Emulsified asphalt for drilling fluids

A technology of emulsified asphalt and drilling fluid, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor anti-slump lubrication, inconvenient transportation, storage and use, poor temperature resistance, etc., and achieve temperature resistance Improvement, good anti-slump lubrication, improved temperature resistance and anti-coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

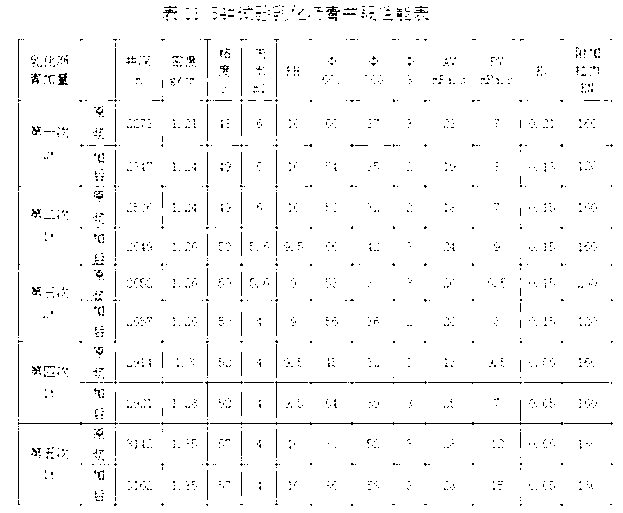

Embodiment 1

[0027] A kind of emulsified asphalt for drilling fluid, the raw material is composed of the following substances according to the mass percentage: the density is 0.98 g / cm 3 80% of petroleum asphalt,

[0028] Extreme pressure lubricating oil 5%, dispersant IW 1%, fluorocarbon FC-3b 1%, polyether 330N 1%, diesel oil 10%, polyethylene glycol 1%, glycidyltrimethylammonium chloride 1% . The water content of petroleum asphalt is less than 2%.

[0029] The preparation method is: fully stir and mix at room temperature, and then emulsify through a colloid mill.

[0030] The water content of petroleum asphalt is less than 2%.

[0031] The extreme pressure lubricating oil is composed of fatty acid methyl ester and oleic acid methyl ester, the mass content of fatty acid methyl ester is 80%, and the mass fraction of oleic acid methyl ester is 20%.

Embodiment 2

[0033] A kind of emulsified asphalt for drilling fluid, the raw material is composed of the following substances according to the mass percentage: the density is 0.98 g / cm 3 75% of petroleum asphalt,

[0034] Extreme pressure lubricating oil 10%, dispersant IW 1%, fluorocarbon FC-3b 1%, polyether 330N 1%, diesel oil 10%, polyethylene glycol 1%, glycidyltrimethylammonium chloride 1% . The water content of petroleum asphalt is less than 2%.

[0035] The preparation method is: fully stir and mix at room temperature, and then emulsify through a colloid mill.

[0036] The water content of petroleum asphalt is less than 2%.

[0037] The extreme pressure lubricating oil is composed of fatty acid methyl ester and oleic acid methyl ester, the mass content of fatty acid methyl ester is 80%, and the mass fraction of oleic acid methyl ester is 20%.

Embodiment 3

[0039] A kind of emulsified asphalt for drilling fluid, the raw material is composed of the following substances according to the mass percentage: the density is 1.01 g / cm 3 76% of petroleum asphalt,

[0040] Extreme pressure lubricating oil 9%, dispersant IW 1%, fluorocarbon FC-3b 1%, polyether 330N 1%, diesel oil 10%, polyethylene glycol 1%, glycidyltrimethylammonium chloride 1% . The water content of petroleum asphalt is less than 2%.

[0041] The preparation method is: fully stir and mix at room temperature, and then emulsify through a colloid mill.

[0042] The water content of petroleum asphalt is less than 2%.

[0043] The extreme pressure lubricating oil is composed of fatty acid methyl ester and oleic acid methyl ester, the mass content of fatty acid methyl ester is 80%, and the mass fraction of oleic acid methyl ester is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com