Liquid expanded graphite flame retardant and preparation method for flame-retardant polyurethane foam material

A technology of polyurethane foam and expanded graphite, which is applied in the field of liquid flame retardants, can solve problems such as application limitations, achieve a wide range of densities, be beneficial to environmental protection, and avoid the effects of viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

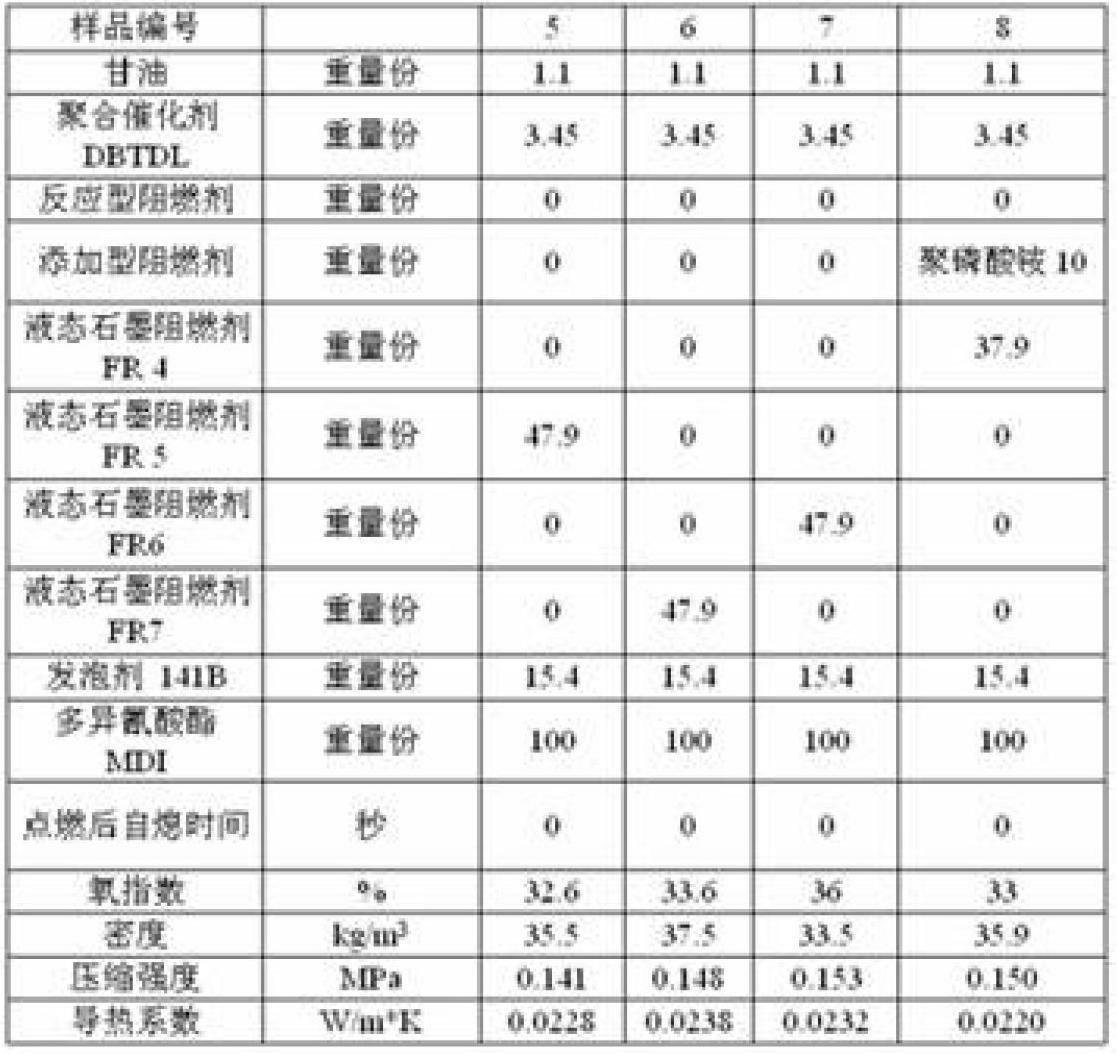

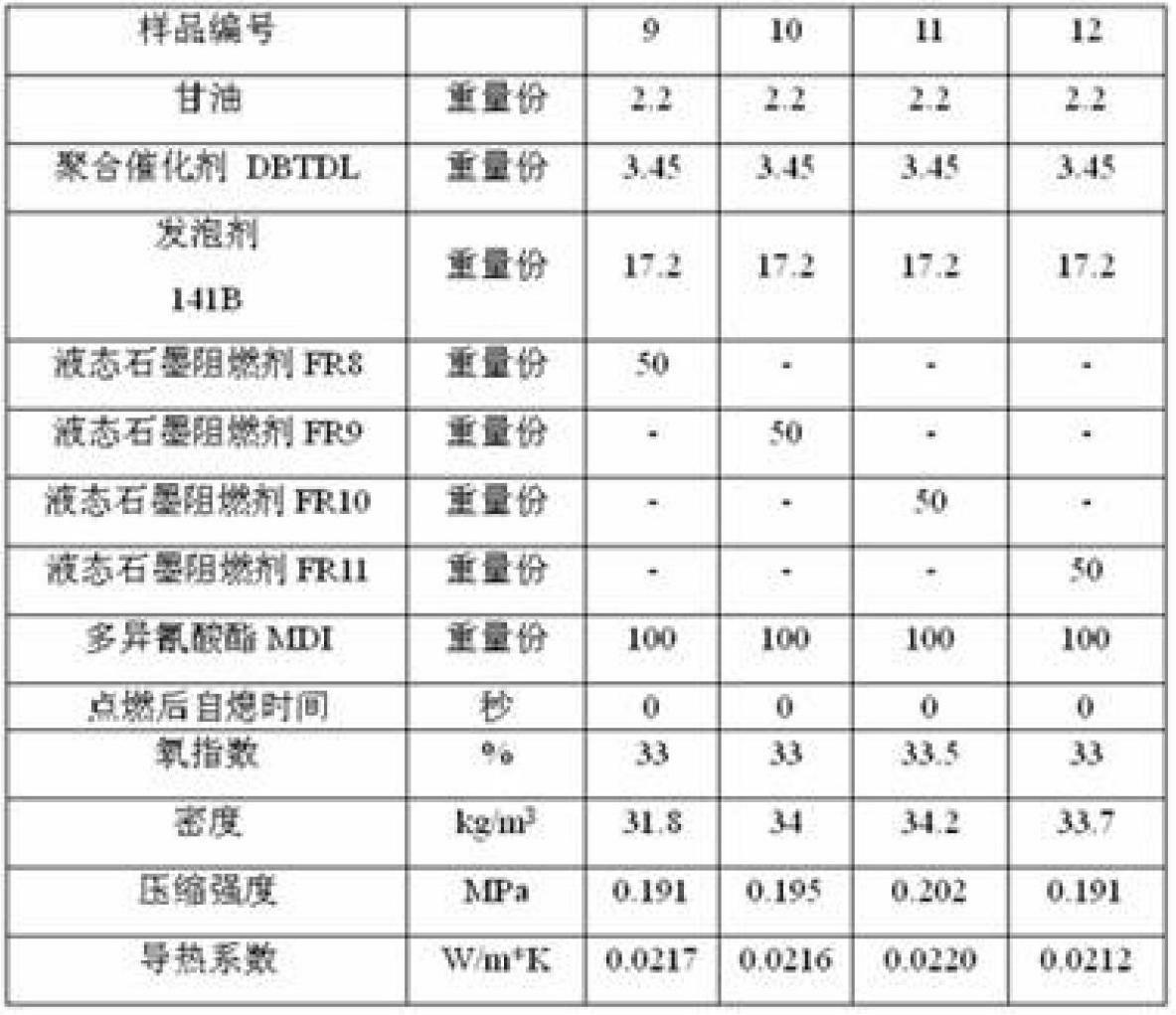

Examples

Embodiment 1

[0057] This example includes 3 production examples based on expanded graphite liquid flame retardant and 3 application examples, wherein the application example is a production example based on liquid graphite flame-retardant polyurethane foam material, and also includes 1 comparative production example of flame-retardant polyurethane foam material. Usually, the preparation of the liquid flame retardant and polyurethane foam is carried out at normal temperature, but the present invention also includes the preparation of the above products at a state higher than normal temperature.

manufacture example 1

[0059] Into a three-neck flask with an electric stirrer was added 20 grams of polyether polyol Arcol 3601, 10 grams of polyether polyol Arcol 1011, 0.4 grams of additives (alkylammonium salts of high molecular weight interpolymers) 9076, 20 grams of dimethyl methyl phosphate and 50 grams of exfoliated expandable graphite 100. After mixing the materials uniformly at normal temperature, the expanded graphite-based liquid flame retardant FR1 is obtained.

manufacture example 2

[0061] Into a three-necked flask with an electric stirrer, add 20 grams of polyether polyol VORANOL 360, 10 grams of polyether polyol Arcol 1011, 1.0 grams of additives (alkyl ammonium salt of high molecular weight interpolymer) 9077, 30 grams of dimethyl methyl phosphate and 40 grams of exfoliated expandable graphite 300. After mixing the materials uniformly at normal temperature, the expanded graphite-based liquid flame retardant FR 2 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com