Green nuisance-free pig feed and preparation method thereof

A pig feed, green technology, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of small enzyme preparation, lower pig feed nutrition, high price, etc., and achieve high antibacterial ability and high nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

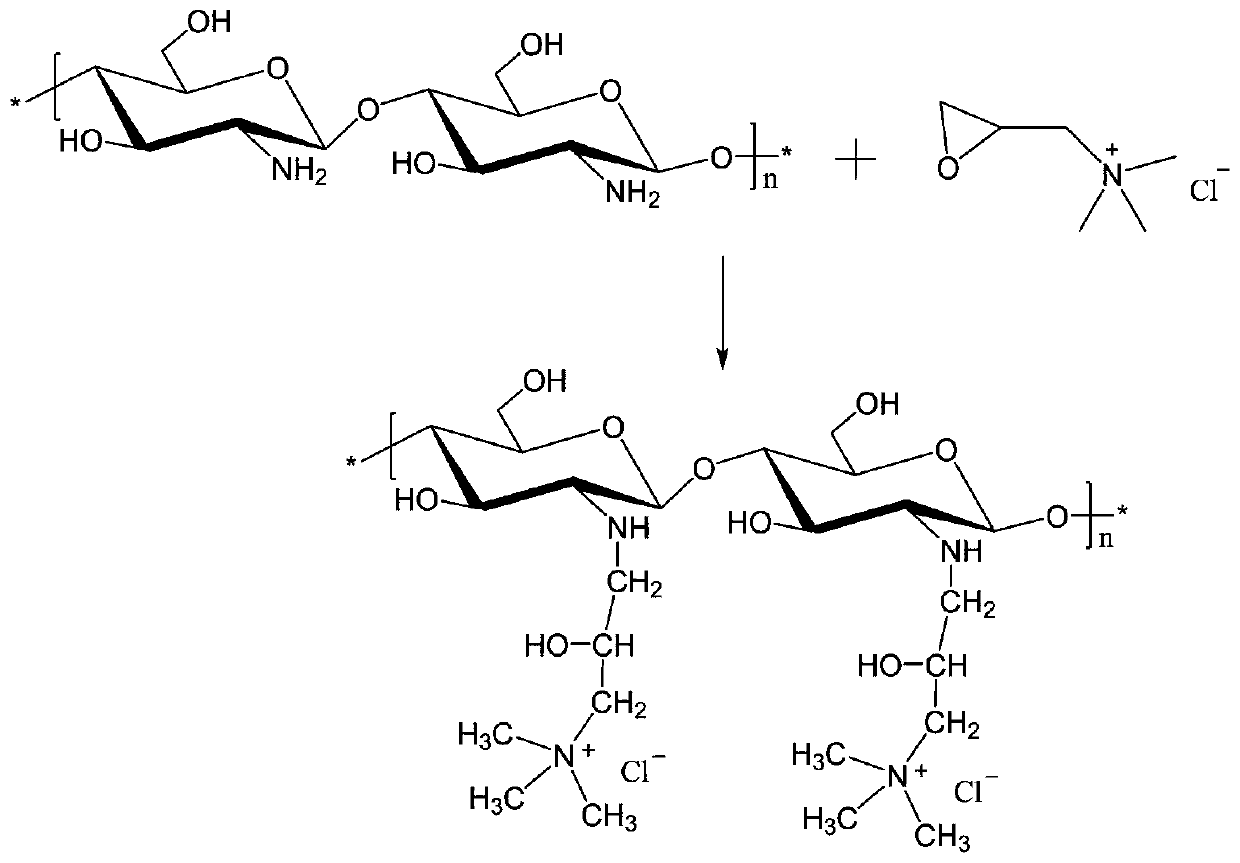

[0031] The specific preparation process of the quaternized ammonium salted crab shell is as follows:

[0032] Step 1: Take 10kg of crab shells, wash them, dry them and grind them, add the ground crab shells to 100L of hydrochloric acid solution with a concentration of 5mol / L and soak for 12 hours, and stir continuously during the soaking process to make the calcium in the crab shells Dissolving, then filtering, washing and drying to obtain pretreated crab shells;

[0033] Step 2: Add the pretreated crab shells obtained in step 1 into a 40% sodium hydroxide solution, heat up to 50° C. for deacetylation reaction for 6 hours, then filter, wash and dry to obtain chitosan;

