Emulsifying and flushing spacer fluid for improving cementing quality of oil-based drilling fluid and preparation method of emulsifying and flushing spacer fluid

A technology of oil-based drilling fluid and flushing spacer fluid, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of inability to efficiently remove filter cake on the wellbore wall, unable to meet the needs of cementing, and single role of spacer fluid, etc. problems, achieve good interface flushing and wetting reversal capabilities, improve displacement efficiency, and solve the effects of high-temperature flushing performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

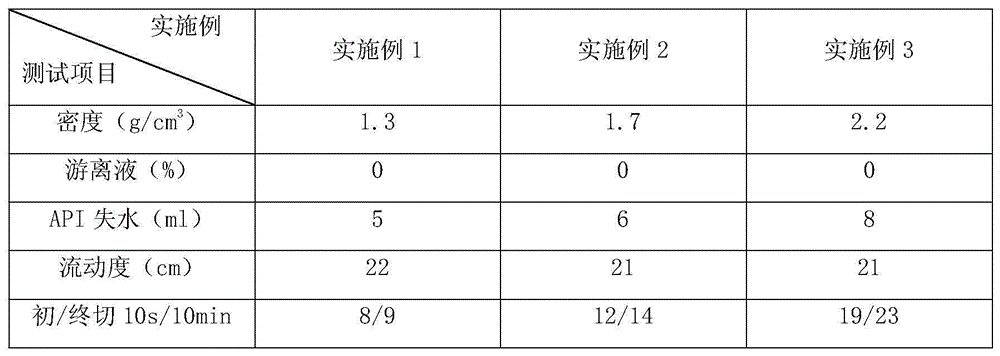

Embodiment 1

[0029] Put 100 parts of water in the slurry cup, add 5-10 parts of surfactant, add 0.05 parts of sodium carboxymethyl cellulose, stir at 8000r / min for 10min, then add 70-75 parts of base oil, and then add 8000r / min Stir for 5 minutes at a speed of / min to form an emulsion; put 100 parts of water in another slurry cup, add 8 parts of sodium bentonite, and stir for 3 hours; then add 0.6 parts of sodium humate, 0.5 parts of sodium carboxymethyl cellulose, and 0.5 1 part of sodium sulfomethyl gallate, stir evenly to adjust the performance to meet the requirements, and then put in 90 parts of barite powder; mix the above two solutions, add 0.05 part of tributyl phosphate and stir for 1 hour to obtain an emulsified flushing isolation solution with a density of 1.3g / cm3 .

Embodiment 2

[0031] Put 100 parts of water in the slurry cup, add 5-10 parts of surfactant, add 0.05 parts of sodium carboxymethyl cellulose, stir at 8000r / min for 10min, then add 70-75 parts of base oil, and then add 8000r / min / min speed and stir for 5 minutes to form an emulsion; put 100 parts of water in another slurry cup, add 10 parts of sodium bentonite, and stir for 3 hours; then add 2.0 parts of sodium humate, 1.3 parts of sodium carboxymethyl cellulose, 2.5 1 part of sodium sulfomethyl gallate, stir evenly to adjust the performance to meet the requirements, and then put 220 parts of barite powder; mix the above two solutions, add 0.05 part of tributyl phosphate and stir for 1 hour to obtain an emulsified flushing isolation solution with a density of 1.7g / cm3 .

Embodiment 3

[0033] Put 100 parts of water in the slurry cup, add 5-10 parts of surfactant, add 0.05 parts of sodium carboxymethyl cellulose, stir at 8000r / min for 10min, then add 70-75 parts of base oil, and then add 8000r / min / min speed and stir for 5 minutes to form an emulsion; put 100 parts of water in another slurry cup, add 15 parts of sodium bentonite, and stir for 3 hours; then add 3.0 parts of sodium humate, 1.5 parts of sodium carboxymethyl cellulose, 3.5 365 parts of barite powder after stirring evenly to adjust the performance to meet the requirements; mix the above two solutions, add 0.05 parts of tributyl phosphate and stir for 1 hour to obtain a density of 2.2g / cm 3 Emulsified flushing isolation fluid.

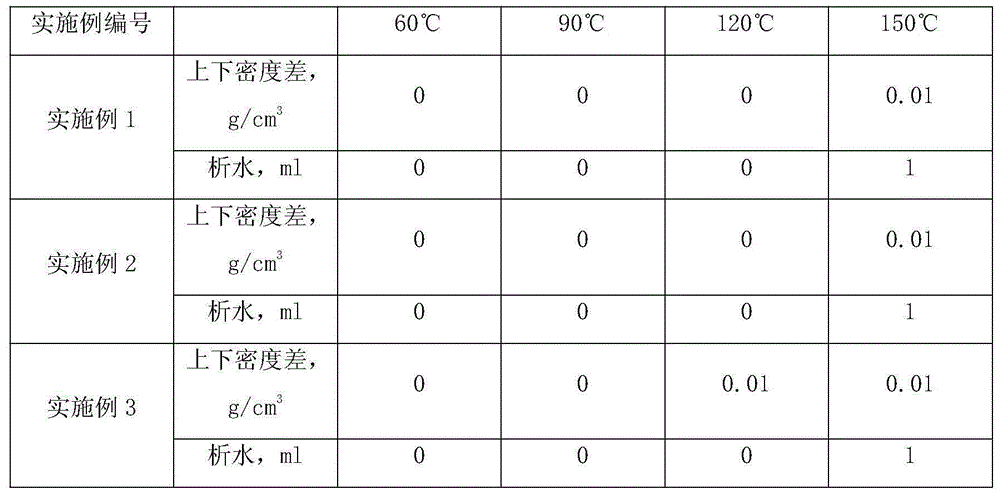

[0034] 2. Performance test of emulsified flushing spacer fluid to improve the cementing quality of oil-based drilling fluid

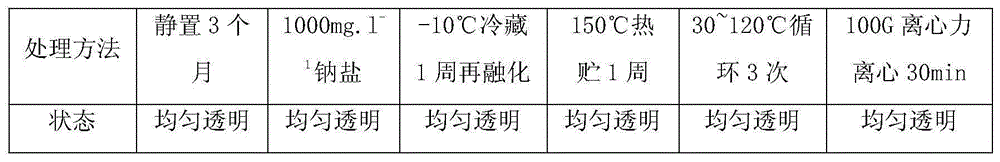

[0035] (1) Stability test of emulsion:

[0036] The preparation method of the emulsion is: put 100 parts of water in the slurry cup, add 5 to 10 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com