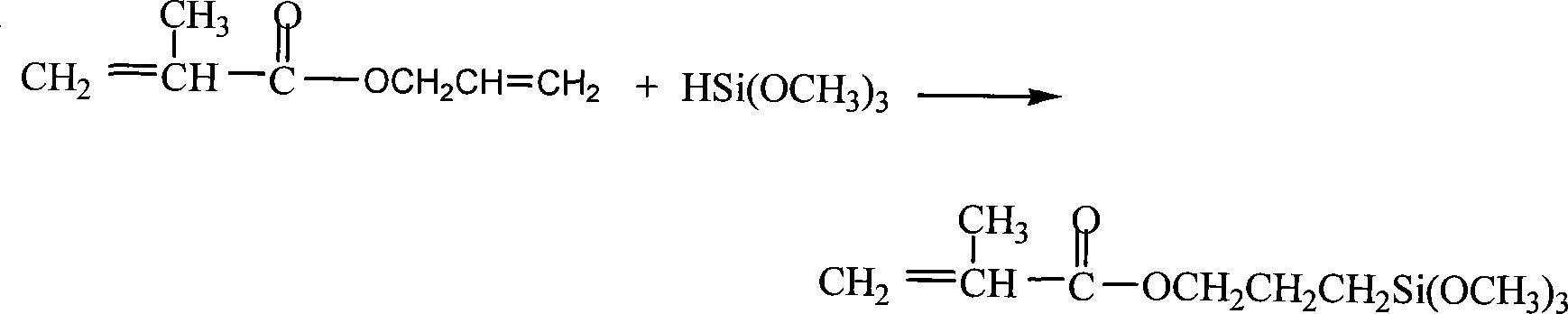

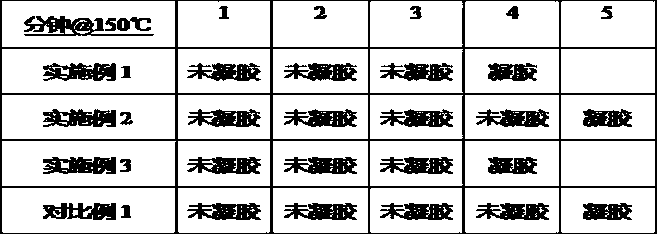

The invention discloses a preparation method of the 3-(methacryloyl oxygen) propyl tri-methoxy silane. The steps are: first the platinum chloride acid, isopropanol and the compound A are used as the raw materials; the platinum chloride acid is added into the isopropyl alcohol; after the dissolution, the compound A is added and then to be heated; secondly, the polymerization-preventing reagent phenothiazine and ZJ-701 are added into the tri-methoxy silane to dissolve the raw material X; thirdly, the polymerization-preventing reagent N, N'-drophenyl-p-phenylenediamine are added in the methacrylate allylic ester to dissolve the raw material Y; fourthly, the polymerization-preventing reagent ZJ-701 and ZJ-101 are added in the reaction materials after the reaction between the raw materials and the catalysts to dissolve to get the 3-(methacryloyl oxygen) propyl tri-methoxy silane. The invention is of the simple preparation, the high efficiency, the little consumption, the strong selectivity, and the high collection rate of the products; the polymerization-preventing effects of the polymerization-preventing technology are good; the polymerization-preventing reagents are not easy to be gelated; the consumption is little; the polymerization-preventing reagents are easily separated from the products; the products are easy to be decolorized, good in quality, and have no harm to the catalyst.

Owner:湖北武大有机硅新材料股份有限公司

Self-spraying self-adhesive type environment-friendly silica gel adhesive and preparation method thereof

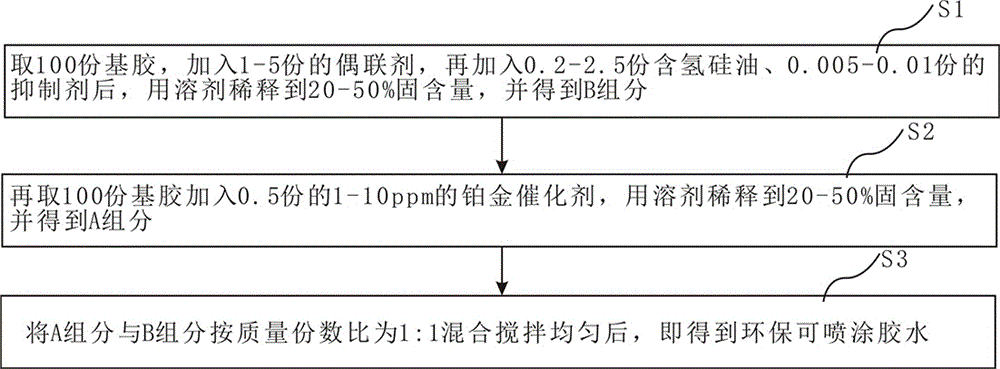

The invention discloses a self-spraying self-adhesive type environment-friendly silica gel adhesive and a preparation method thereof. The preparation method comprises the following steps that 100 parts of a base adhesive is taken, 1-5 parts of a coupling agent is added, then, after 0.2-2.5 parts of containing hydrogen silicone oil and 0.005-0.01 part of an inhibitor are added, a solvent is used for dilution till the solid content is 20-50%, and a component B is obtained; 100 parts of the base adhesive is taken, 0.5 part of a 1-10 ppm platinum catalyst is added, a solvent is used for dilution till the solid content is 20-50%, and a component A is obtained; after the component A and the component B are mixed and stirred on the basis of the mass ratio being 1:1 to be uniform, the environment-friendly silica gel adhesive capable of being sprayed is obtained. The adhesive coats glass and ceramic, good adhesion can be achieved, silica gel cohesive failure can be achieved, and the solvent is environmentally friendly and free of odor. The adhesive coats the glass ceramic, so that the good adhesion can be achieved, and adhesive failure will not occur after water boiling is performed for 2 h. The prepared adhesive can be well adhered to the glass ceramic, the obtained silica gel is good in strength, good in transparency and easy to operate, and the adhered material obtained after spraying is resistant to boiling.

Owner:岳胜武

Thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst and preparation method thereof

ActiveCN110354843ALarge specific surface areaImprove denitrification activityGas treatmentHeterogenous catalyst chemical elementsChromium trioxideSilicon dioxide

The embodiment provides a thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst. A catalyst carrier is a titanium dioxide-coated silicon dioxide composite nanotube, an active component is vanadium pentoxide, and a catalytic assistant is molybdenum trioxide and chromium trioxide. The thin-wall honeycomb SCR denitration catalyst with low-temperature sulfur resistance performance is prepared by adopting an extrusion molding process. The catalyst has good low-temperature activity and sulfur poisoning resistance, can solve the problems of low activity and sulfur poisoning of the catalyst in low-temperature flue gas, and is suitable for low-temperature sulfur-containing flue gas; by adding various inorganic and organic forming additives and optimizing the drying androasting processes, the wall thickness of the catalyst is reduced on the basis of maintaining the mechanical strength of the catalyst, the sulfur poisoning resistance of the catalyst is improved, theproduction cost is reduced, and the thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst has good economic benefits. The embodiment also provides a preparation method ofthe thin-wall honeycomb type low-temperature sulfur-resistant SCR denitration catalyst.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Automobile gasoline composite modifying agent

ActiveCN103194284ANot poisonedNo carbon depositionLiquid carbonaceous fuelsFuel additivesAntioxidantSolvent

The invention relates to an automobile gasoline composite modifying agent. The raw material of the modifying agent is prepared from the following components in percentage by weight: 25-50% of an octane value promoter, 30-50% of a combustion improver and 20-25% of a latent solvent, wherein the octane value promoter comprises the following components in percentage by weight: 20-45% of sec-butyl acetate, 30-40% of diisopropyl ether, 5-10% of absolute ethyl alcohol and 20-30% of methyl tert-butyl ether; the combustion improver comprises the following components in percentage by weight: 10-20% of cyclopentane, 47-50% of mixed light arene, 30-40% of alkylate and 3-6% of 1# jet fuel; and the latent solvent comprises the following components in percentage by weight: 10-30% of acetone, 25-30% of dimethoxy ethane, 20-25% of industrial isobutyl alcohol, 22.5-28% of industrial isopropyl alcohol, 1-4% of trinitromethane, 1-2% of glycol ethylene ether, 0.1-0.2% of a clearing agent polyisobutene succinimide, 0.2-0.4% of a metal deactivator T1201 and 0.2-0.4% of an antioxidant. By adopting the automobile gasoline composite modifying agent, a three-way catalyst of an organic ashless exhaust system cannot be poisoned, a fuel spray nozzle and a cylinder exhaust valve cannot be abraded, and carbon deposition and abrasive particles cannot be generated in a machine body.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

Single-component conductive silica gel for solar packaging and preparation method thereof

ActiveCN109401724ANot poisonedFast curingNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolventSilica gel

The invention relates to single-component conductive silica gel for solar packaging and a preparation method thereof. The single-component conductive silica gel is prepared from the following components in parts by weight: 55 to 80 parts of modified silver powder, 10 to 20 parts of addition type liquid silicone oil, 0.02 to 1 part of a coupling agent, 2 to 10 parts of a reinforcing agent, 0.5 to 4parts of a crosslinking agent, 2 to 5 parts of a special active diluting agent, 0.0002 to 0.02 part of a platinum catalyst and 5 to 20 parts of a solvent. The conductive silica gel provided by the invention can be rapidly cured at middle and low temperature and has low viscosity, and can meet the technical requirements of flow-line rapid curing of laminated sheets; the adding amount of silver islow so that the cost is relatively low and the single-component conductive silica gel can be applied to solar imbrication subassemblies on a large scale; furthermore, the single-component conductive silica gel has the advantages of no toxicity and environment protection, rapid heat dissipation, high conductivity and good anti-ageing performance and can meet the requirements of ultrahigh power, lowhot spot effect and outdoor 25-year service life of the imbrication subassemblies.

Owner:YANTAI DARBOND TECH

Cultivation method for selenium-rich malting barley

InactiveCN103988646AImprove qualityAvoid One-Time SupplementsFertilising methodsSeed coating/dressingHordeum vulgareMonopotassium phosphate

The invention relates to a cultivation method for selenium-rich malting barley, in particular to a safe, reliable, standard, stable and high-yield cultivation method for selenium-rich malting barley. The method comprises the first step of selecting 'Ganpi No.5' as seeds for broadcast sowing and placing the seeds in a mash for seed dressing, wherein the mash is formed by adding a sodium selenite solution with the concentration being 0.02 percent-0.1 percent into sandy loam or loam, the second step of selecting a plot with sandy loam or loam and applying selenium-rich fertilizers with the standard being 5 kg-15 kg per mu, the third step of applying composite fertilizers added with sodium selenite to the plot for top dressing when the malting barley grows to 6 cm-10 cm after seedling emergence, the fourth step of applying leaf fertilizers one time when malting barley seedlings grow to the late growth stage, wherein sprayed fertilizers comprise monopotassium phosphate and sodium selenite, the volume ratio of the monopotassium phosphate to the sodium selenite is one to one, the concentration of the monopotassium phosphate is 0.1 percent-0.2 percent, and the concentration of the sodium selenite is 0.02 percent-0.1 percent, and the fifth step of harvesting the malting barley after the malting barley is ripe and fully sunning the harvested malting barley to obtain finished selenium-rich malting barley.

Owner:张斌

Cellular SCR denitration catalyst unit hardening liquid and use method thereof

ActiveCN104128210AEvenly distributedImprove wear resistanceCatalyst protectionCatalyst activation/preparationOrganic acidOxalate

The invention discloses a cellular SCR denitration catalyst unit hardening liquid. The cellular SCR denitration catalyst unit hardening liquid comprises, by weight, 20-40 parts of water, 10 parts of aluminum sulfate, and a proper amount of an organic acid, wherein the organic acid is oxalic acid or citric acid, and a molar ratio of the organic acid to aluminum sulfate is 4:1-1:4. The invention also discloses a use method of the cellular SCR denitration catalyst unit hardening liquid. The organic acid and aluminum sulfate are adopted as a hardening liquid and can form a complex, and the complex is uniformly distributed in a catalyst, improves the anti-wear strength of the catalyst, reduces the wear rate by 30-80%, avoids the high temperature and high dust influences of smoke gas, avoids the wear and collapse phenomenon and prolongs the life of the catalyst. The hardening liquid forms a layer of compact alumina on the top of the cellular SCR denitration catalyst after calcining, and does not realize catalyst poisoning, so the activity of the catalyst is not influenced.

