Surfactant for drilling fluid and preparation method of surfactant

A surfactant and drilling fluid technology, applied in the field of petroleum drilling aids, can solve the problems of no guidance plan, complicated production process, and land environmental pollution, and achieve the reduction of downhole complex accidents, simplified process steps, and low circulation density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

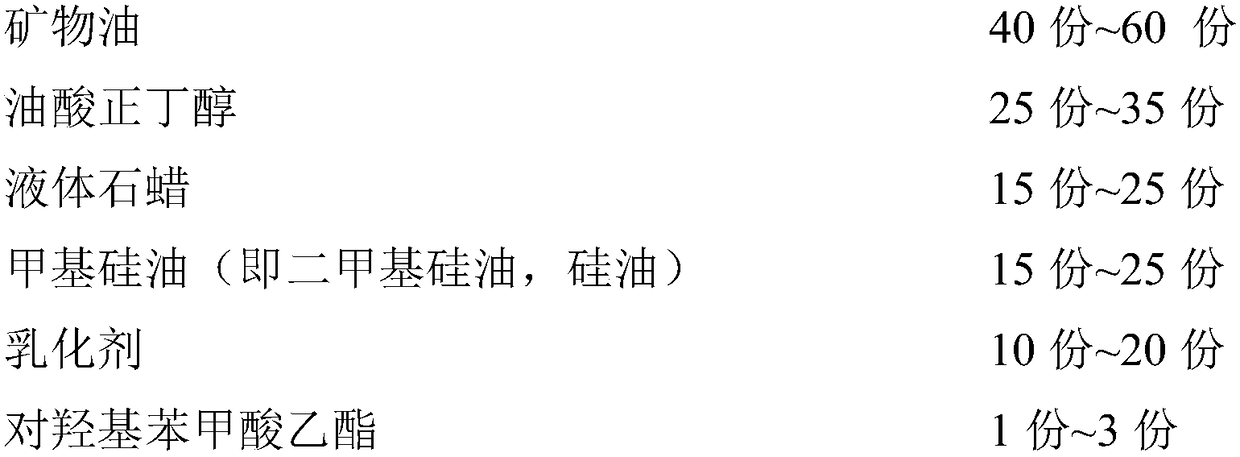

[0028]Embodiment 1: the tensio-active agent for drilling fluid of the present invention is made from the raw material of following weight ratio (weight parts, mass parts):

[0029]

[0030] Described mineral oil is the composition of No. 5 white oil, No. 7 white oil two kinds of raw materials, and the weight ratio of No. 5 white oil and No. 7 white oil is 1: 0.5; Described emulsifier is Tween T- 60. The composition of Tween T-80, the weight ratio of Tween T-60 to Tween T-80 is 1:2.

[0031] The preparation method of described surfactant for drilling fluid comprises following processing steps: 1. take by weighing raw material mineral oil (being No. 5 white oil, No. 7 white oil), oleic acid n-butanol, liquid paraffin, Methyl silicone oil, emulsifier (ie Tween T-60, Tween T-80), put each raw material into the reaction kettle, mix each raw material fully to obtain a mixture; ②Then emulsify the mixture, the emulsification temperature 60°C, the emulsification time is 2h, and the...

Embodiment 2

[0032] Embodiment 2: the tensio-active agent for drilling fluid of the present invention is made from the raw material of following weight ratio (weight parts, mass parts):

[0033]

[0034] Described mineral oil is No. 7 white oil; Described emulsifier is the composition of Tween T-80, emulsifier S-80, and the weight ratio of Tween T-80 and emulsifier S-80 is 1: 0.5.

[0035] The preparation method of described surfactant for drilling fluid comprises following processing steps: 1. take by weighing raw material mineral oil, oleic acid n-butyl alcohol, liquid paraffin, methyl silicone oil, emulsifying agent (being Tween T- 80. Emulsifier S-80), put each raw material into the reaction kettle, fully mix each raw material to obtain a mixture; ②Then emulsify the mixture, the emulsification temperature is 70 ° C, the emulsification time is 1.5h, the emulsification process After the process is completed, the intermediate product is obtained; ③ cool down the intermediate product o...

Embodiment 3

[0036] Embodiment 3: the tensio-active agent for drilling fluid of the present invention is made from the raw material of following weight ratio (weight parts, mass parts):

[0037]

[0038] Described mineral oil is No. 5 white oil; Described emulsifier is emulsifier S-80.

[0039] The preparation method of the described surfactant for drilling fluid comprises the following process steps: 1. Weigh the raw materials mineral oil, oleic acid n-butanol, liquid paraffin, methyl silicone oil and emulsifier according to the above weight ratio, and add each raw material to the reaction In the kettle, the raw materials are fully mixed to obtain the mixture; ②Then the mixture is emulsified, the emulsification temperature is 80 ° C, the emulsification time is 1h, and the intermediate product is obtained after the emulsification process is completed; ③ The intermediate product obtained in step ② Cool down, add 1 part of ethyl p-hydroxybenzoate at 50°C, make it fully mixed, and discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com