Low-temperature rapid black nickel water

A black nickel, low temperature technology, applied in the field of low temperature rapid black nickel water, can solve the problems of energy loss, increased processing cost, time loss, etc., and achieves the effects of stable performance, long service life and convenient operation

Inactive Publication Date: 2012-03-28

东莞市宝中实业发展有限公司

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This causes a large amount of energy loss, greatly increa

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

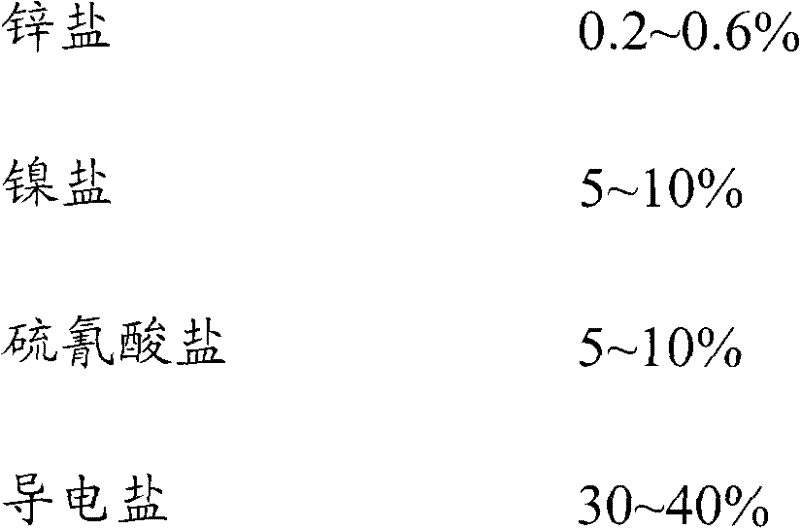

[0036] A kind of fast low-temperature black nickel water comprises the following components by mass fraction:

[0037]

Embodiment 2

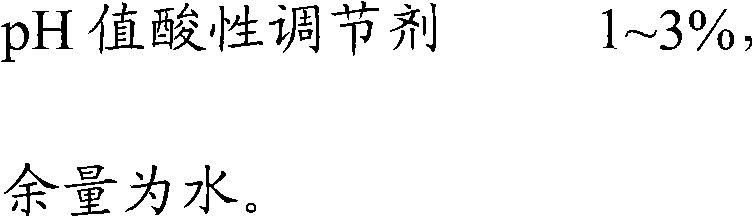

[0039] A kind of fast low-temperature black nickel water comprises the following components by mass fraction:

[0040]

Embodiment 3

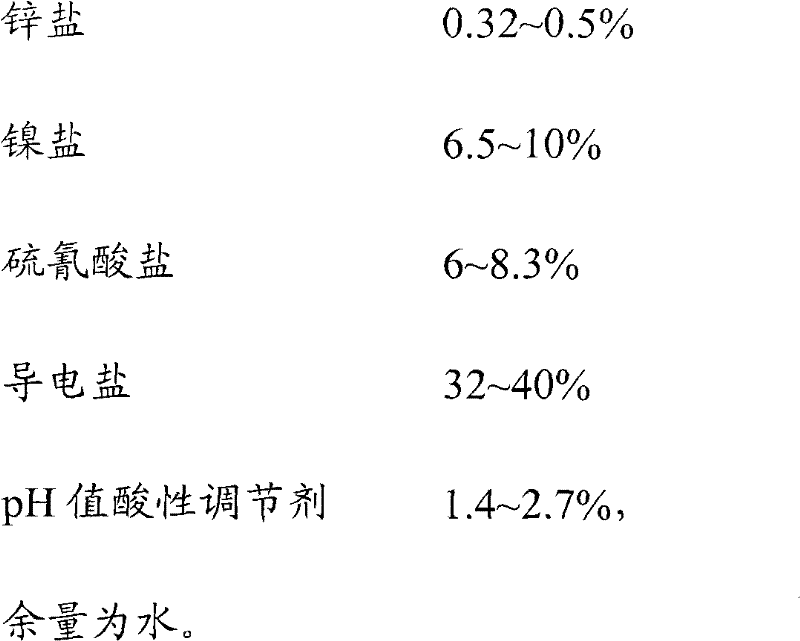

[0042] A kind of fast low-temperature black nickel water comprises the following components by mass fraction:

[0043]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to rapid low-temperature black nickel water for nickel plating and copper plating post-processing. The black nickel water contains components such as zinc salt, nickel salt, thiocyanate, conductive salt, water and the like. The black nickel water is characterized in that the operating temperature is 25-50 DEG C; the operating time is 1-5 min; and pH value is 4.5-5.5. The black nickel water is prepared according to the following steps of: adding 50-70% of water in the raw materials into a stirring device; successively pouring other components; finally adding the rest of the water; and stirring for at least 5 minutes to obtain the finished product. The black nickel water produced in the invention is clear, has stable performance and wide range of temperature and current density, is convenient to operate, and has long service life. As the product can be used at the temperature of 30-40 DEG C, electric energy consumed during heating process is greatly saved; in addition, the heating time is short, thus saving time.

Description

technical field [0001] The invention belongs to the technical field of metal material surface treatment, and in particular relates to a low-temperature fast black nickel water. Background technique [0002] The black nickel coating is black and has a strong extinction ability. It is often used in some industries with special requirements such as optical instruments and photographic equipment. The black nickel coating has a high absorption rate of solar energy and can be used for solar heat collectors. Recently, it has been on the rise in domestic decorative applications, especially in clocks, lamps, and leather accessories. The black nickel coating is relatively hard, with poor wear resistance and corrosion resistance, and the coating is directly coated with black nickel on steel parts, the bonding force between the coating and the substrate is poor, and the color will become lighter after polishing. Generally, a thinner black nickel layer (only about 2mm) is flash-plated o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D3/12

Inventor 梁纪元梁尹琦戴华玉李洪雷鑫胡常兰

Owner 东莞市宝中实业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com