Owner:ZHEJIANG HAILIANG ENVIRONMENTAL MATERIALS

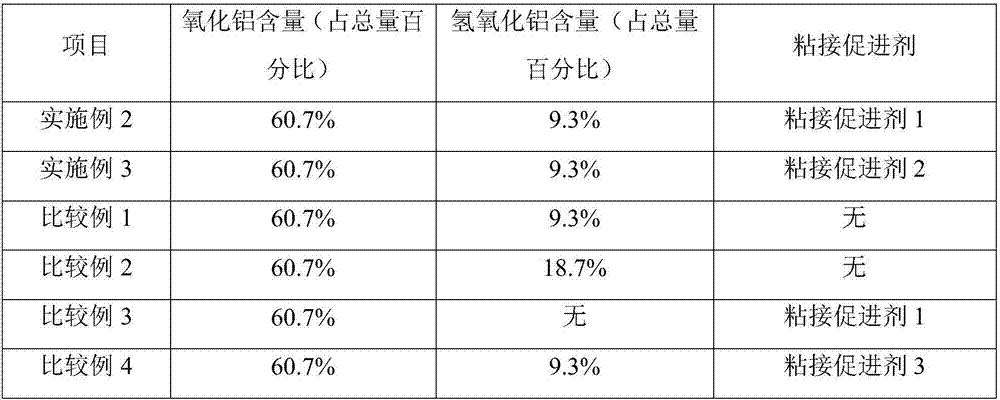

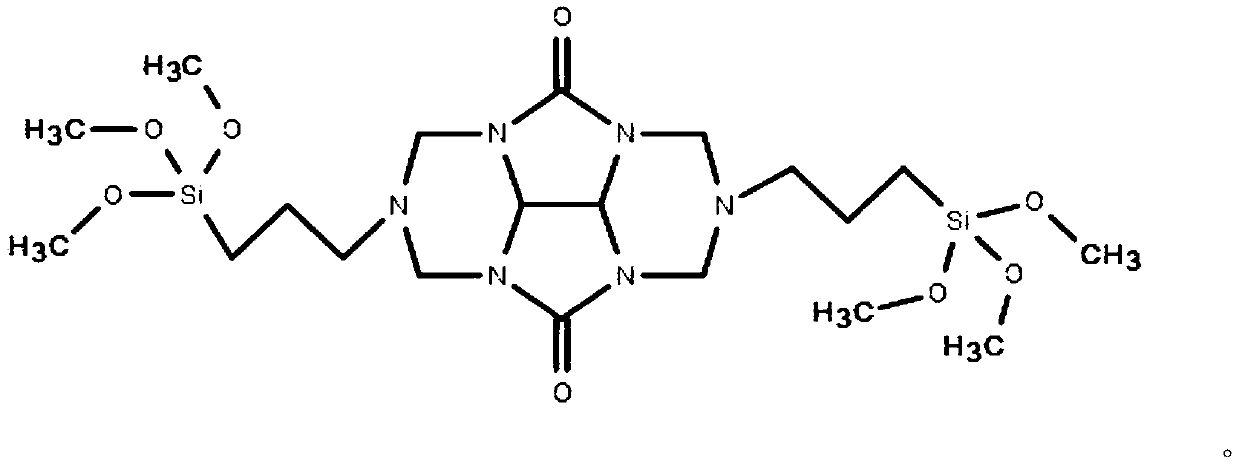

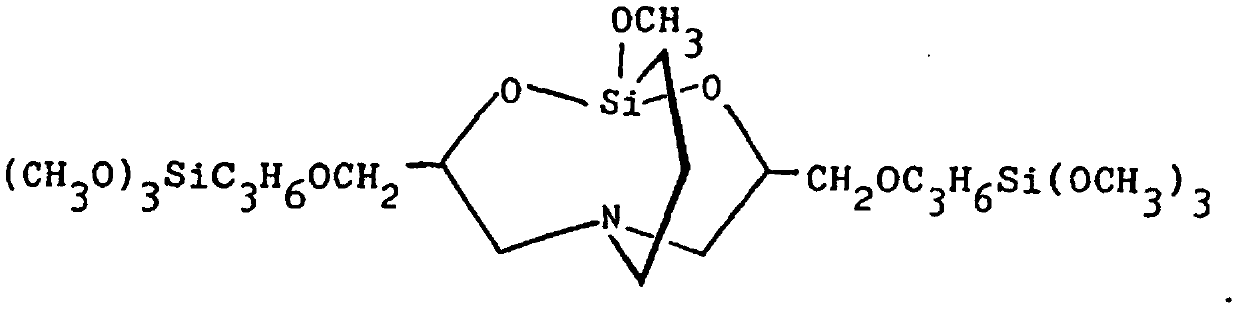

Two-component organosilicon pouring sealant and preparation method thereof

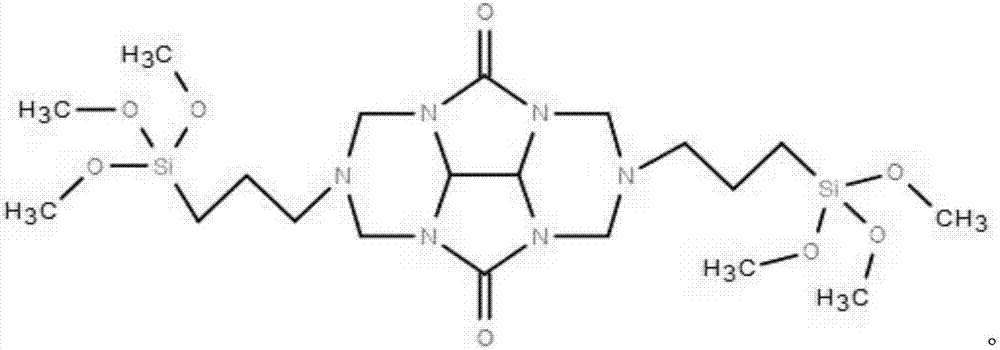

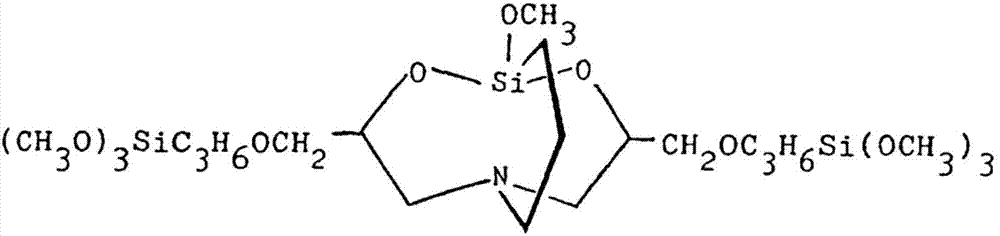

ActiveCN106947428AAdd lessDoes not affect liquidityNon-macromolecular adhesive additivesNitrogenSealant

The invention provides a two-component organosilicon pouring sealant. The two-component organosilicon pouring sealant comprises a component A and a component B with equal mass, wherein the component A comprises 100 parts of a base material, a platinum catalyst with the mass of platinum accounting for 1 to 500 ppm of the mass of the component A, and 1 to 5 parts of an adhesion promoter; the component B comprises 100 parts of a base material, 0.2 to 20 parts of a crosslinking agent and 0.002 to 0.5 part of an inhibitor; and the adhesion promoter is nitrogen heterocycle containing polycyclic siloxane. The invention belongs to the technical field of pouring sealants. The two-component organosilicon pouring sealant provided by the invention has the advantages of good flame-retardant performance, adhesion properties with a substrate, excellent fluidity, no poisoning caused by a platinum catalyst, environmental protection, safety, and easy operation.

Owner:广东皓明有机硅材料有限公司

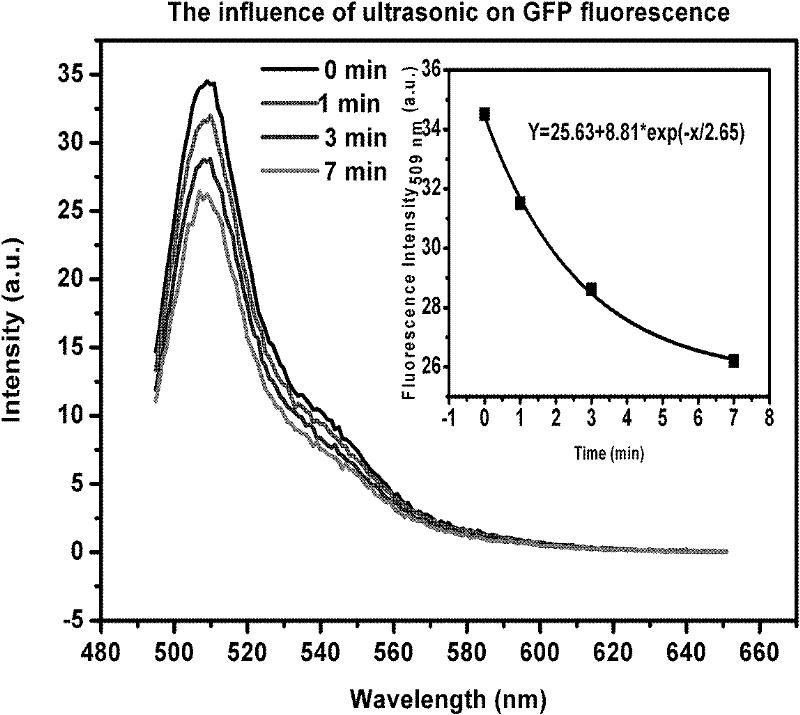

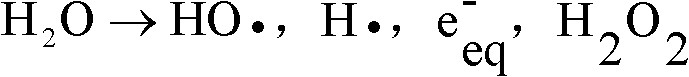

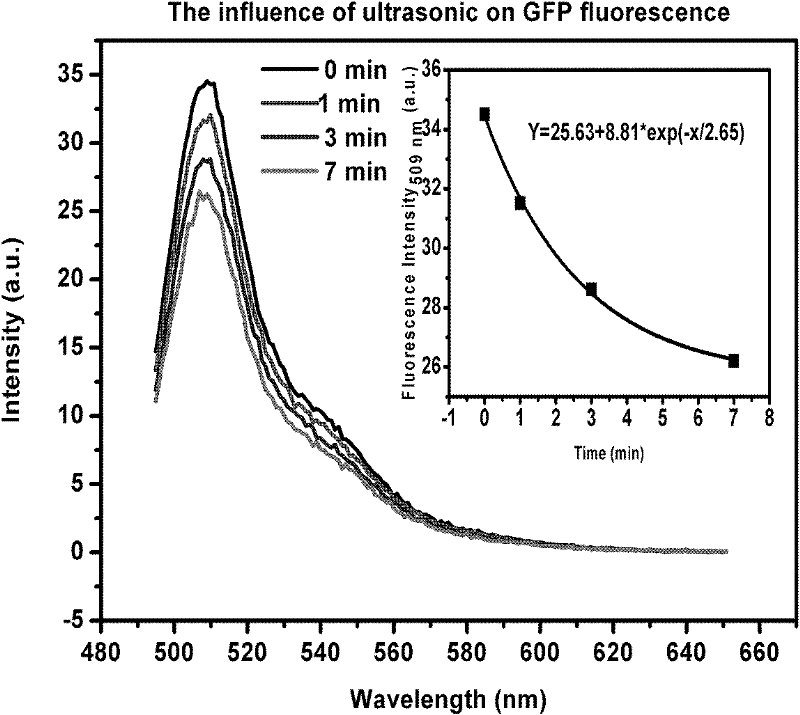

Method for measuring cellular oxidative stress damages under ionizing radiation by using fluorescent protein as fluorescence probe

