Preparation method for UV-induced photografted charged nanofiltration membrane and product thereof, and application of product

A nanofiltration membrane and external connection technology, applied in the field of nanofiltration membranes, can solve the problems of small flux, achieve high desalination rate, controllable membrane filtration performance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

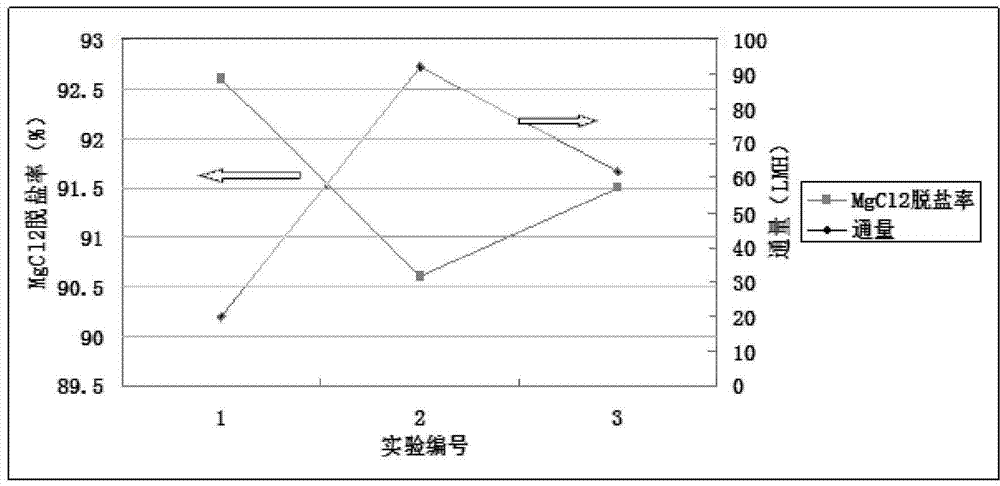

Embodiment 1

[0038] Example 1 (control group)

[0039] A methacryloxyethyl trimethylammonium chloride aqueous solution with a concentration of 500g / L is configured, and a polysulfone ultrafiltration membrane with a molecular weight cut-off of 68000 is placed in a grafting tank, which is made of stainless steel with edges Manufactured reaction vessel. Pour the aqueous solution of methacryloyloxyethyltrimethylammonium chloride into the grafting tank, immerse the polysulfone ultrafiltration membrane, and make the thickness of the liquid membrane 3mm, and irradiate the grafting under a 2000w power ultraviolet lamp for 10 minutes ( The effective light intensity on the film surface is measured as 12mW / cm 2 ), take it out and wash it with deionized water.

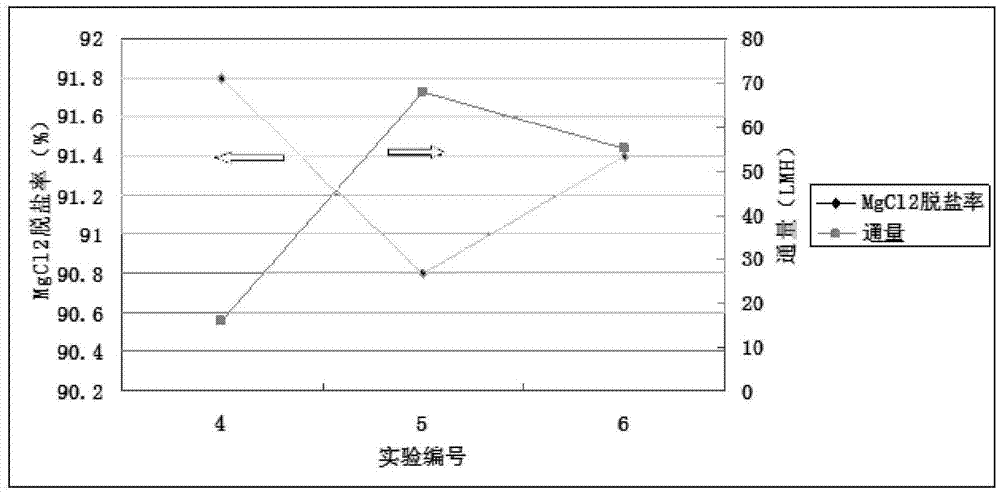

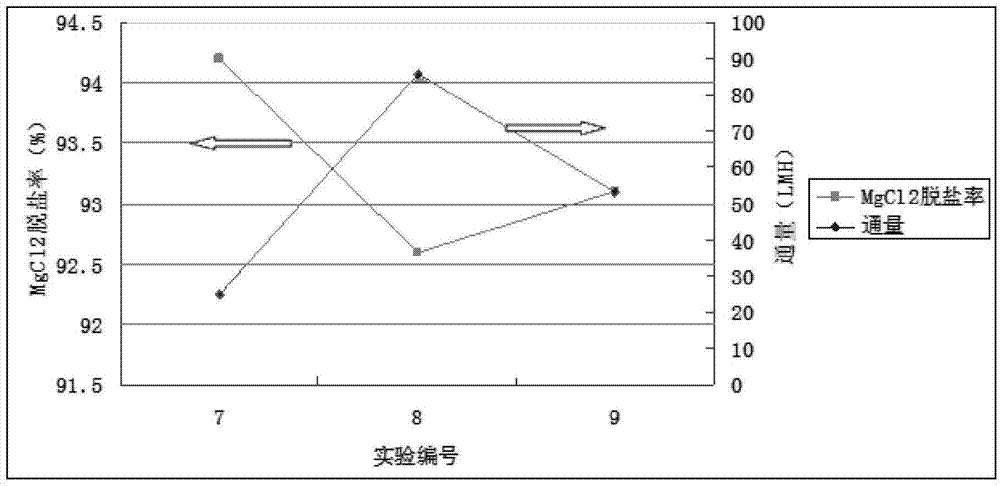

Embodiment 2

[0041] Configure an aqueous solution of methacryloxyethyl trimethylammonium chloride with a concentration of 500g / L, and add p-hydroxyanisole (polymerization inhibitor) with a mass volume concentration of 1g / L aqueous solution to the aqueous solution, and 1% mass Concentration of sodium formate (chain transfer agent), mix well. The polysulfone ultrafiltration membrane with a molecular weight cut-off of 68000 was immersed in it, and the other steps were the same as in Example 1.

Embodiment 3

[0043] Configure a methacryloxyethyl trimethylammonium chloride aqueous solution with a concentration of 500g / L, add p-hydroxyanisole (polymerization inhibitor) with a mass volume concentration of 0.5g / L aqueous solution to the aqueous solution, and 1% Mass concentration of sodium formate (chain transfer agent), mix well. The polysulfone ultrafiltration membrane with a molecular weight cut-off of 68000 was immersed in it, and the other steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com