Automatic mixed gas filtering device

A technology of automatic filtration and gas mixing, applied in the direction of mobile filter element filter, filtration separation, separation method, etc., can solve the problems of low quality, paint overflow, inconvenient cleaning, etc., achieve fast filtration speed, low lubrication coefficient, Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

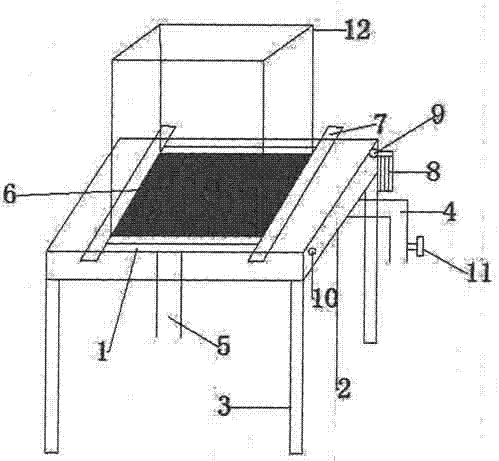

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and examples of implementation.

[0015] As shown in the figure, a mixed gas automatic filtering device provided by the present invention includes a filter tank (1), a support frame (2), a support (3), a discharge pipe (4) and an impurity output pipe (5), and the support (3) is fixedly installed with the filter trough (1) that is made up of support frame (2), and the filter trough (1) top is provided with the filter frame (7) with filter net (6), and motor (8) passes bolt (9) ) is connected to the support frame (2), the vibration button (10) is installed on the left side of the support frame (2), the feeding cylinder (12) is installed on the filter frame (7), and the outlet pipe (4) is equipped with an adjustable outlet Liquid speed and a regulating valve (11) with switch control function.

[0016] When the present invention is in use, the pain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com