Packer test device and use method

A test device and packer technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of high cost, unfavorable general adoption, large space occupation, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

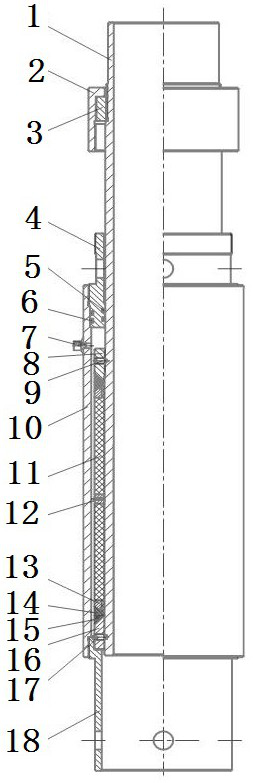

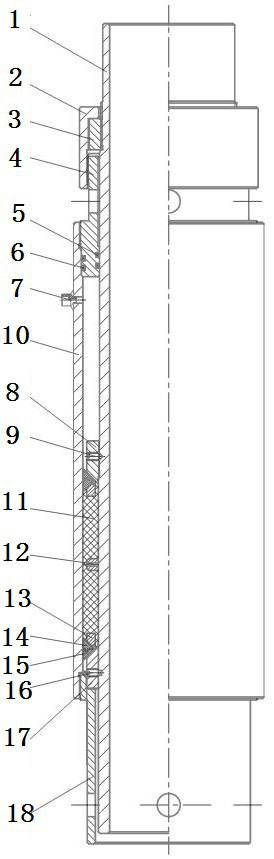

[0025] A packer test device, comprising a central pipe 1, a limit screw sleeve 2, a connecting screw sleeve 3, a sealing ring 4, a casing 10, an injection head 7, a push cylinder 18 and a packer, the packer includes a fixed screw Sleeve 8, rubber tube 11, spacer ring 12, pressure ring 13, male expansion ring 14, female expansion ring 15 and sliding sleeve 16, the fixed screw sleeve 8 is fixedly arranged in the middle of the central tube 1, at the center of the lower end of the fixed screw sleeve 8 The pipe 1 is provided with a female expansion ring 15, a male expansion ring 14, a compression ring 13, a rubber sleeve 11, a spacer ring 12, a rubber sleeve 11, a compression ring 13, a male expansion ring 14 and a female expansion ring 15 from top to bottom. The sliding sleeve 16 is fixed on the lower end of the central tube by the shear pin 17; the limit screw sleeve 2 is arranged on the upper part of the central tube 1, the sealing ring 4 is located between the limit screw sleeve...

Embodiment 2

[0035] This embodiment further illustrates the present invention in conjunction with the accompanying drawings.

[0036] Such as figure 1 As shown, a packer test device is composed of a central pipe 1, a limit screw sleeve 2, a connecting screw sleeve 3, a sealing ring 4, a casing 10, an injection head 7, a pusher 18 and a packer. The device consists of a fixed screw sleeve 8, a rubber cylinder 11, a spacer ring 12, a pressure ring 13, a male expansion ring 14, a female expansion ring 15 and a sliding sleeve 16 and the like. Described fixed screw sleeve 8 is installed in the middle part of center tube 1 by thread, and the lower end is male taper, and is fixed with pin 9, then on central tube 1 and the lower end of fixed screw sleeve 8, female expansion ring 15, male expansion ring are installed successively. Ring 14, pressure ring 13, rubber cylinder 11, spacer ring 12, rubber cylinder 11, pressure ring 13, male expansion ring 14, female expansion ring 15 and sliding sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com