High-performance water-based drilling fluid suitable for long horizontal section of shale gas, and preparation method thereof

A technology of water-based drilling fluid and horizontal sections, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problems of stability and lubricity of the borehole wall of extended-reach horizontal wells, and difficulties in guaranteeing the quality of oil sludge and cement cement , insufficient environmental performance of oil-based drilling fluids, etc., to achieve the effects of improving wellbore stability, improving drilling efficiency, and reducing water intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The invention provides a high-performance water-based drilling fluid suitable for a long horizontal section of shale gas and a preparation method thereof:

[0037] Measure 300ml of produced water, add 2.1g of loose bentonite powder under high-speed stirring (10000r / min), stir for 20min, then add 2.1g of caustic soda, stir for 20min; then add 3.0g of nano silica, 1.5g of nano Graphite, stir for 20min; then add 2.1g low-viscosity polyanionic cellulose, stir for 20min; add 0.3g cationic polyacrylamide, stir for 20min; then add 6g sulfonated asphalt potassium salt, stir for 20min; add 3g oxidized asphalt, 3g Sulfomethyl brown coal resin, stir for 10min; 9g aminosilanol, stir for 10min; 9g styrene-acrylic latex, stir for 10min; 9g polyether polyol, stir for 10min, and finally add 560g barite (density 1.50g / cm 3 ) Stir for 20 minutes to obtain the product.

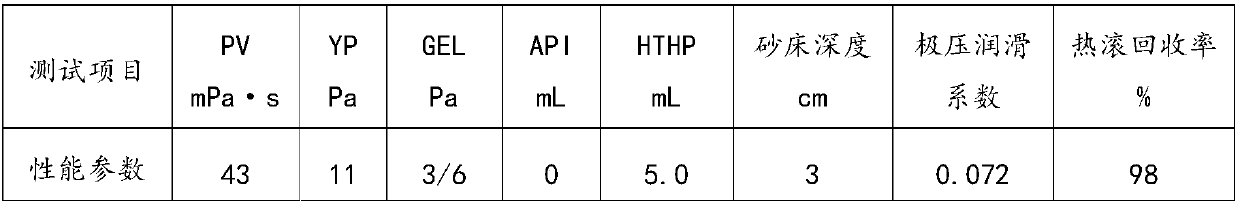

[0038] The performance of the product in this example is shown in Table 1. The parameters are measured at room temperature. ...

Embodiment 2

[0049] The invention provides a high-performance water-based drilling fluid suitable for a long horizontal section of shale gas and a preparation method thereof:

[0050] Measure 300ml of produced water, add 2.1g of loose bentonite powder under high-speed stirring (10000r / min), stir for 20min, then add 2.1g of caustic soda, stir for 20min; then add 3.0g sodium methyl silicate, 1.5g Nano graphite, stir for 20min; then add 2.1g carboxymethyl starch, stir for 20min; then add 0.3g anionic polyacrylamide, stir for 20min; then add 6g rubber latex modified emulsified asphalt, stir for 20min; then add 3g graphene oxide, 3g sulfomethyl phenolic resin, stirred for 10min; 9g amino-terminated polyether, stirred for 10min; 9g styrene latex, stirred for 10min; 9g polycaprolactone polyol, stirred for 10min, and finally added 560g barite (density 1.50g / cm 3 ) Stir for 20 minutes to obtain the product.

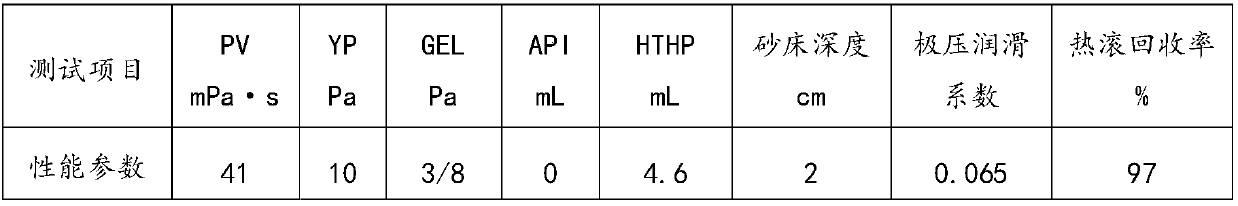

[0051] The performance of the product in this example is shown in Table 2, and the meaning of...

Embodiment 3

[0056] The invention provides a high-performance water-based drilling fluid suitable for a long horizontal section of shale gas and a preparation method thereof:

[0057] Measure 300ml of produced water, add 2.1g of loose bentonite powder under high-speed stirring (10000r / min), stir for 20min, then add 2.1g of caustic soda, stir for 20min; then add 3.0g sodium methyl silicate, 1.5g Nano graphite, stir for 20min; then add 2.1g of low-viscosity carboxymethylcellulose sodium salt and stir for 20min; add 0.3g of non-ionic polyacrylamide and stir for 20min; then add 6g of polystyrene modified asphalt and stir for 20min; Add 3g sulfomethyl brown coal resin, 3g sulfomethyl phenolic resin and stir for 10min; 9g polyethylene glycol, stir for 10min; 9g nitrile latex, stir for 10min; 9g alkyl glycoside, stir for 10min, and finally add 560g barite ( Density 1.50g / cm 3 ) Stir for 20 minutes to obtain the product.

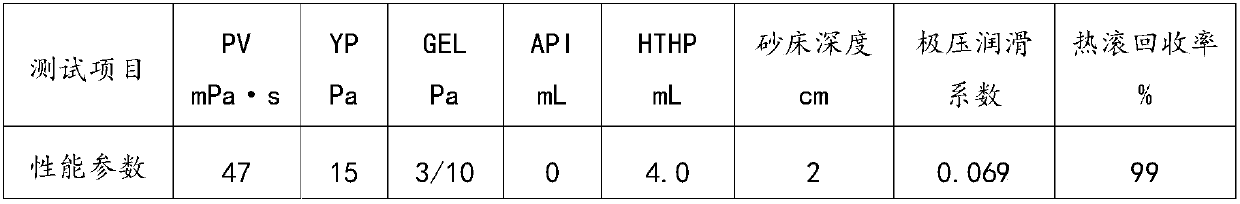

[0058] The performance of the product in this embodiment is shown in Table 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com