InactiveCN102230895AEasy to detectNon-toxicFluorescence/phosphorescenceHigh resistanceOrganic solvent

The invention discloses a method for measuring cellular oxidative stress damages under ionizing radiation by using fluorescent protein as a fluorescence probe. The content of free radicals generated in ionizing radiation is quantitatively measured by using the fluorescent protein which is selectively positioned and expressed on a subcellular structure sensitive to the ionizing radiation, so that the damages of the ionizing radiation on the specific positions of a cell are speculated by directly observing the fluorescence intensity change of the protein. By the method, the emitted fluorescence is easy to detect, has high sensitivity, stable fluorescence properties, can normally emit light in a wider pH range, has higher resistance to high temperatures, detergents, salt, organic solvents and most ordinary enzymes, is not toxic to the cell, is not interfered by false positive, makes vector construction convenient and is expressed without specificities of species, tissues and positions.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

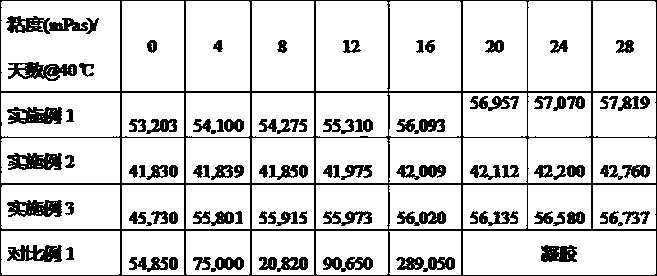

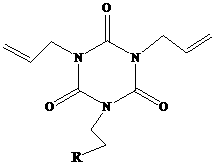

One-component addition type organic silicon electric-conduction adhesive and preparation method thereof

InactiveCN108239520AReduced activityLoss of activityNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveRoom temperature

The invention discloses a one-component addition type organic silicon electric-conduction adhesive and a preparation method thereof. According to the present invention, the trimeric cyanurate group capable of stabilizing the catalyst is introduced into the matrix material of the electric-conduction adhesive through molecular design so as to obtain the one-component addition type organic silicon electric-conduction adhesive capable of being stably stored at the room temperature; and the one-component addition type organic silicon electric-conduction adhesive capable of being stably stored is provided, and has advantages of no requirement of adding of a large amount of stabilizers such as alkynol, good storage stability at room temperature, fast curing, good electrical conductivity and the like.

Owner:苏州瑞力博新材科技有限公司

Magnesium sulfate wet application

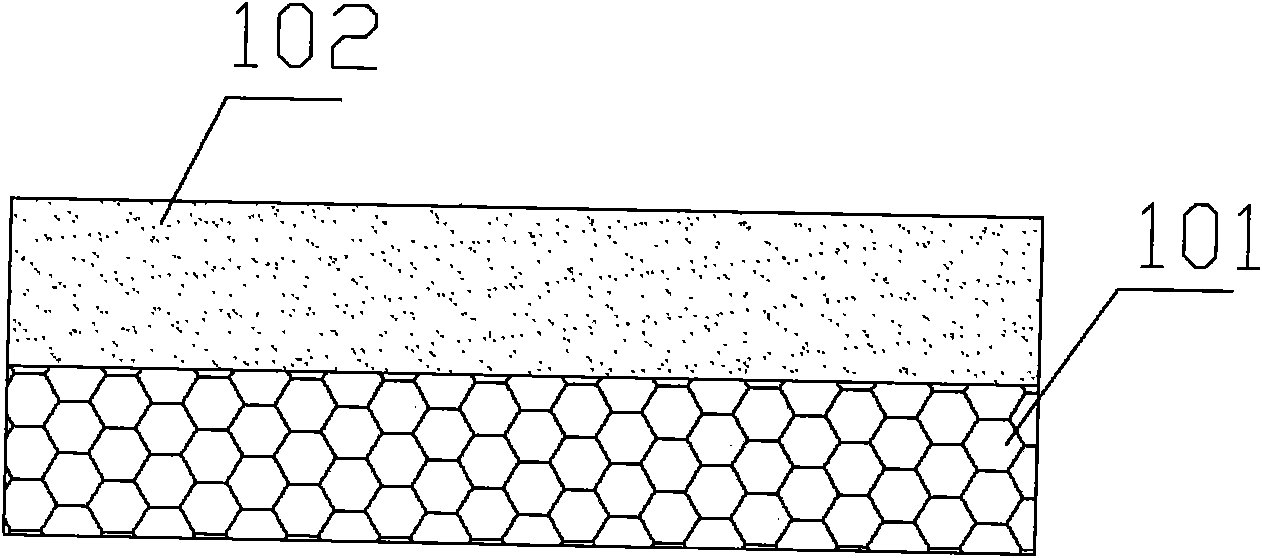

InactiveCN102552222ANo stimulationGood physical propertiesAluminium/calcium/magnesium active ingredientsOil/fats/waxes non-active ingredientsBetaineChemical composition

The invention belongs to the technical field of medical instrument supplies, and in particular relates to a magnesium sulfate wet application. The technical scheme is that the magnesium sulfate wet application comprises a carrier and wet application liquid. The wet application liquid comprises components of magnesium sulfate, deioned water, glycerol and coconut oil amido propyl betaine. The magnesium sulfate wet application adopts a pure sterile formula, contains plant essence, does not contain stimulation chemical components, and does not stimulate skins. The magnesium sulfate is directly applied to an affected part, and the magnesium sulfate wet application has the advantages of being long in effect time, small in use amount, convenient and fast to use, heat-preserving and moisture-preserving and not affecting other clinical treatment. In addition, price is low, and simultaneously, work load of medical personnel can be reduced.

Owner:朱修桥

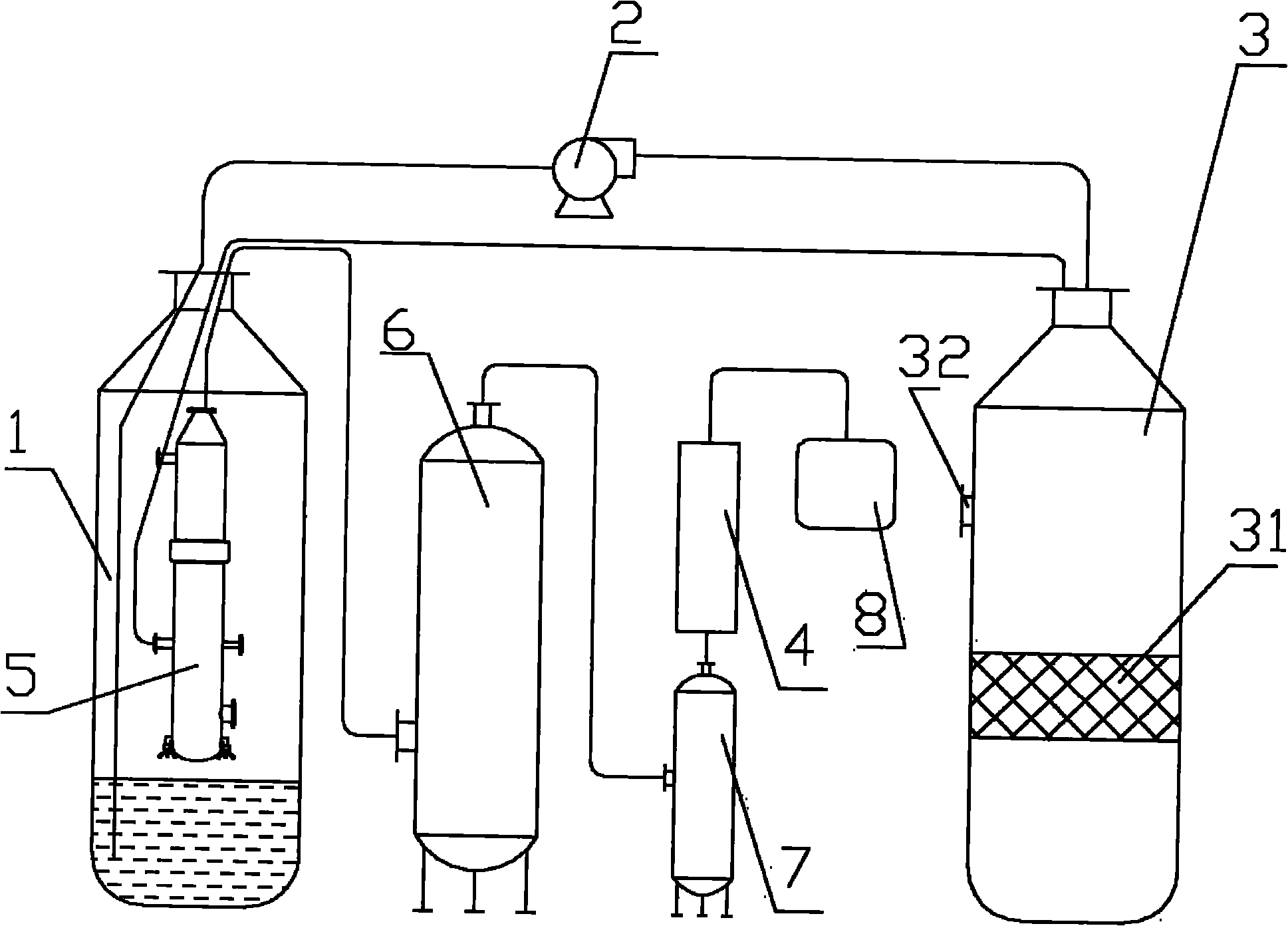

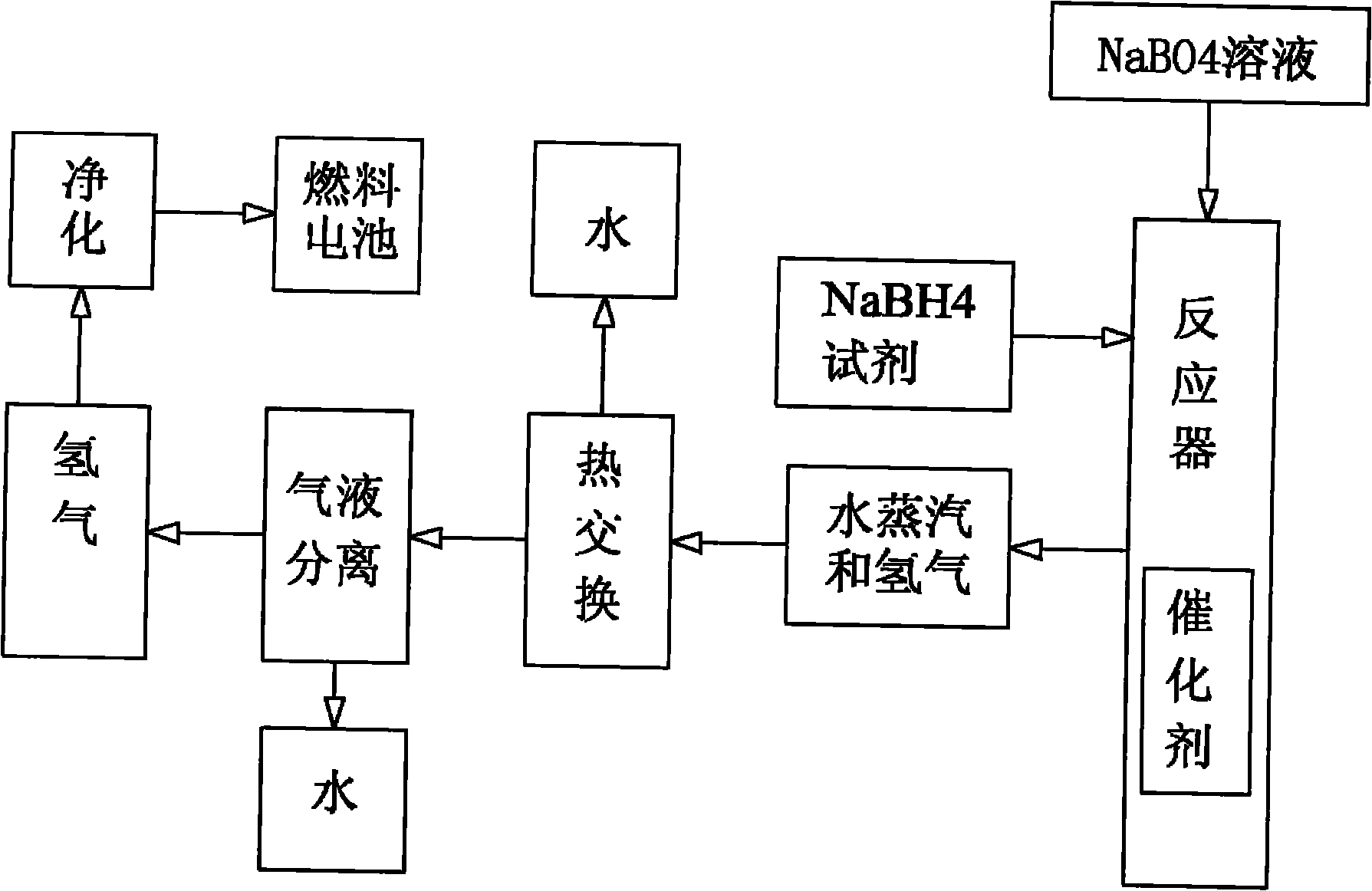

Production process and equipment for preparing hydrogen by hydrolyzing NaBH4 of fuel cell

