Washing method of screening type coarse slime sorting washbox

A technology of coarse coal slime and jigging machine, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of low separation density, easy fluctuation of product quality, and poor separation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

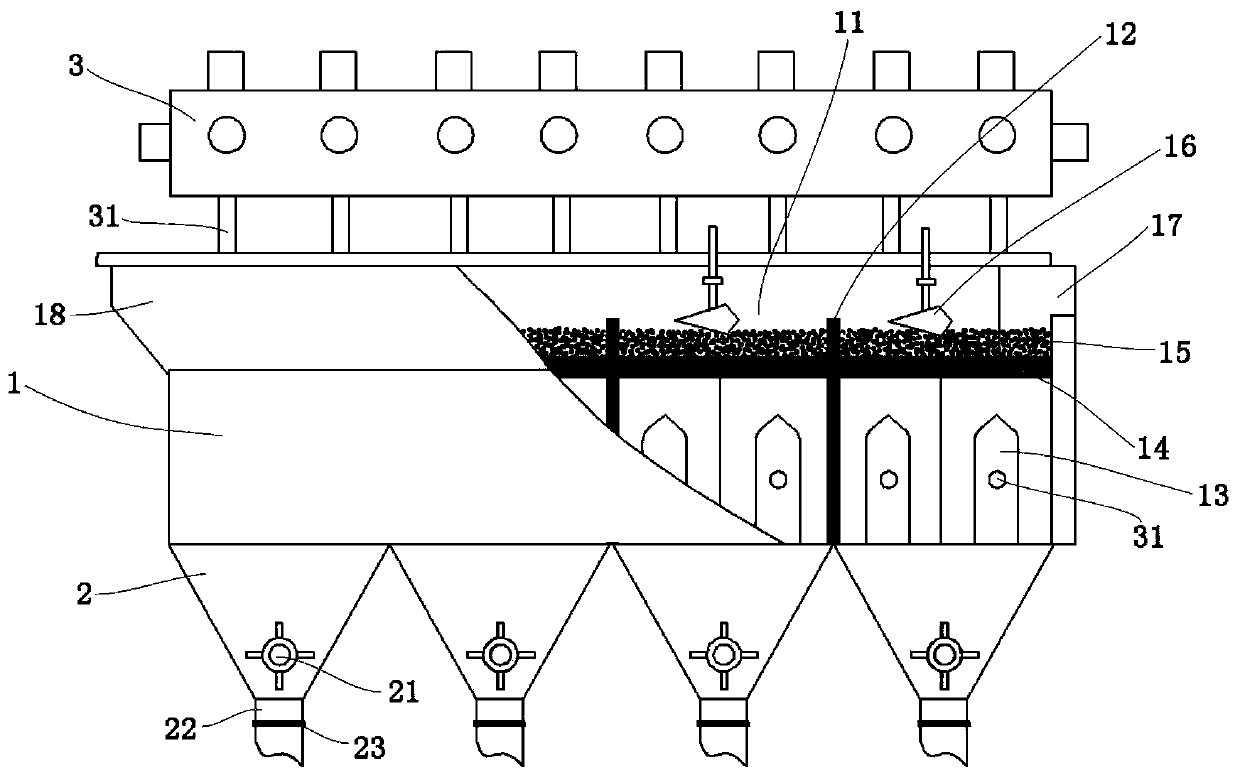

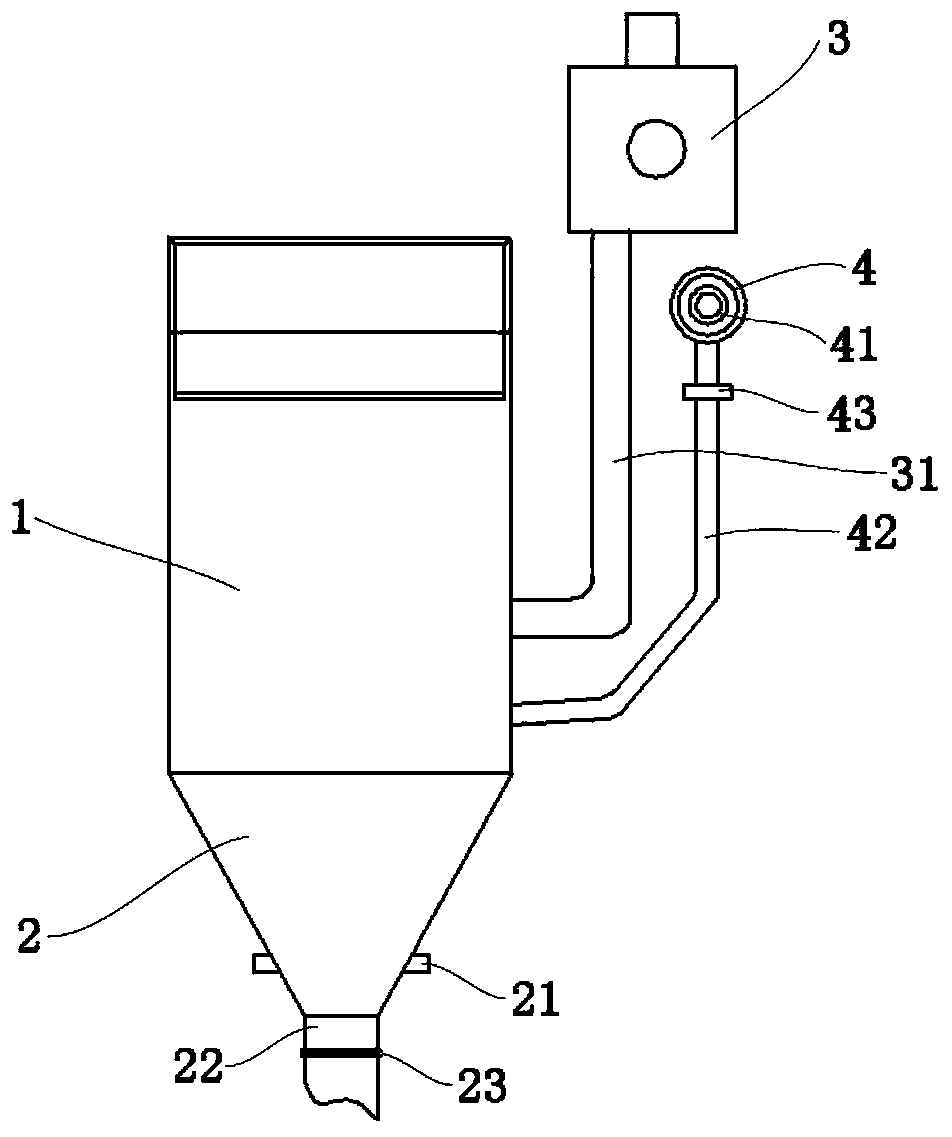

[0032] Please refer to figure 1 , figure 2 , the present embodiment provides a method for washing with a sieve-type coarse slime sorting jig machine, the method is realized by a sieve-type coarse slime sorting jig machine, and the sieve-type coarse slime separation The jigging machine comprises an upper body 1, a lower body 2, a numerical control bellows 3 and a main water pipe 4; the upper body 1 is a cuboid, including a partition 12, an air chamber 13, a sieve plate 14, an artificial bed 15, and a buoy 16; The board 12 divides the upper body 1 into compartments 11, the upper body is divided into four compartments 11 along the length direction, each compartment has two chambers, and each chamber contains an air chamber 13, and the air chamber 13 is arranged on the upper body 1. At the inner bottom, the sieve plate 14 is arranged on the upper end of the air chamber 13 without an inclination angle. The artificial bed 15 can creep stably on the sieve plate 14 without cross-li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com