Lubrication inhibitor nanometer ester-group hydrate used for drilling fluid and preparation method thereof

A technology of ester hydrates and inhibitors, which is applied in the preparation of nano-ester hydrates of lubrication inhibitors for drilling fluids, and in the field of nano-ester hydrates of lubrication inhibitors for drilling fluids. Environmental pollution, raw materials are not easy to degrade and other problems, to achieve the effect of inhibiting hydration dispersion, simple preparation process, and reducing complex accidents downhole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

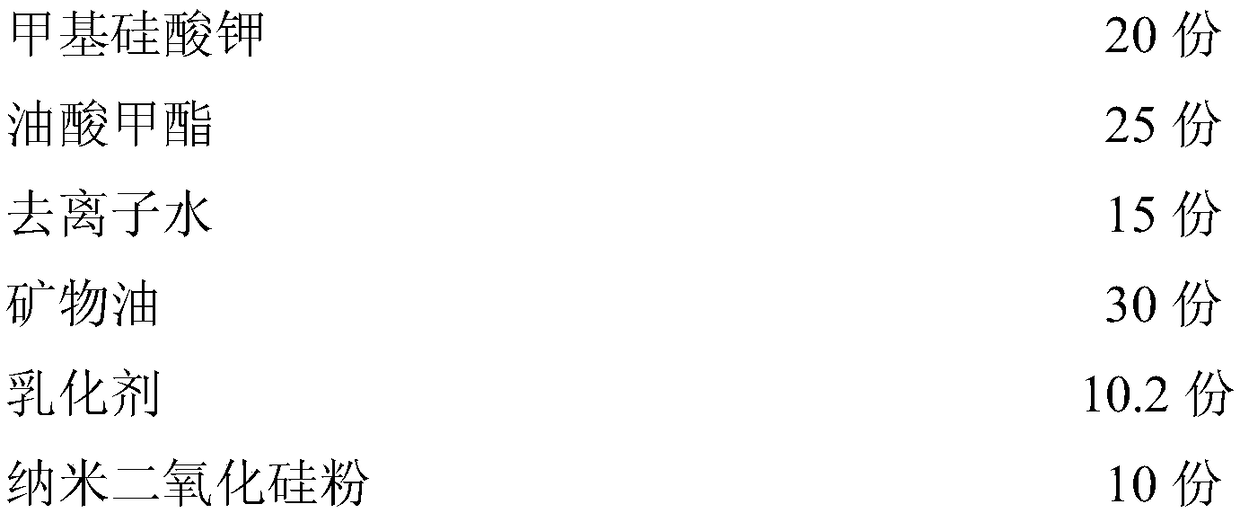

[0025] Embodiment 1: the nanometer ester hydrate of lubrication inhibitor for drilling fluid of the present invention is made from the raw material of following weight ratio (weight parts, mass parts):

[0026]

[0027]The emulsifier is a combination of polyoxyethylene sorbitan monooleate and sorbitan monooleate, polyoxyethylene sorbitan monooleate, sorbitan monooleate The weight ratio of the acid ester is 2:1; the mineral oil is a combination of No. 5 white oil and No. 7 white oil, and the weight ratio of No. 5 white oil and No. 7 white oil is 1:2.

[0028] The preparation method of the described lubrication inhibitor nano-ester-based hydrate for drilling fluid comprises the following process steps: ①Weigh the raw materials potassium methyl silicate, methyl oleate, deionized water, 10 parts of No. 5 White oil, 20 parts of No. 7 white oil, 6.8 parts of polyoxyethylene sorbitan monooleate, 3.4 parts of sorbitan monooleate, each raw material is added in the reaction kettle, a...

Embodiment 2

[0029] Embodiment 2: the nanometer ester hydrate of lubrication inhibitor for drilling fluid of the present invention is made from the raw material of following weight ratio (weight parts, mass parts):

[0030]

[0031] The emulsifier is a combination of polyoxyethylene sorbitan monooleate and sorbitan monooleate, polyoxyethylene sorbitan monooleate, sorbitan monooleate The weight ratio of the esters is 1:2; the mineral oil is No. 5 white oil.

[0032] The preparation method of the described lubrication inhibitor nano-ester-based hydrate for drilling fluid comprises the following process steps: ① Weigh the raw materials potassium methyl silicate, methyl oleate, deionized water, mineral oil, 2.7 1 part of polyoxyethylene sorbitan monooleate, 5.4 parts of sorbitan monooleate, each raw material is added in the reactor, makes each raw material fully mix and dissolve, obtains the mixture; ②Then emulsify the mixture process, the emulsification temperature is 75°C, the emulsifica...

Embodiment 3

[0033] Embodiment 3: the nanometer ester hydrate of lubrication inhibitor for drilling fluid of the present invention is made from the raw material of following weight ratio (weight parts, mass parts):

[0034]

[0035] Described emulsifier is polyoxyethylene sorbitan monooleate, and described mineral oil is No. 7 white oil.

[0036] The preparation method of the described lubrication inhibitor nano-ester-based hydrate for drilling fluid comprises the following process steps: ① Weigh the raw materials potassium methyl silicate, methyl oleate, deionized water, mineral oil, emulsified Add the raw materials into the reaction kettle to fully mix and dissolve the raw materials to obtain the mixture; ②Then carry out the emulsification process on the mixture, the emulsification temperature is 85°C, the emulsification time is 1h, and the intermediate product is obtained after the emulsification process is completed; ③ Cool down the intermediate product obtained in step ②, add 10 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com