Trivalent black chromium electroplating agent easy to prepare and preparation method thereof

A technology of electroplating agent and black chromium, which is applied in the field of trivalent black chromium electroplating agent and its preparation, can solve the problems of factors restricting the development of trivalent black chromium, uneven color plating of workpieces, narrow current density range, etc., and achieve simplified frequent analysis Chromium ion process, simplification of the process of adding chromium salt, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

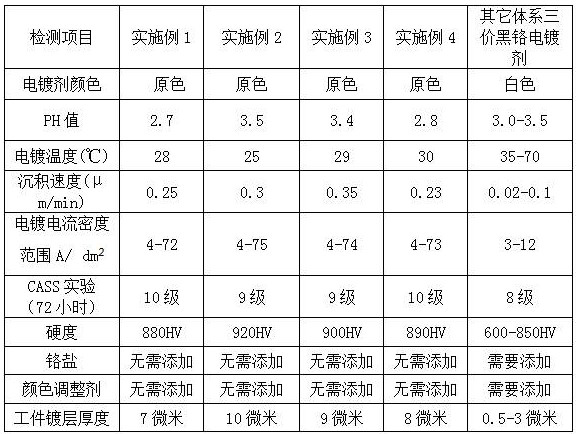

Examples

Embodiment 1

[0037] A trivalent black chromium electroplating agent with simple preparation, which is made from the following components in parts by weight:

[0038] Potassium chloride 25 parts,

[0039] 25 parts of ammonium chloride,

[0040] 25 parts of boric acid,

[0041] 20 parts of chromium trichloride,

[0042] Potassium thiocyanate 2.5 parts,

[0043] Methionine 2.5 parts.

[0044] In one embodiment, the methionine is a mixture of 2-amino-4-methylthiobutyric acid, DL-methionine, methionine and methionine.

[0045] The preparation process of this deployment simple trivalent black chromium electroplating agent: earlier carry out weighing and preparation respectively to potassium chloride, ammonium chloride, boric acid, chromium trichloride, potassium thiocyanate and methionine according to the above-mentioned parts; Potassium chloride, ammonium chloride and boric acid are put into the mixing kettle as main materials until the potassium chloride, ammonium chloride and boric acid ...

Embodiment 2

[0047] A trivalent black chromium electroplating agent with simple preparation, which is made from the following components in parts by weight:

[0048] Potassium chloride 18 parts,

[0049] 23 parts of ammonium chloride,

[0050] 35 parts of boric acid,

[0051] 23 parts of chromium trichloride,

[0052] Potassium thiocyanate 3 parts,

[0053] Methionine 4 parts.

[0054] In one of the embodiments, methionine uses 2-amino-4-methylthiobutyric acid, DL-methionine, methionine, methionine, DL-2-amino-4-methylthio One of butyric acid, DL-methionine, methionine and methionine.

[0055] The manufacturing process of this deployment simple trivalent black chromium electroplating agent: first according to the above-mentioned parts, potassium chloride, ammonium chloride, boric acid, chromium trichloride, potassium thiocyanate and methionine are weighed and prepared; secondly, the chlorine Potassium chloride, ammonium chloride and boric acid are put into the mixing kettle as the ma...

Embodiment 3

[0057] A trivalent black chromium electroplating agent with simple preparation, which is made from the following components in parts by weight:

[0058] Potassium chloride 15 parts,

[0059] 27 parts of ammonium chloride,

[0060] 33 parts of boric acid,

[0061] 19 parts of chromium trichloride,

[0062] Potassium thiocyanate 4 parts,

[0063] Methionine 3 parts.

[0064] In one embodiment, the methionine is a mixture of DL-2-amino-4-methylthiobutyric acid, DL-methionine, slewing methionine and methionine.

[0065] The manufacturing process of this deployment simple trivalent black chromium electroplating agent: first according to the above-mentioned parts, potassium chloride, ammonium chloride, boric acid, chromium trichloride, potassium thiocyanate and methionine are weighed and prepared; secondly, the chlorine Potassium chloride, ammonium chloride and boric acid are put into the mixing kettle as the main materials until the potassium chloride, ammonium chloride and bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com