The invention discloses a production process for preparing hydrogen by hydrolyzing NaBH4 of a fuel cell. The production process comprises the following steps of: a, adding a catalyst; b, adding a reaction solvent; c, performing gas-liquid separation; and d, purification, namely further purifying the hydrogen obtained after gas-liquid separation to remove impurities, metals, nonmetallic ions and salts, wherein after the purified hydrogen reaches 99.99 percent which meets the standard of industrial pure hydrogen, the hydrogen is supplied to the fuel cell. Production equipment for preparing the hydrogen by hydrolyzing the NaBH4 of the fuel cell comprises a liquid storage tank, a liquid conveying pump, a catalyst frame and a purifier, wherein 15 to 30 percent NaBO4 solution is stored in the liquid storage tank; a cooled heat exchanger is fixed in the liquid storage tank; the liquid conveying pump pumps the NaBO4 solution into a reaction tank; a water-cooled tube of the cooled heat exchanger is extended into the reaction tank; the catalyst is placed on the catalyst frame; the reaction tank is communicated with a steam pipeline of the cooled heat exchanger; the air outlet pipeline of the cooled heat exchanger is connected to the purifier; and the purifier supplies the hydrogen to the fuel cell. By the method and the equipment, the purity of the produced hydrogen is high, the specific energy of a system is high and the catalyst can be repeatedly used; and the equipment has high safety performance and long service life.

Owner:浙江永洋复合材料科技有限公司

Catalyst for reducing dioxin emission in waste incineration

InactiveCN101693198AActiveNot poisonedDispersed particle separationCatalyst activation/preparationBiological activationPalladium oxide

The invention discloses a catalyst for reducing dioxin emission in waste incineration, consisting of the following components by weight percent: 1 to 6 percent of cerium oxide, 1 to 10 percent of palladium oxide, 0.5 to 3 percent of yttria and the balance of titanium dioxide. On the condition without high temperature, the catalyst has activation and can lead the waste to be fully oxidized and incinerated, thereby reducing the generation amount of the dioxin. The catalyst does not use precious metals, and generated HCl does not lead the catalyst to be poisoned, thus prolonging the service life and also lowering the cost.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

