Silica gel film plating windshield wiper rubber strip and preparation method thereof

A technology of silica gel and wiper, applied in the direction of coating, etc., can solve the problems of high friction coefficient, difficult and difficult surface of silica gel, etc., and achieve the effect of good anti-aging performance, low lubrication coefficient and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

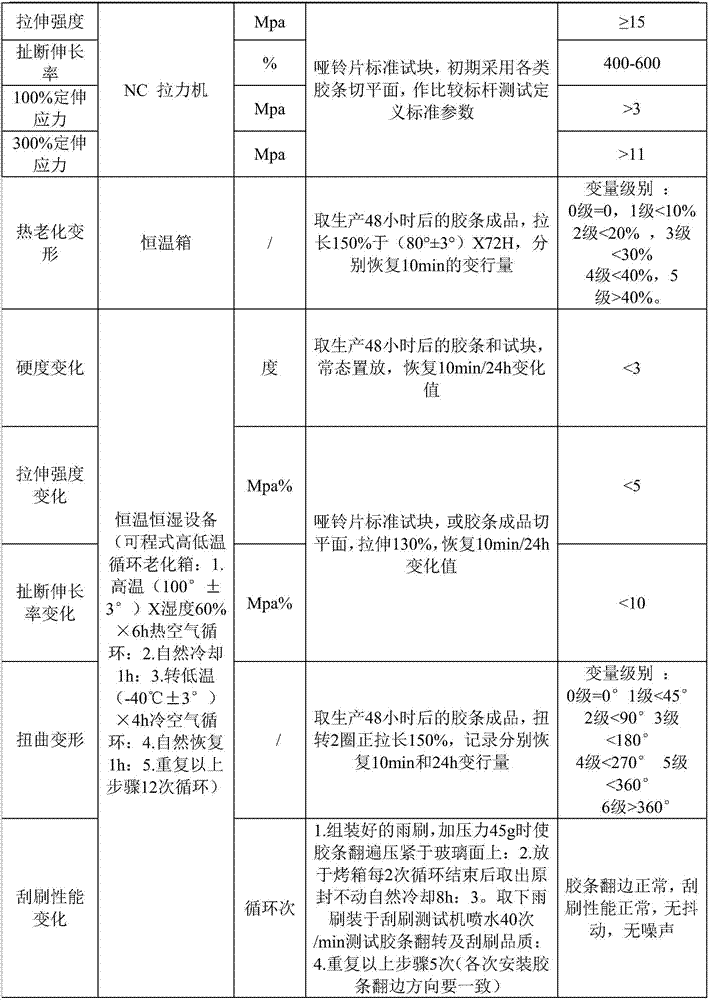

Examples

Embodiment 1

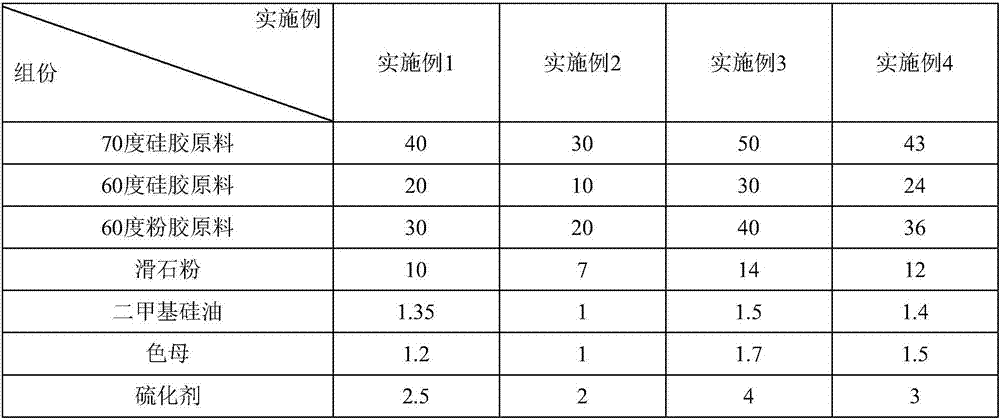

[0038] Take raw material according to table 1, preparation method is as follows:

[0039] Mixed rubber: first mix dimethyl silicone oil and 60-degree powder rubber raw materials in a 14-inch open mill to obtain masterbatch 1, then mix masterbatch 1 with talcum powder to obtain masterbatch 2, and then mix the masterbatch 1 Rubber 2 is mixed with 70-degree silica gel raw materials, 60-degree silica gel raw materials, color masterbatch and vulcanizing agent to obtain mixed rubber;

[0040] Vulcanization: Put the mixed rubber obtained in the previous step into the mold cavity, put it into a vulcanizer, the pressure is 300T, the temperature is 180°C, the vulcanization time is 300 seconds, and the vulcanized material is obtained;

[0041] Surface treatment: Put the vulcanized material obtained in the previous step into water at 80°C, add detergent and ultrasonically clean it for 3 minutes, dry it and bake it in a baking oven at 90°C for 5 minutes, and then use the pulse surface trea...

Embodiment 2

[0045] The raw materials are shown in Table 1, and the preparation method is the same as in Example 1 to prepare the silicone-coated wiper strip 2.

Embodiment 3

[0047] The raw materials are shown in Table 1, and the preparation method is the same as in Example 1 to prepare the silicone-coated wiper strip 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com