Setting method, device and system for trimming width of cold rolled strip steel

A technology for cold-rolling strip steel and setting methods, which is applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., and can solve problems such as misoperation, frequent manual setting operations, and inaccurate strip trimming width values , to achieve the effect of ensuring accuracy, reducing manpower and material resources, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

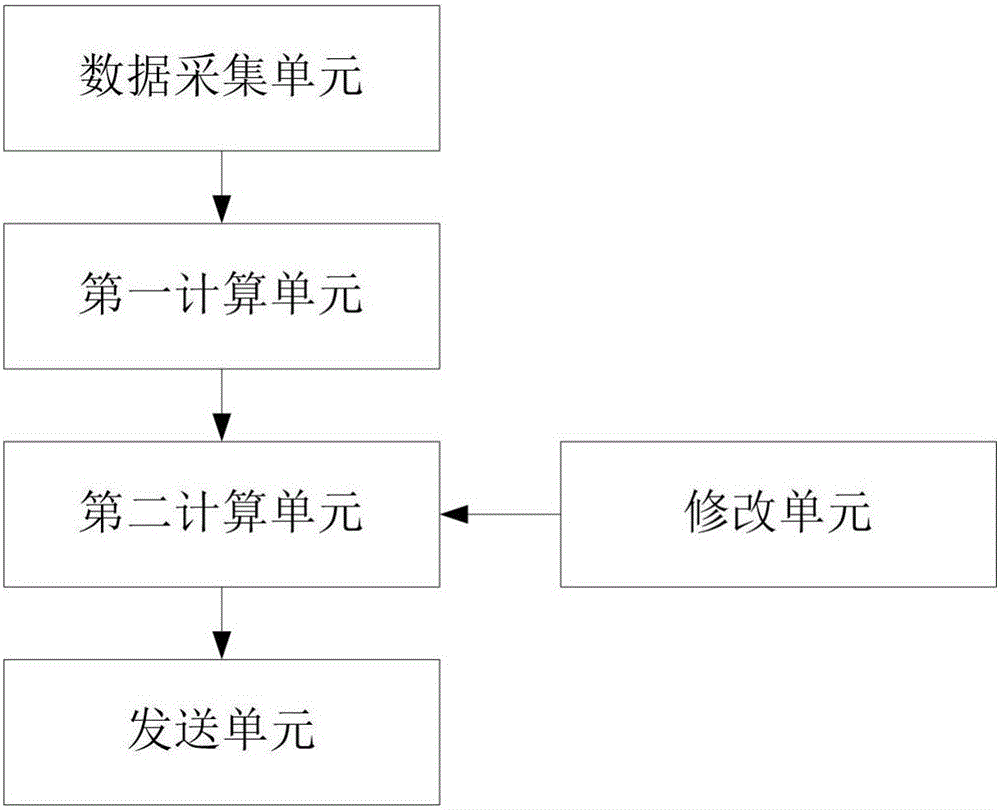

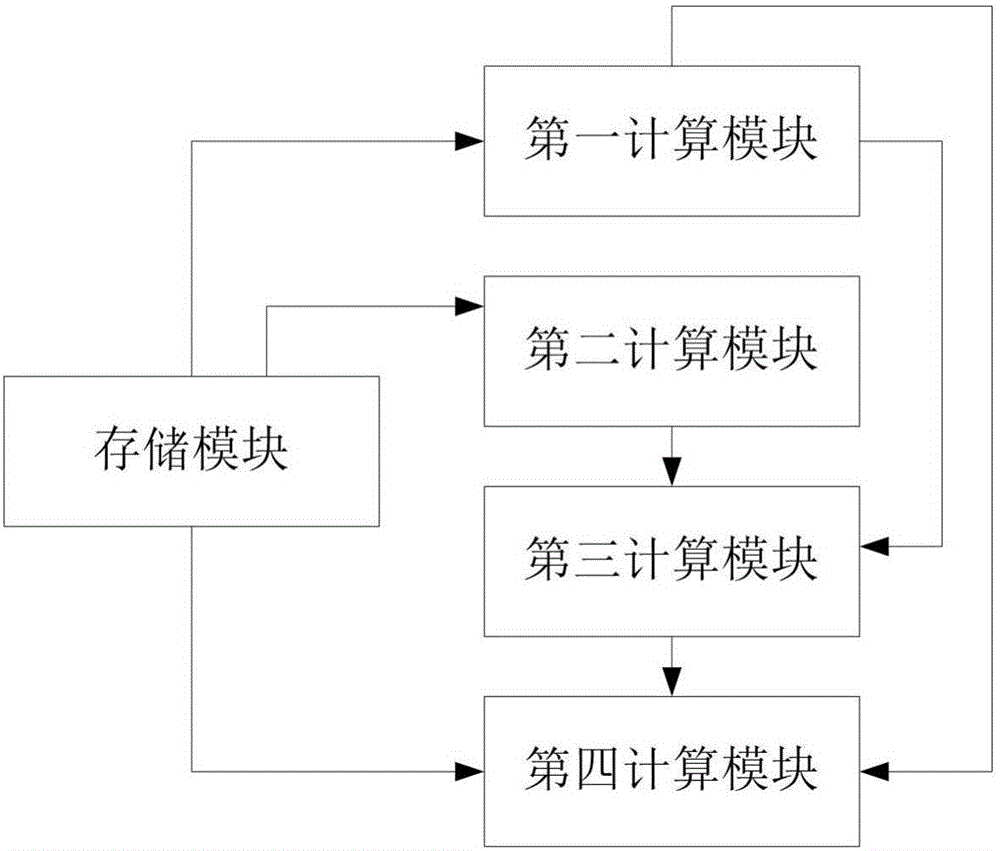

[0050] The embodiment of the present invention provides a method, device and system for setting the trimming width of cold-rolled strip steel, which solves the problem that the value of the trimming width of the strip steel manually set in the prior art is