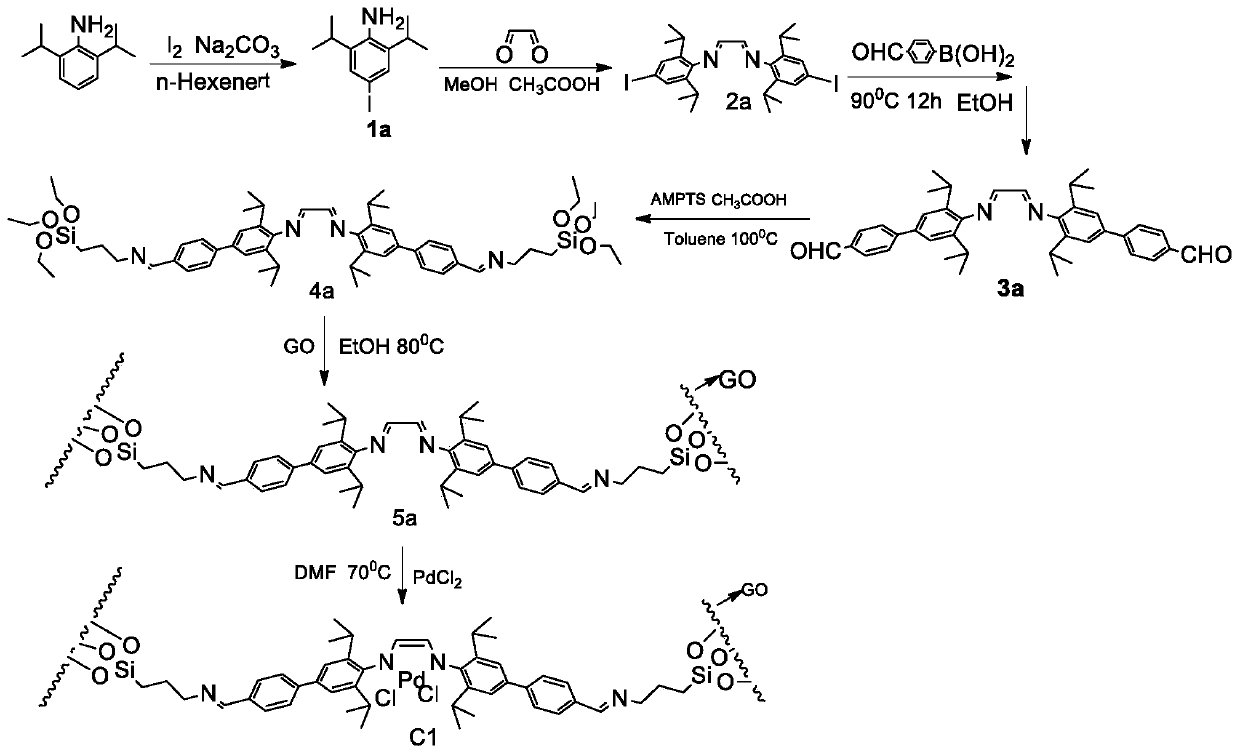

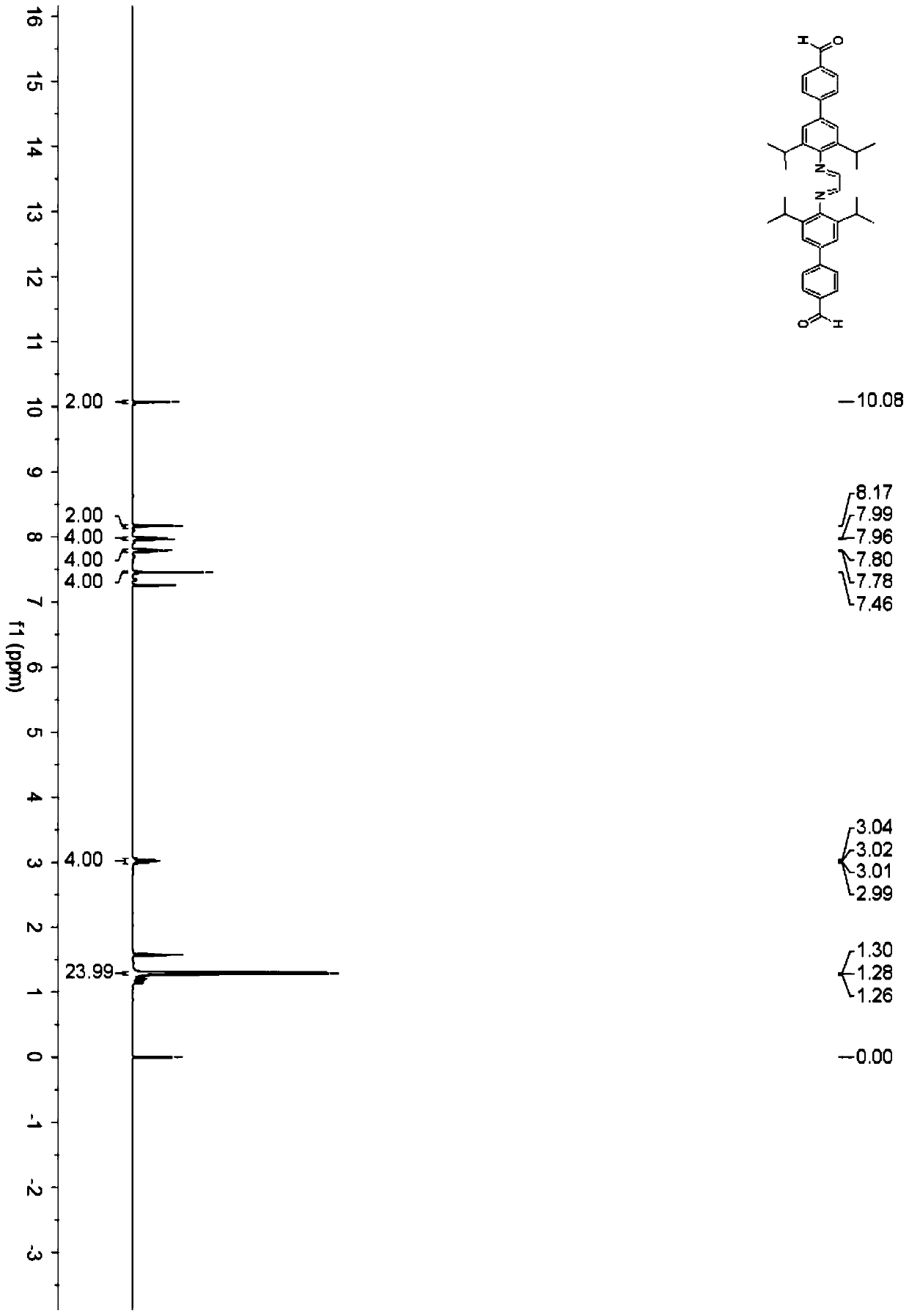

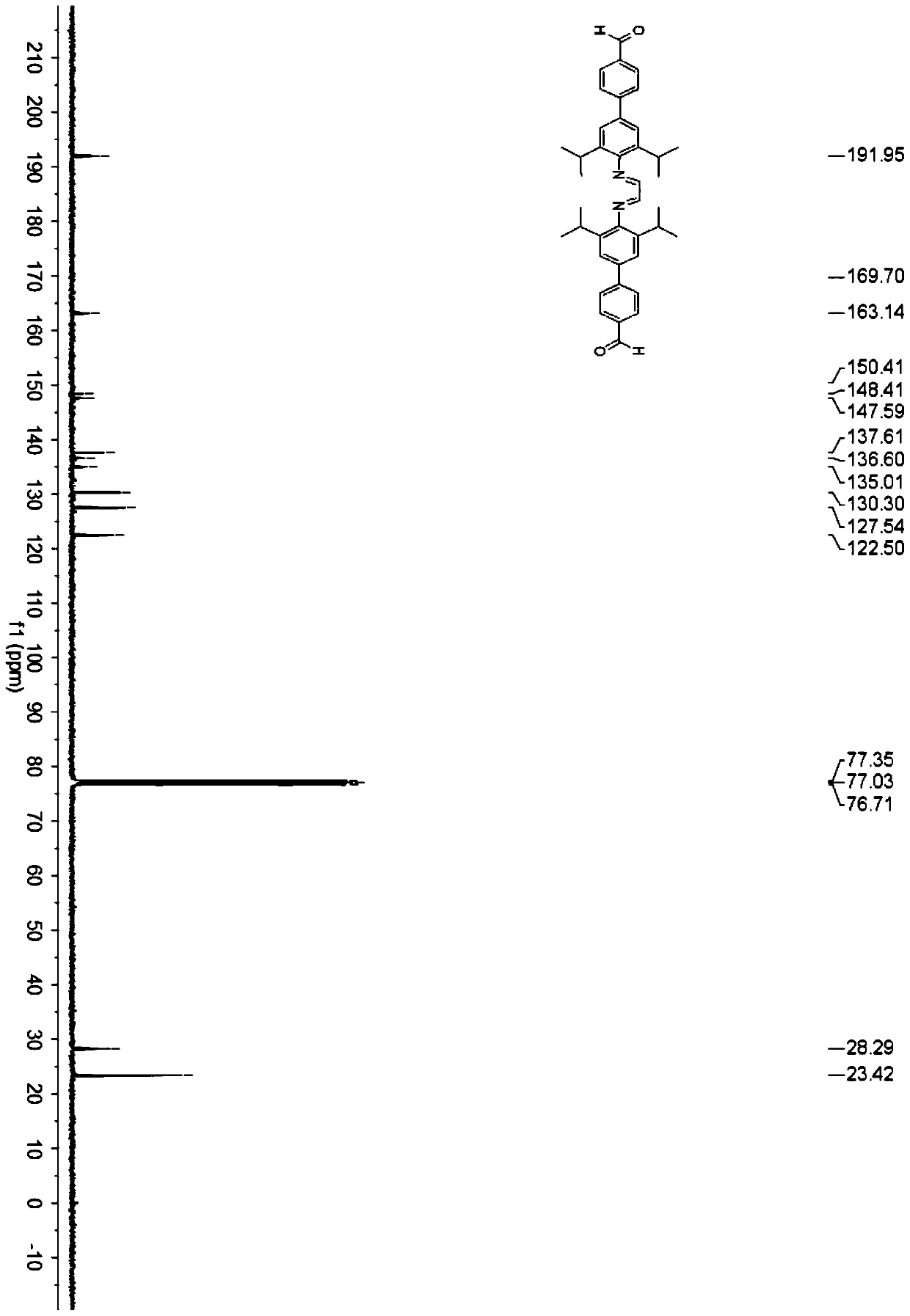

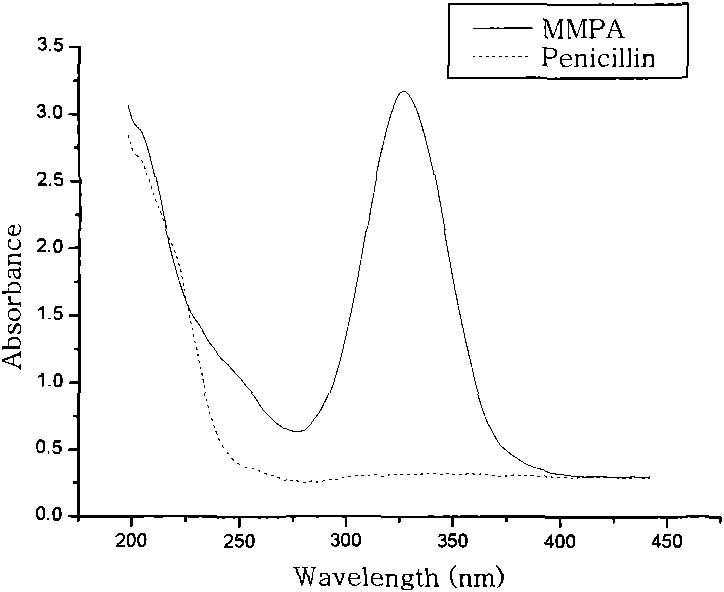

Preparation method and application of graphene-oxide-loaded diimine-coordinated palladium

ActiveCN110302836ASmall hindranceGuaranteed reuseGroup 4/14 element organic compoundsCarboxylic acid nitrile preparationSilane couplingOrganic synthesis

The invention discloses a preparation method of graphene-oxide-loaded diimine-coordinated palladium, and application of the graphene-oxide-loaded diimine-coordinated palladium serving as a catalyst inorganic synthesis reactions. The preparation method of the graphene-oxide-loaded diimine-coordinated palladium includes the following steps: 1) reacting aldehyde-containing diimine with a silane coupling agent to obtain a silane coupling agent modified diimine ligand, 2) reacting the silane coupling agent modified diimine ligand with graphene oxide to obtain a graphene-oxide-loaded diimine ligand; 3) reacting the graphene-oxide-loaded diimine ligand with a palladium salt. The obtained catalyst can efficiently catalyze Suzuki coupling reactions and direct C-H arylation reactions at a very lowdosage; the ligands are firmly loaded on graphene by Schiff base bonding, and accordingly, the catalyst can be recycled for many times and has good application and promotion prospects.

Owner:GUANGDONG PHARMA UNIV

Penicillenic acid mercaptan mercuric salt and preparing method thereof

InactiveCN101654460AStable in natureNot poisonedMercury organic compoundsChemical industryMercuric ion

The invention discloses a penicillenic acid mercaptan mercuric salt and a preparing method thereof, belonging to the technical field of chemical industry. The method comprises the following steps to prepare penicillenic acid mercaptan mercuric salt: 1. under the existence of iminazole, causing penicillin G sodium salt or penicillin G potassium salt to react with mercuric chloride; 2. purifying thereaction product to prepare the penicillenic acid mercaptan mercuric salt. The preparing method of the invention has simple reaction system and simple preparing process; the prepared penicillenic acid mercaptan mercuric salt has stable quality and can serve as the hapten of mercuric ions.

