A stepless drag fracturing process in casing and fracturing tool string

A tool string and stepless technology, which is applied in the direction of casing, drill pipe, wellbore/well components, etc., can solve the problems of easily polluted formations, complicated procedures, and long time consumption, and achieve short construction time and small liquid pumping volume , The effect of reducing construction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

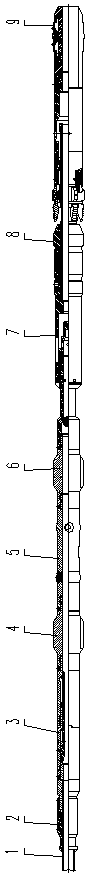

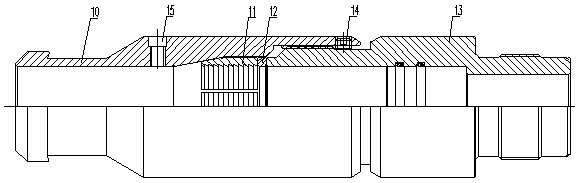

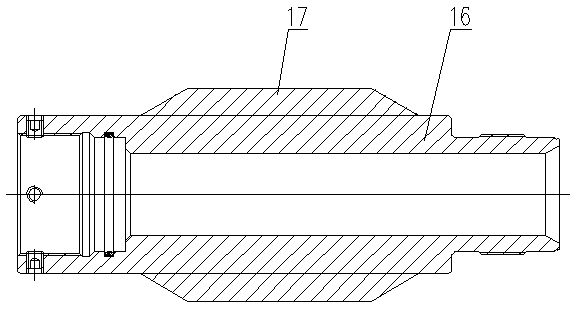

[0058] The fracturing tool string is connected to the coiled tubing 1 through the outer slip connector 2, and lowered into the section to be reformed of the oil and gas well at a constant speed. The fracturing tool string is connected by the outer slip connector 2 and hydraulic safety joint 3 in sequence , rigid centralizer A4, hydraulic sandblasting tool 5, rigid centralizer B6, reverse circulation valve 7, compression packer 8 and collar positioner 9; The rigid centralizer A4, rigid centralizer B6 and the slips on the compression packer 8 keep the entire fracturing tool string at the center of the casing, so as to reduce the frictional resistance between the fracturing tool string and the inner wall of the casing and make the fracturing tool string The fracturing tool string goes into the well smoothly; and the bottom hole position is found through the coupling positioner 9 on the fracturing tool string.

[0059] The outer slip connector 2 of the fracturing tool string is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com