inaccurate, the manual setting operation is frequent, and it is easy to cause The technical problem of misoperation realizes the automatic calculation and setting of the trimming width of cold-rolled strip steel, improves the accuracy of the setting value of trimming width of cold-rolled strip steel, and reduces a lot of manpower and material resources.

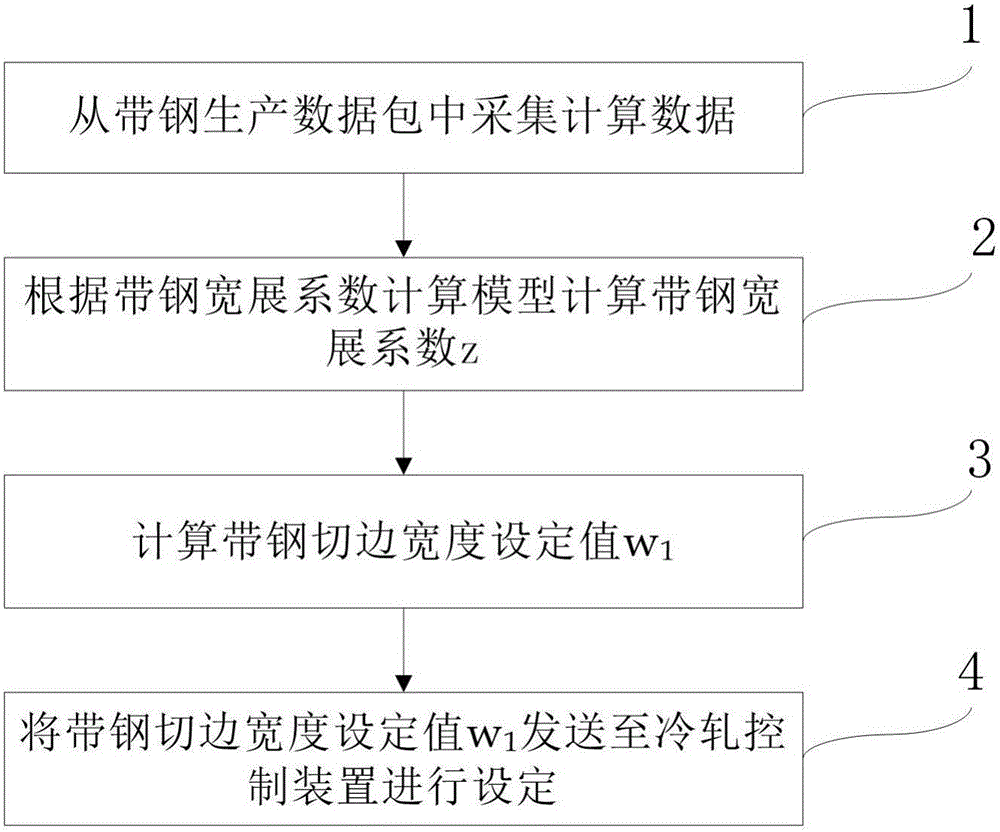

[0051] see figure 1 , the embodiment of the present invention provides a method for setting the trimming width of cold-rolled strip steel, the method is proposed for the same type of steel, and the method includes the following steps:

[0052] Step 1. Collect calculation data from the strip steel production data package.

[0053] Calculation data include: strip raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com