Owner:SHANGHAI JIAO TONG UNIV

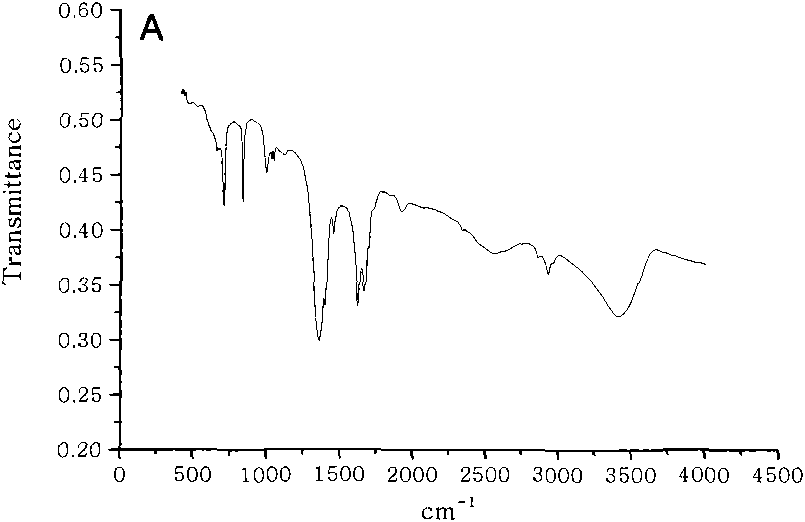

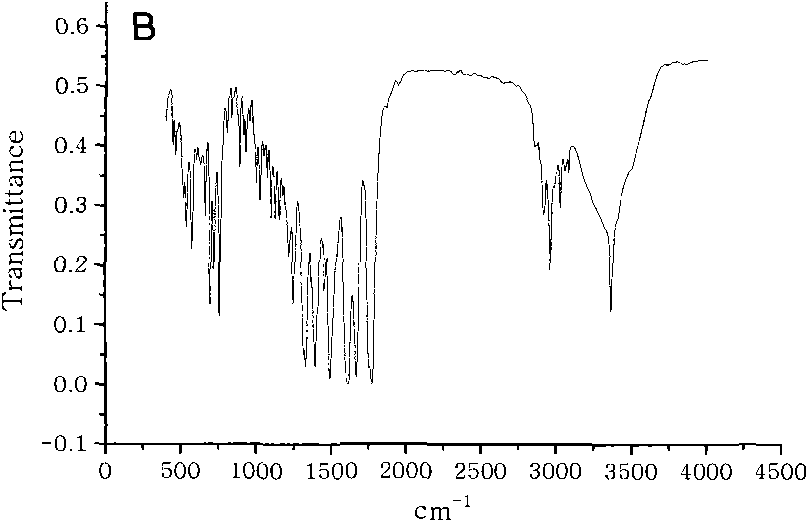

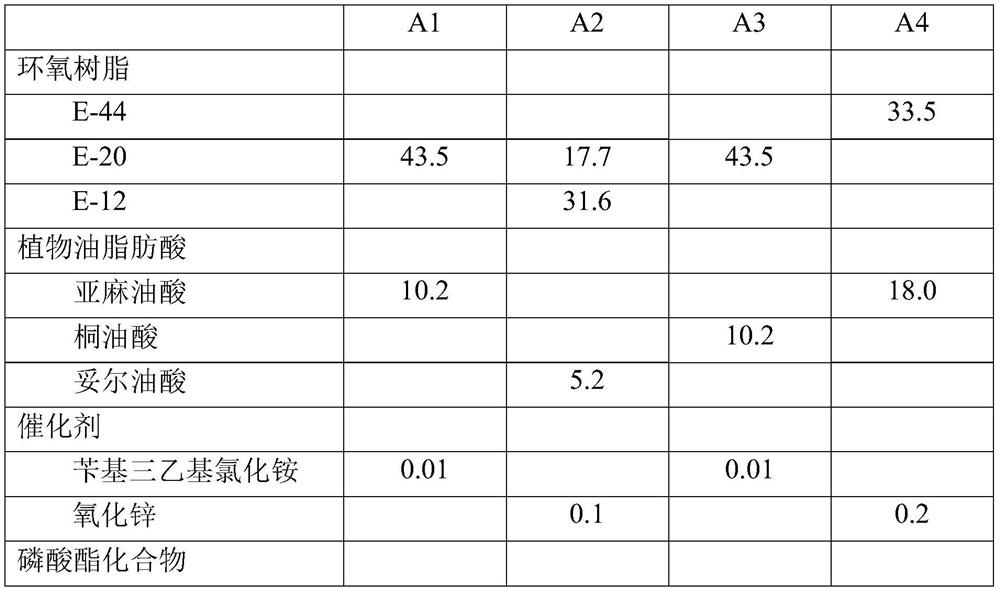

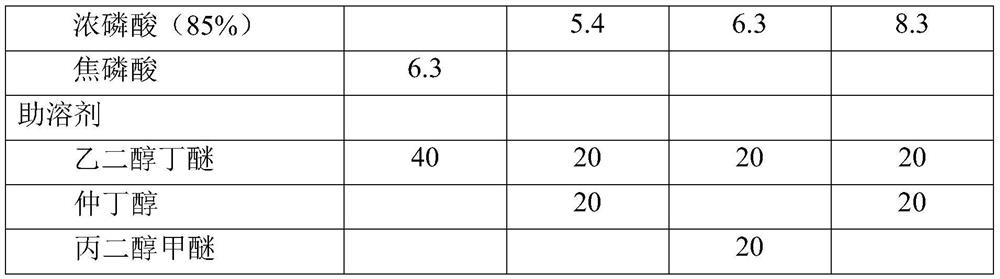

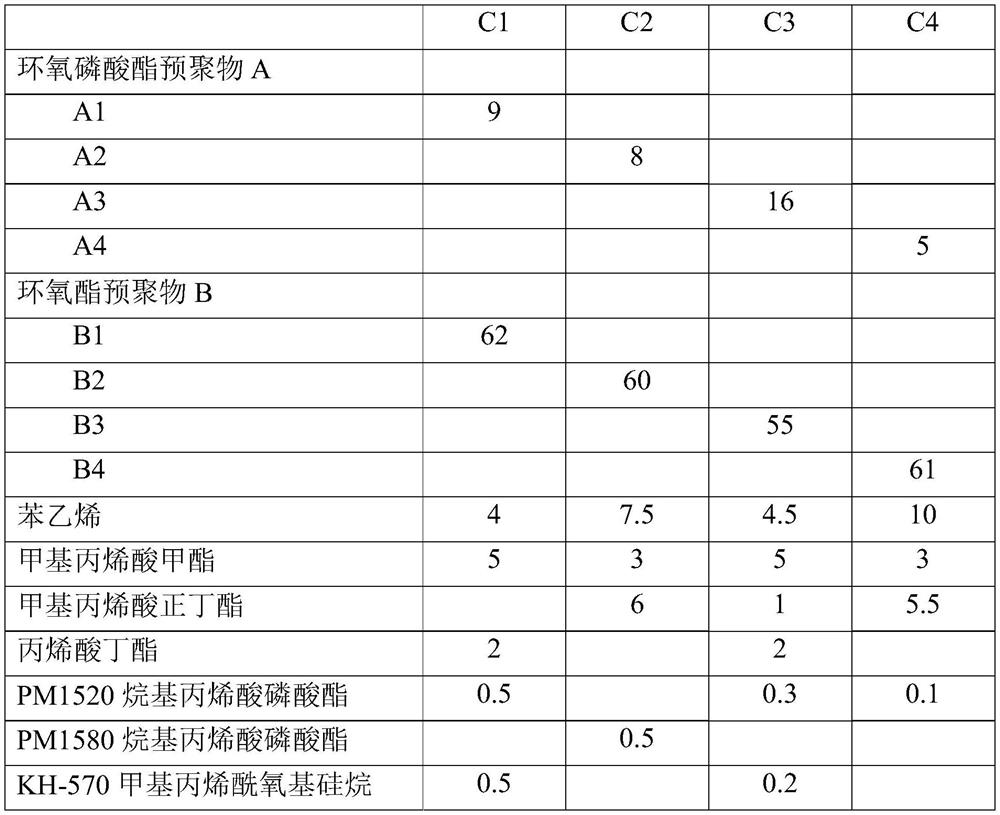

Phosphate-modified waterborne epoxy ester resin and anti-corrosive primer thereof, and preparation methods of phosphate-modified waterborne epoxy ester resin and anti-corrosive primer

PendingCN114044881AFast dryingHigh glass transition temperatureAnti-corrosive paintsEpoxyPhosphoric Acid Esters

The invention relates to phosphate-modified waterborne epoxy ester resin and an anti-corrosive primer thereof, and preparation methods of the phosphate-modified waterborne epoxy ester resin and the anti-corrosive primer. A scheme provided by the invention comprises the phosphate-modified waterborne epoxy ester resin and the preparation method thereof. The waterborne epoxy ester anti-rust primer with excellent anti-rust performance is prepared by taking the phosphate-modified waterborne epoxy ester resin as a base material and cooperatively using a non-toxic and efficient anti-rust pigment. Compared with the prior art, epoxy resin and phosphoric acid are esterified to synthesize epoxy phosphate, then the epoxy phosphate and acrylate monomers are subjected to graft copolymerization, so the phosphate modified waterborne epoxy ester resin with excellent performance is prepared, and the salt spray resistance of the anti-rust primer is further improved.

Owner:上海华谊涂料有限公司

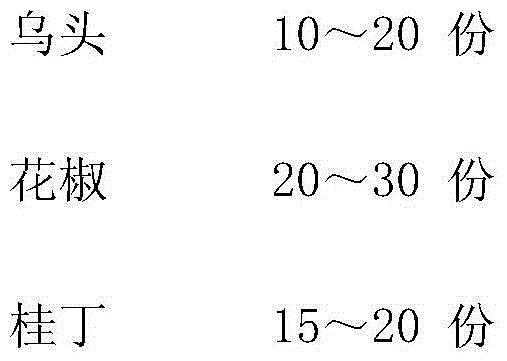

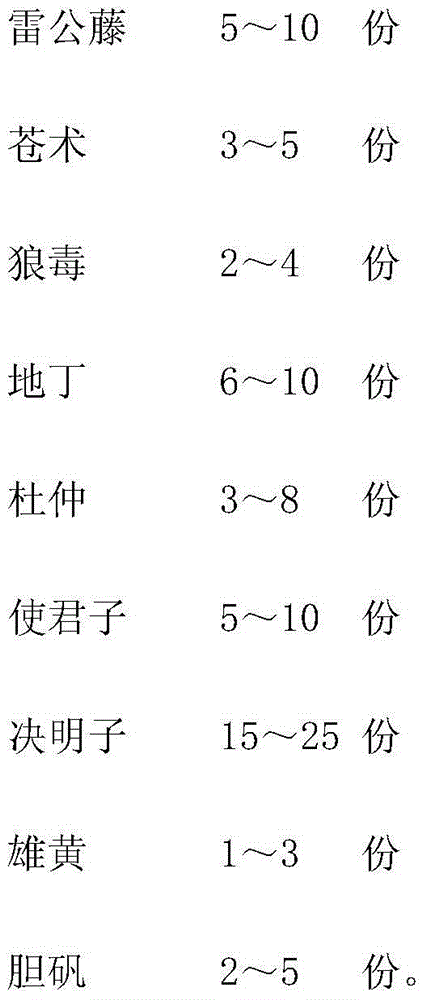

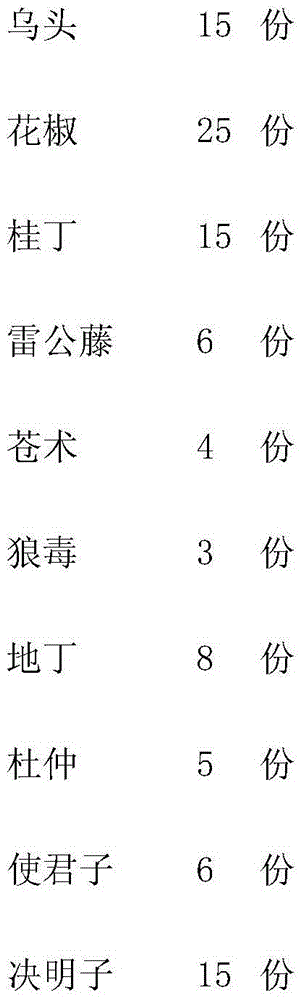

Fungicide for controlling willow pests and preparation method of fungicide

The invention relates to a fungicide for controlling willow pests. The fungicide comprises aconite, Chinese prickly ash, fructus cinnamomi, tripterygium wilfordii, atractylodes, radix euphorbiae lantu, viola, eucommia ulmoides, quispualis indica and semen cassia. The method comprises the following steps: weighing various components according to the amount; respectively adding water and decocting, extracting effective components, cooling, and then merging an extract liquid; adding realgar and chalcanthite under a micro-heating condition; and stirring evenly to prepare a finished product. The effective components of the traditional Chinese medicines in the fungicide are matched with one another, so that willow pests such as long-horned beetle, clania variegata snellen and cleoporus varriabilis can be effectively prevented and treated; the death knockdown rate within 3 days after the fungicide is sprayed is over 93%; the willow surrounding environment is free of an obvious peculiar smell; birds are not poisoned; the environment is not polluted; and the physical health of people is not harmed.

Owner:天津市利源祥苗木种植专业合作社

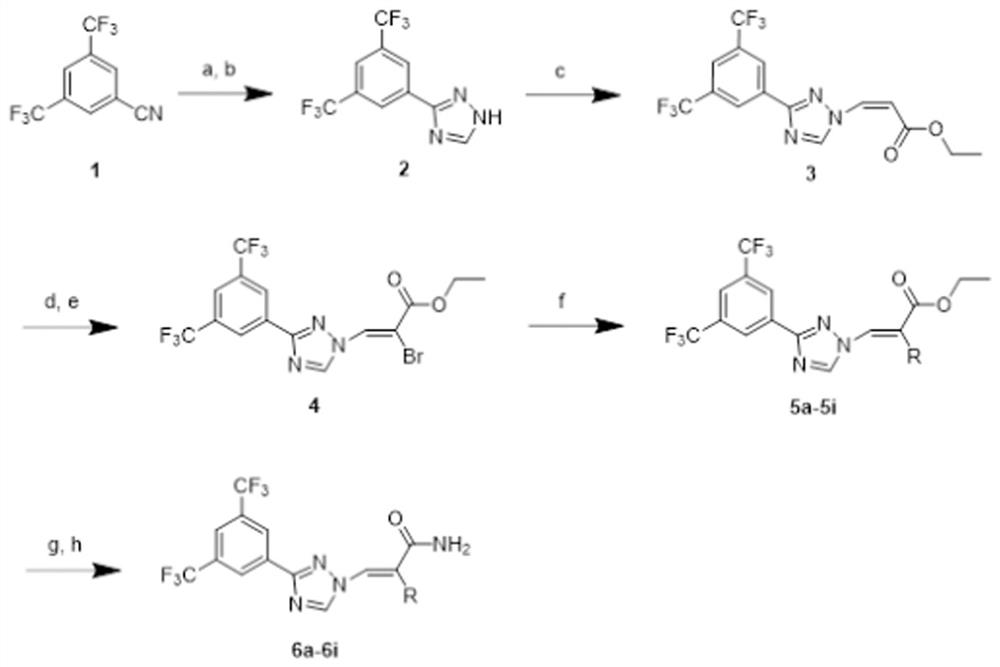

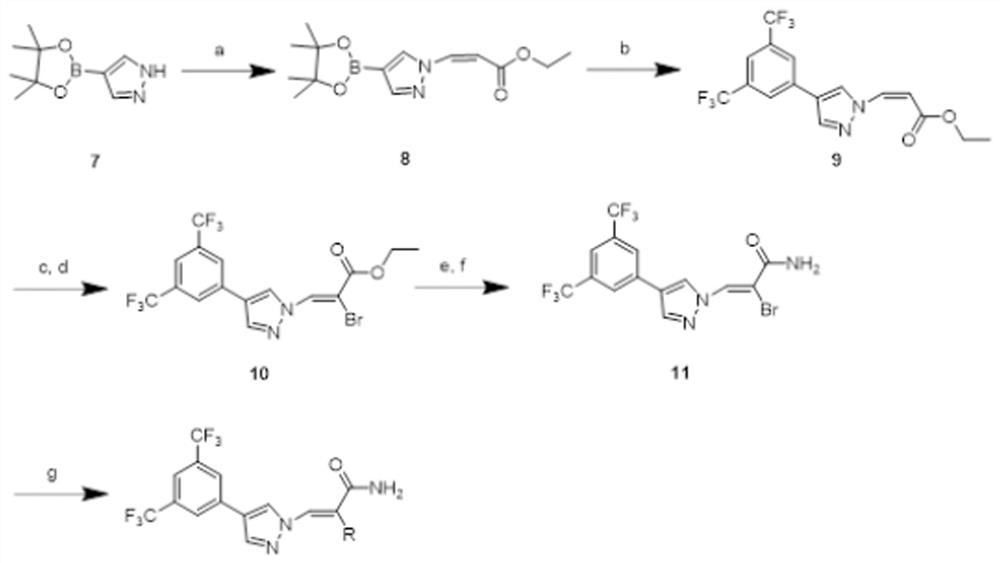

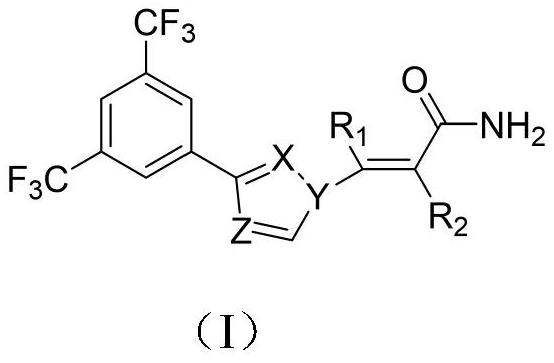

Azole derivative or pharmaceutically acceptable salt thereof as well as preparation method and application of azole derivative or pharmaceutically acceptable salt thereof

PendingCN112538069ANovel structureBlock proliferationOrganic active ingredientsOrganic chemistryDiseaseBiochemistry

The invention discloses an azole derivative or a pharmaceutically acceptable salt thereof and a preparation method of the azole derivative or pharmaceutically acceptable salt thereof. The structure ofthe azole derivative is as shown in the specification, and compared with the prior art, the invention provides an azole compound with a novel structure and a CRM1 protein inhibition function, and theazole compound is used as a CRM1 protein inhibitor and can block tumor cell proliferation and inhibit tumor cell apoptosis, and induce tumor cell apoptosis, and therefore, the compound can be used for treating and preventing various diseases of human and animals, such as malignant tumors, and the effect is remarkable and better.

