High-temperature-resistant high-density solid-phase-free formate drilling fluid system

A high-density, solid-free technology, applied in the field of oil drilling, can solve problems such as the unsystematic development of solid-free drilling fluid systems, and achieve good reservoir protection performance, improved stability, and strong inhibitory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

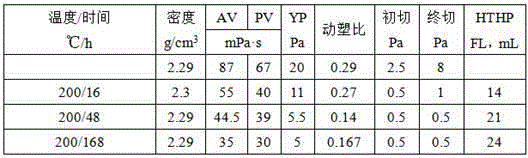

[0022] Embodiment 1 prepares a kind of density 2.30g / cm by the prescription of table 1 3 High-temperature resistant high-density solid-phase formate-free drilling fluid system and its performance test.

[0023] Table 1

[0024]

[0025] 1. Indoor preparation procedure

[0026] (1) According to the formula determined above, weigh various treatment agents; each preparation amount is 4*350ml or 8*350ml;

[0027] (2) During preparation, mix potassium formate and cesium formate in a high-speed shear mixer at a speed of 1500rpm for 10 minutes, then increase the speed to 6000rpm, and slowly add viscosifiers and fluid loss additives at intervals of 5 minutes , Graphite, Potassium Carbonate, Potassium Bicarbonate, Magnesium Oxide, Seawater, and Calcium Carbonate are added within the last 3 minutes. The entire preparation process ensures that all components are added within 45 minutes and mixed uniformly to obtain the product;

[0028] (3) The temperature during mixing shall not e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com