Edge computing method, medium and system for rotating equipment monitoring

A technology of rotating equipment and edge computing, which is applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as network transmission costs and information integrity, and achieve the effect of reducing data transmission volume and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

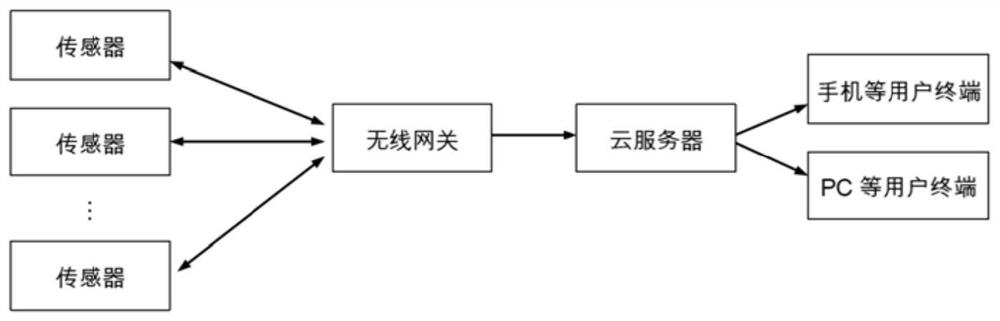

[0046] Rotating equipment monitoring system embodiment:

[0047] Such as figure 1 As shown, the rotating equipment monitoring system includes a sensor that collects the vibration signal of the centrifugal pump, an edge computing unit (not shown in the figure) and a cloud server installed inside the sensor. The edge computing unit preprocesses the vibration signal and obtains the characteristic The data is transmitted to the cloud server through the wireless gateway. The cloud server analyzes the received characteristic data to obtain the specific fault diagnosis results of the centrifugal pump, and then transmits the specific fault diagnosis results to the user terminal, and the user can view the centrifugal pump fault diagnosis results on the terminal.

[0048] The preprocessing process of the edge computing unit in this embodiment includes the following steps:

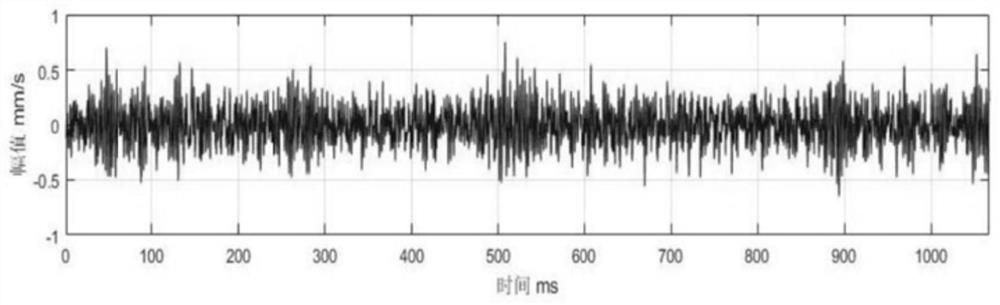

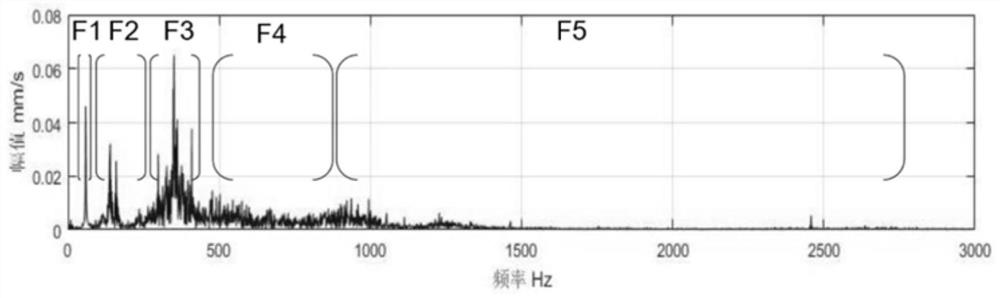

[0049] 1) According to the acquired vibration signal f(t) of the centrifugal pump, such as figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com