Nano lubricant for drilling fluid as well as preparation method and application of nano lubricant

A lubricant and drilling fluid technology, applied in the field of nano-lubricant for drilling fluid and its preparation, can solve the problems of inapplicability, high temperature resistance, poor lubricating performance effect, etc., so as to reduce frictional resistance, improve high temperature resistance, and improve Effects of Dispersion and Stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example provides a kind of preparation method of nano-lubricant for drilling fluid, specifically comprises the following steps: 2 Add 25 g of sodium 2-acrylamide-2-methylpropanesulfonate and 5 g of vinyl tetrafluoroacetate (mass ratio: 5:1) to the three-necked flask at the entrance, add 175 mL of water and N,N-dimethylformethane The mixed solvent of amides (wherein water content is 94wt%), mixing and stirring 5min; N 2 Under a gas atmosphere, add ammonium persulfate to it, whose mass accounts for 0.5wt% of the total amount of monomers, then heat up to 94°C and react at a constant temperature for 5 hours, then cool to room temperature, and add 2.5 times of volume of ethanol, fully stirred and then filtered, and then the filtrate was vacuum-dried at 60° C. for 8 hours to obtain a nano-lubricant for drilling fluid (product purity: 97%).

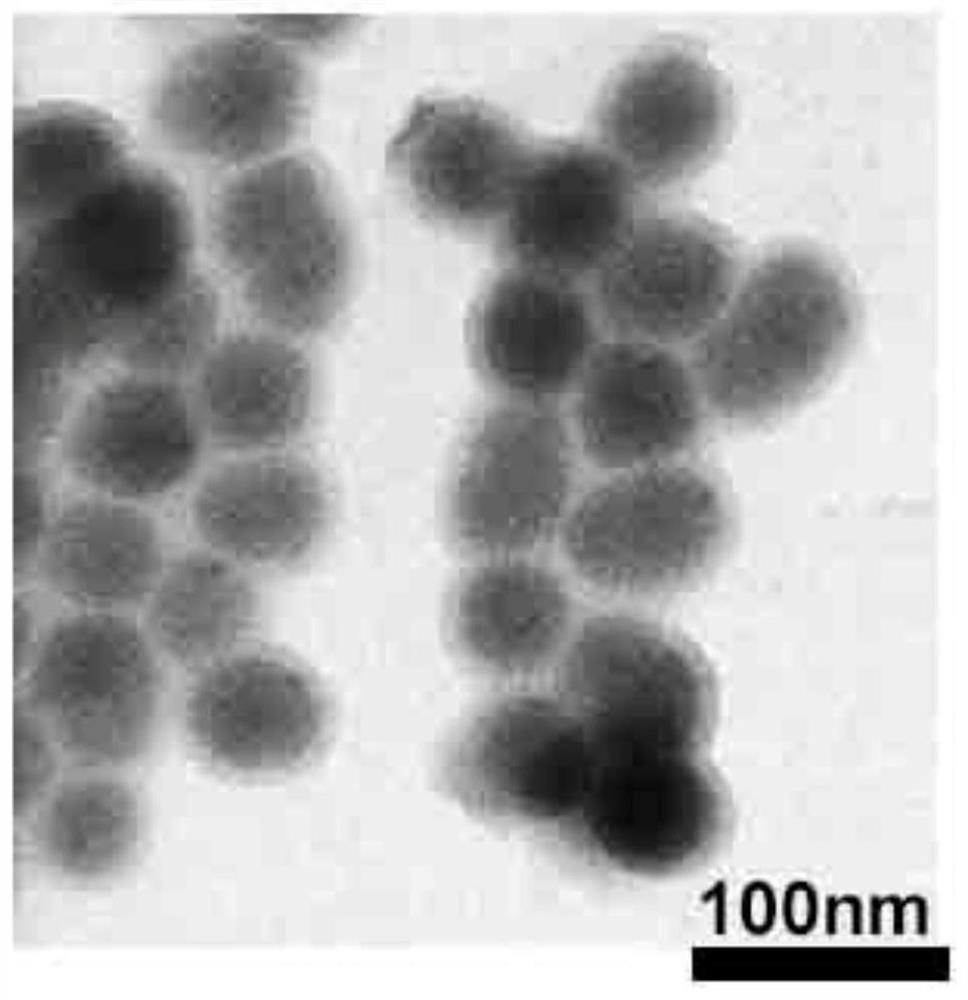

[0030] The TEM image of the nano-lubricant used in drilling fluid made in this example is as follows figure 1 shown by figure 1 ...

Embodiment 2

[0032] This example provides a kind of preparation method of nano-lubricant for drilling fluid, specifically comprises the following steps: 2 Add 23g of sodium vinylsulfonate and 2.3g of trifluoroethyl acrylate (mass ratio is 10:1) successively in the three-necked bottle of entrance, add the mixed solvent of 180mL water and N-methylpyrrolidone (wherein water content is 95wt% ), mixed and stirred for 5min; N 2 Under the gas atmosphere, add ammonium persulfate thereinto, its mass accounts for 1.5wt% of the total amount of monomers, start to heat up to 85°C and react at a constant temperature for 3h, then cool to room temperature, add 2.3 times to the mixed solution obtained after the reaction is completed volume of ethanol, fully stirred and then filtered, and then the filtrate was vacuum-dried at 50° C. for 8 hours to obtain a nano-lubricant for drilling fluid (product purity: 95%).

Embodiment 3

[0034] This example provides a kind of preparation method of nano-lubricant for drilling fluid, specifically comprises the following steps: 2 Add 30 g of sodium styrene sulfonate and 2 g of propylene trifluoroacetate (15:1 in mass ratio) successively in the three-necked flask at the entrance, and add 275 mL of a mixed solvent of water and dimethyl sulfoxide (wherein the water content is 96 wt %) Mix and stir for 5min; N 2 Under the atmosphere of gas, add ammonium persulfate thereinto, its mass accounts for 2wt% of monomer total amount, begin to heat up to 80 ℃ and constant temperature reaction 4h after cooling to room temperature, add 2.8 times of volume to the mixed solution obtained after the reaction is completed ethanol, fully stirred and filtered, and then the filtrate was vacuum-dried at 74° C. for 10 hours to obtain a nano-lubricant for drilling fluid (product purity: 98%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com