Gel breaking solution and use thereof

A technology of glue and coagulant, which is applied in the field of glue breaking liquid, can solve the problems of nowhere to discharge waste low solid-phase polysulfonic drilling fluid, large particle size of broken colloid, environmental pollution, etc. Low cost of raw materials and the effect of reducing the overall cost of drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

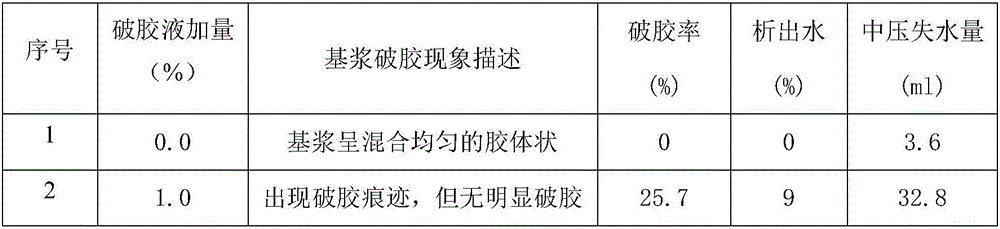

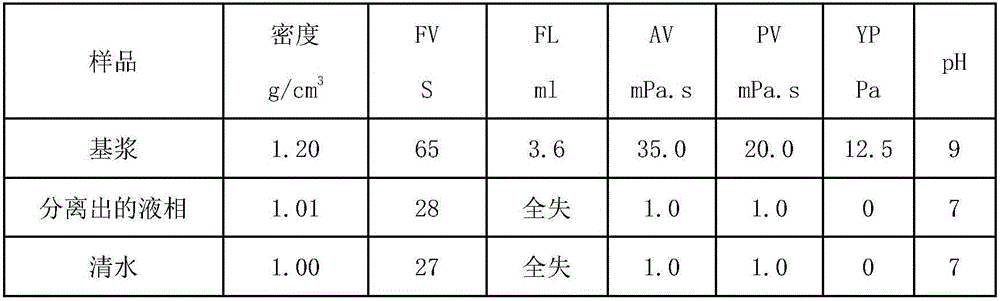

Examples

Embodiment 1

[0014] In order to overcome the problem of waste low-solid-phase polysulfonate drilling fluid nowhere to be discharged and environmental pollution after the drilling fluid "does not fall to the ground", the present invention proposes a gel breaking fluid, which includes the following components: by weight percentage, 10%- 30% coagulant, 1.0%-3.0% flocculant, 1.0%-5.0% solid-liquid separation agent, and the balance is water.

[0015] The gel breaking solution of the present invention is based on inorganic high molecular polymers, organic propylene-based copolymers, and modified cellulose polyamine salts. Toxic and biodegradable are environmentally friendly. It can break the glue and destabilize the abandoned low-solid polysulfonate drilling fluid glue-breaking formula of oil and gas wells in Changqing Oilfield, and realize solid-liquid separation by using the existing solid control system of the well team (no need to add additional equipment). The liquid technology is easy to ...

Embodiment 2

[0017] This embodiment provides a gel breaking solution, which comprises the following components by weight:

[0018] Coagulant: 20%

[0019] Flocculant: 2.5%

[0020] Solid-liquid separating agent: 3.0%

[0021] Water: 74.5%

[0022] Wherein, the coagulant is a mixture of polyaluminum sulfate and polyaluminum iron silicate, the weight ratio of polyaluminum sulfate and polyaluminum iron silicate is 3:2, both polyaluminum sulfate and polyaluminum iron silicate can be purchased in the market Purchase online, and polyaluminum sulfate is a high-quality product specified in the standard GB14591-93.

[0023] The flocculant is a copolymer of propylene oxide, ethylene oxide, and acrylamide, the weight ratio of propylene oxide, ethylene oxide, and acrylamide is 1:1:3, and the molecular weight of the copolymer is 10 million. The solid-liquid separating agent is carboxymethyl-propenyl-amino modified cellulose sodium salt, the copolymer of propylene oxide, ethylene oxide, acrylamide a...

Embodiment 3

[0058] This embodiment provides a gel breaking solution, which comprises the following components by weight:

[0059] Coagulant: 30%

[0060] Flocculant: 1.0%

[0061] Solid-liquid separating agent: 1.0%

[0062] Water: 68%

[0063] Wherein, the coagulant is a mixture of polyaluminum sulfate and polyaluminum iron silicate, the weight ratio of polyaluminum sulfate and polyaluminum iron silicate is 3:2, both polyaluminum sulfate and polyaluminum iron silicate can be purchased in the market Purchase online, and polyaluminum sulfate is a high-quality product specified in the standard GB14591-93.

[0064] The flocculant is a copolymer of propylene oxide, ethylene oxide, and acrylamide. The weight ratio of propylene oxide, ethylene oxide, and acrylamide is 1:1:3, and the molecular weight of the copolymer is 12 million. The solid-liquid separating agent is carboxymethyl-propenyl-amino modified cellulose sodium salt, the copolymer of propylene oxide, ethylene oxide, acrylamide and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com