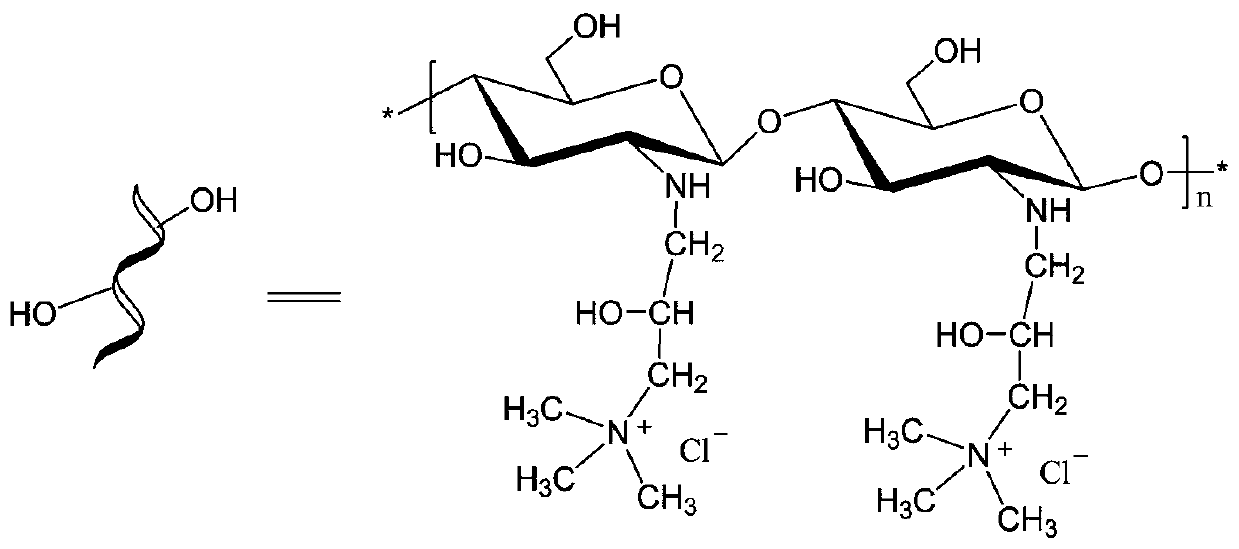

[0034] Step 3: Add the chitosan prepared in step 2 to a 5% acetic acid solution to form a chitosan solution with a concentration of 0.05g / mL, and then add 2,3-cyclone to the 100L chitosan solution Oxypropyltrimethylammonium chloride, stirred and reacted at 50°C for 7h, filtered, washed and dried to obtain quat...

Embodiment 2

[0036] A preparation method of green pollution-free pig feed, the specific preparation process is as follows:

[0037] In the first step, 59kg of bagasse, 37kg of soybean meal, 45kg of wheat bran, 38kg of alfalfa grass and 27kg of distiller's grains were dried and crushed to a particle size of less than 1cm;

[0038] In the second step, edible vinegar is added into water and configured into a solution of pH=5.8-6, then 2.3kg of cellulase and 1.2kg of xylanase are added thereto, and bagasse, wheat bran, Add alfalfa grass and distiller's grains into the solution, raise the temperature to 55°C and stir at a low speed for 72 hours, then filter, dry the filter residue for later use, and keep the filtrate for later use;

[0039] In the third step, add 34kg of cornmeal and the residue filtered in the first step into water, adjust the pH=8.2-8.5, add 4.2kg of alkaline protease to it at the same time, raise the temperature to 50°C and stir at low temperature for 3 days, and filter the ...

Embodiment 3

[0043] A preparation method of green pollution-free pig feed, the specific preparation process is as follows:

[0044] In the first step, 63kg of bagasse, 41kg of soybean meal, 51kg of wheat bran, 42kg of alfalfa grass and 29kg of distiller's grains were dried and crushed to a particle size of less than 1cm;

[0045] In the second step, edible vinegar is added into water to be configured into a solution of pH=5.8-6, then 2.8kg of cellulase and 1.4kg of xylanase are added thereto, and bagasse, wheat bran, Add alfalfa grass and distiller's grains into the solution, raise the temperature to 55°C and stir at a low speed for 72 hours, then filter, dry the filter residue for later use, and keep the filtrate for later use;

[0046] In the third step, add 38kg of cornmeal and the residue filtered in the first step into water, adjust the pH=8.2-8.5, add 4.5kg of alkaline protease to it at the same time, raise the temperature to 50°C and stir for 3 days at low temperature, and filter th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com