Owner:SUZHOU AIHE PHARM TECH CO LTD

Rape seed cake-containing chicken feed

InactiveCN102987072AReduce manufacturing costNot poisonedAnimal feeding stuffPotassium permanganateAnimal science

The invention discloses a rape seed cake-containing chicken feed. The chicken feed comprises the following ingredients in percentage by weight: 55-60 percent of corn, 12-15 percent of bran, 12-15 percent of chaff, 5-7 percent of bean pulp, 2-3 percent of bone meal, 2-3 percent of dried earthworm body, 5-8 percent of rape seed cake, and 0.1-0.3 percent of salt. The bone meal is prepared by soaking river clamshell with 0.1% potassium permanganate water solution for 10 minutes, then washing, drying and grinding; the dried earthworm body is prepared by drying and grinding eisenia foelida; and the rape seed cake is prepared by grinding, soaking with warm water for 8-12 hours, pouring water, adding clear water, boiling for 1hour, agitating constantly and drying, and then evenly blending into chicken feed. The method is simple and reliable, the production cost of the chicken feed is lowered, and the nutrient ingredients can be increased.

Owner:镇江市丹徒区瑞通畜禽养殖专业合作社

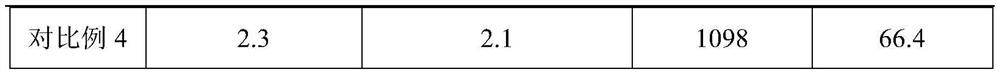

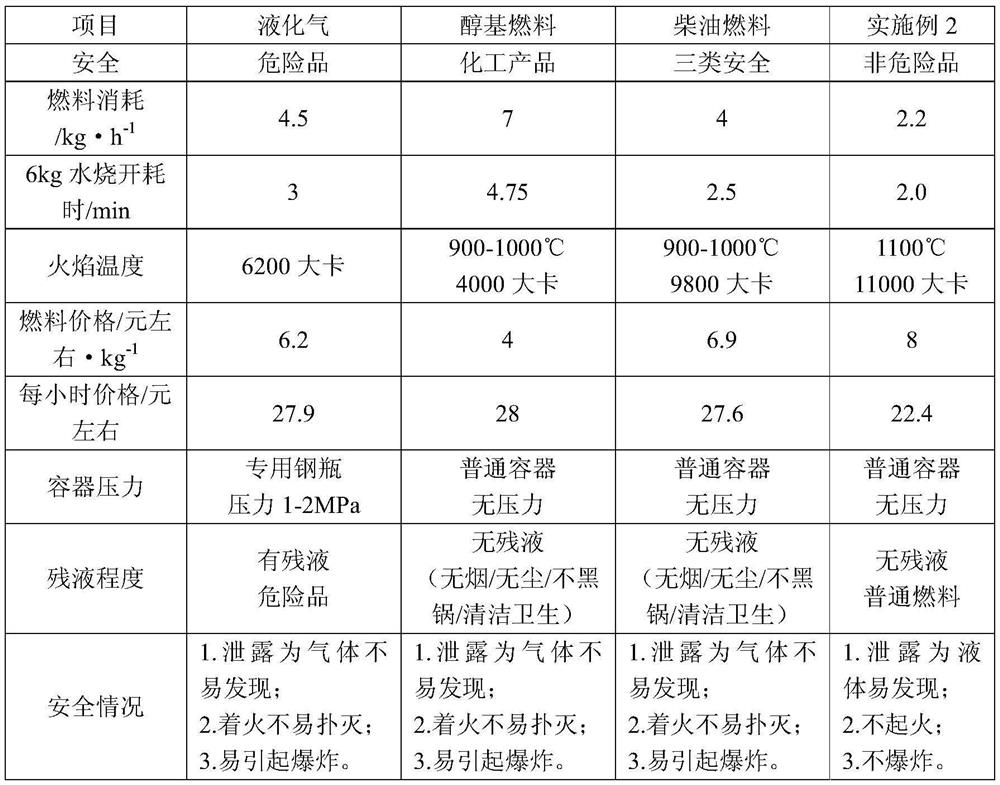

Alcohol-powered novel environment-friendly fuel and manufacturing method thereof

InactiveCN102827648AHigh calorific valueImprove performanceLiquid carbonaceous fuelsAlcoholNew energy

The invention discloses an alcohol-powered novel environment-friendly fuel and a manufacturing method of the fuel. The fuel is a liquid fuel produced by ester exchange reaction with methanol or ethanol as a raw material under the catalysis of an additive. The formula of per cent of fuel contains 80-85% of alcohol (methanol or ethanol), 2% of additive and not more than 18% of water, wherein the additive contains 0.5% of solvent oil, 0.1% of isopropanol, 0.1% of ethylamino alcohol, 0.8% of acetone, 0.4% of glycerol and 0.1% of sulfonated oil. The production manner comprises the steps of: preparing the additive by mixing, uniformly stirring the alcohol, the additive and water, and standing for 4h, wherein the fuel can be used after inspection by sampling to be qualified. The fuel is suitable for guesthouses, restaurants, plants schools and households to be used as a clean environment-friendly fuel serving a new energy.

Owner:ZHEJIANG HECHENG ENERGY

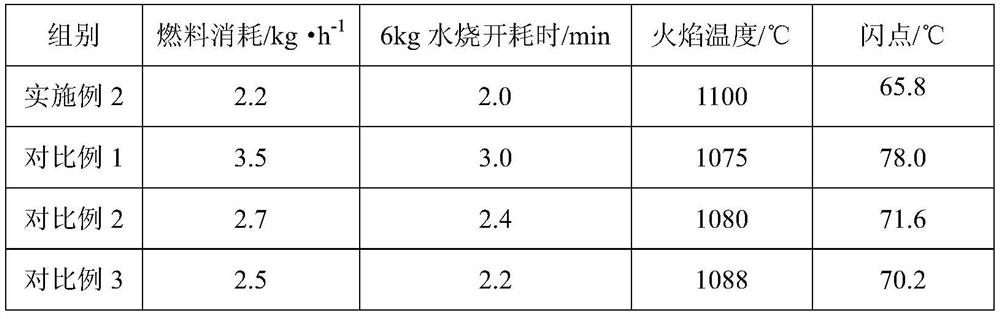

Energy-saving environment-friendly alcohol-free vegetable oil fuel and preparation method thereof

InactiveCN112940807AHigh calorific valueImprove stabilityLiquid carbonaceous fuelsFuel additivesVegetable oilTert butyl

The invention discloses an energy-saving and environment-friendly alcohol-free vegetable oil fuel which comprises the following raw materials: vegetable oil, a POSS-phosphorylated vegetable oil polymer, methyl tertiary butyl ether, isopropanol, ethylene glycol, glycerol, absolute ethyl alcohol, magnesium powder, ferrocene and water. The invention also discloses a preparation method of the energy-saving and environment-friendly alcohol-free vegetable oil fuel, which comprises the following steps: S1, preparing methyl tert-butyl ether, isopropanol, ethylene glycol, glycerol and absolute ethyl alcohol into a mixing agent, and adding the mixing agent and the POSS-phosphorylated vegetable oil polymer into the vegetable oil to prepare a mixed solution; s2, adding water into the mixed solution, carrying out ultrasonic dispersion, and uniformly stirring to obtain a water-in-oil mixed solution; and S3, adding the magnesium powder and the ferrocene into the water-in-oil mixed solution, and uniformly stirring to obtain the magnesium-in-oil composite material. The vegetable oil fuel prepared by the invention is low in flash point, has better properties than liquefied gas, alcohol-based fuel and diesel fuel, and has the advantages of energy conservation, environmental protection, safety, cleanness, high efficiency and good economic benefit.

Owner:NANJING XINGJING CHEM

A kind of two-component silicone potting glue and preparation method thereof

ActiveCN106947428BAdd lessDoes not affect liquidityNon-macromolecular adhesive additivesPtru catalystEngineering

The invention provides a two-component organosilicon pouring sealant. The two-component organosilicon pouring sealant comprises a component A and a component B with equal mass, wherein the component A comprises 100 parts of a base material, a platinum catalyst with the mass of platinum accounting for 1 to 500 ppm of the mass of the component A, and 1 to 5 parts of an adhesion promoter; the component B comprises 100 parts of a base material, 0.2 to 20 parts of a crosslinking agent and 0.002 to 0.5 part of an inhibitor; and the adhesion promoter is nitrogen heterocycle containing polycyclic siloxane. The invention belongs to the technical field of pouring sealants. The two-component organosilicon pouring sealant provided by the invention has the advantages of good flame-retardant performance, adhesion properties with a substrate, excellent fluidity, no poisoning caused by a platinum catalyst, environmental protection, safety, and easy operation.

Owner:广东皓明有机硅材料有限公司

Fly killing bait and its preparing method

InactiveCN1615697AImprove insecticidal effectExtension of timeBiocideAnimal repellantsEmulsionSucrose

The present invention discloses a fly killing bait and its preparation process. The fly killing bait contains natural pyrethrins as effective component in 0.1-3 wt%, and synergist in the amount of 1-10 times that of pyrethrins. Specially, 5-15 wt% concentration water emulsion of pyrethrins in 5-20 portions, cane sugar in 75-85 portions, starch in 15-20 portions are mixed while adding synergist and small amount of water to prepare the bait. Natural pyrethrins with few toxicity in optimal amount is used, and it is easily decomposed. The present invention has no residue, no environmental pollution, no harm to people and animal and high fly attracting and killing effect.

Owner:红河森菊生物有限责任公司

Green nuisance-free pig feed and preparation method thereof

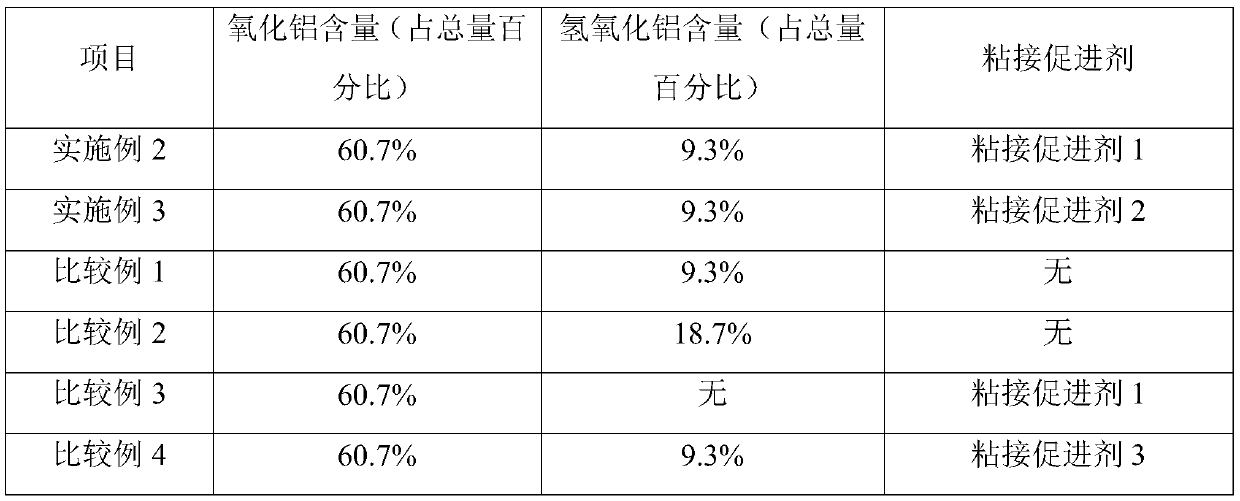

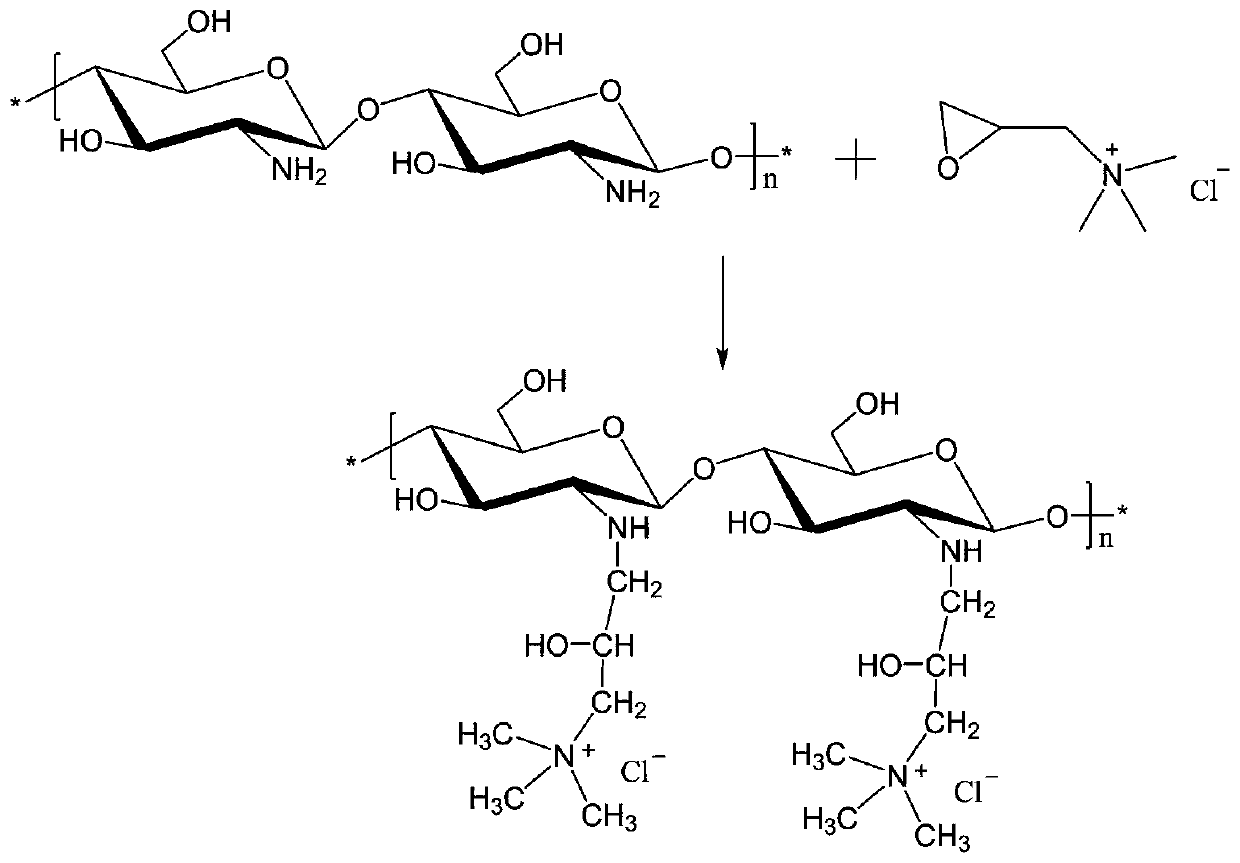

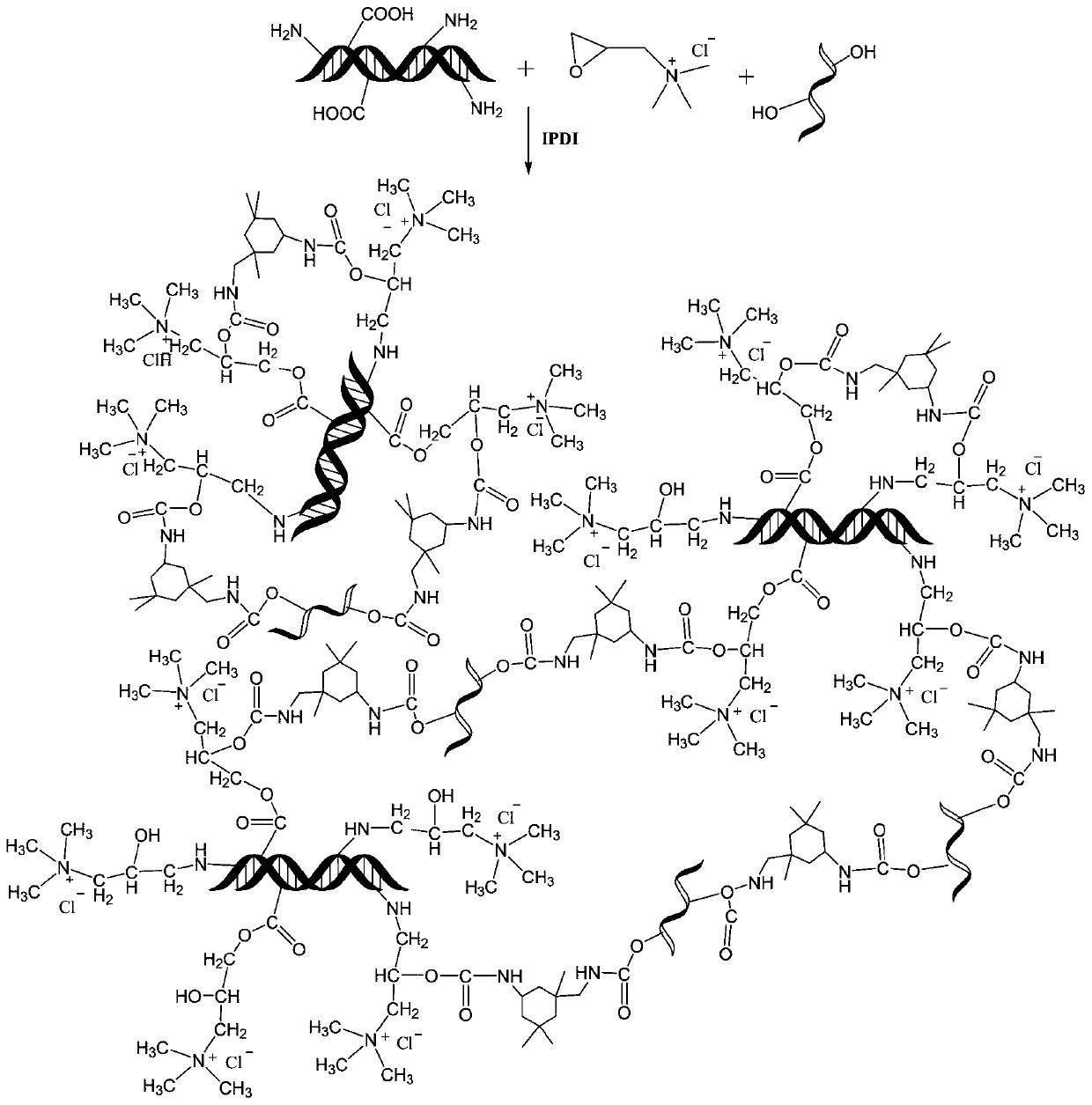

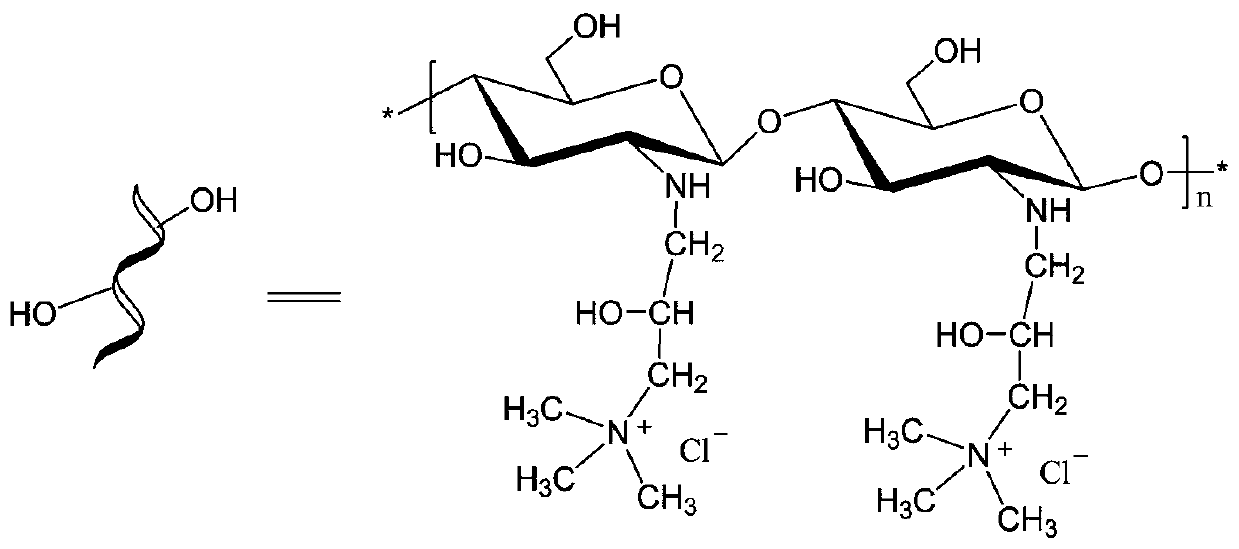

PendingCN109699844AHigh nutritional valueImprove antibacterial abilityFood processingAnimal feeding stuffIsophoroneNutrient

The invention discloses a green nuisance-free pig feed. The green nuisance-free pig feed comprises the following raw materials in parts by weight of 59-63 parts of bagasse, 34-38 parts of corn flour,27-29 parts of distillers' grains, 37-41 parts of soybean meal, 45-51 parts of wheat bran, 38-42 parts of alfalfa, 2.3-2.8 parts of cellulase, 1.2-1.4 parts of xylanase, 4.2-4.5 parts of alkali protease, 18-21 parts of quaternisation crab shells, 0.6-0.8 part of trace elements, 21-22 parts of isophorone, 17-18 parts of glycidyl trimethyl ammonium chloride, 5-7 parts of table salt, 1.3-1.5 parts ofcomplex vitamins and an appropriate amount of water. The used raw materials comprise massive waste crude fibers and macromolecule protein, in the process of preparation of a pig feed, the crude fibers and the macromolecule protein are directly decomposed through a compound enzyme preparation, and the reaction condition can be reasonably controlled, so that the enzymolysis is thorough; an appropriate amount of the isophorone is added, so that micromolecule sugar and amino acid peptide after decomposition, are subjected to alkaline cross-linking fixation, and nutrient substances after enzymolysis cannot run off.

Owner:新昌县大船畈生物科技有限公司

High-energy environmentally-friendly fuel as well as preparation method and application thereof

InactiveCN110229703ALow oxygenIncrease oxygen contentLiquid carbonaceous fuelsFuel additivesVegetable oilHigh energy

The invention discloses a high-energy environmentally-friendly fuel, and in particular relates to the safe and clean fuel which does not contain methanol, does not belong to dangerous chemicals, cannot be directly ignited by open fire, is not easy to burn or explode, and has no toxicity or harm. The fuel has no danger of poisoning and fire due to leakage and overcomes the problem that a current fuel has danger during use. The fuel provided by the invention comprises the following raw materials: 850-1200 parts of industrial vegetable oil, 1.4-2.6 parts of an emulsifying agent, and 0.13-0.28 part of ferrocene. The invention also discloses a preparation method of the high-energy environmentally-friendly fuel. The method comprises the following steps: step 1, preparing materials: weighing theindustrial vegetable oil, the emulsifying agent and the ferrocene according to the above parts; step 2, performing mixing: pouring the industrial vegetable oil into a mixing barrel, after the industrial vegetable oil is completely poured, adding the emulsifying agent into the barrel, and performing mixing under continuous stirring; and step 3, performing secondary mixing, adding the ferrocene into the mixed solution obtained in the step 2, and performing continuous full stirring.

Owner:成都蓝海科创新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com