Precise epoxy injector

An injection machine and epoxy technology, which is applied in the field of injection machines, can solve the problems of unsatisfactory product performance, low degree of automation, and low proportioning precision, so as to improve the degree of intelligent operation and control accuracy, and broaden the application and market Foreground, the effect of high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

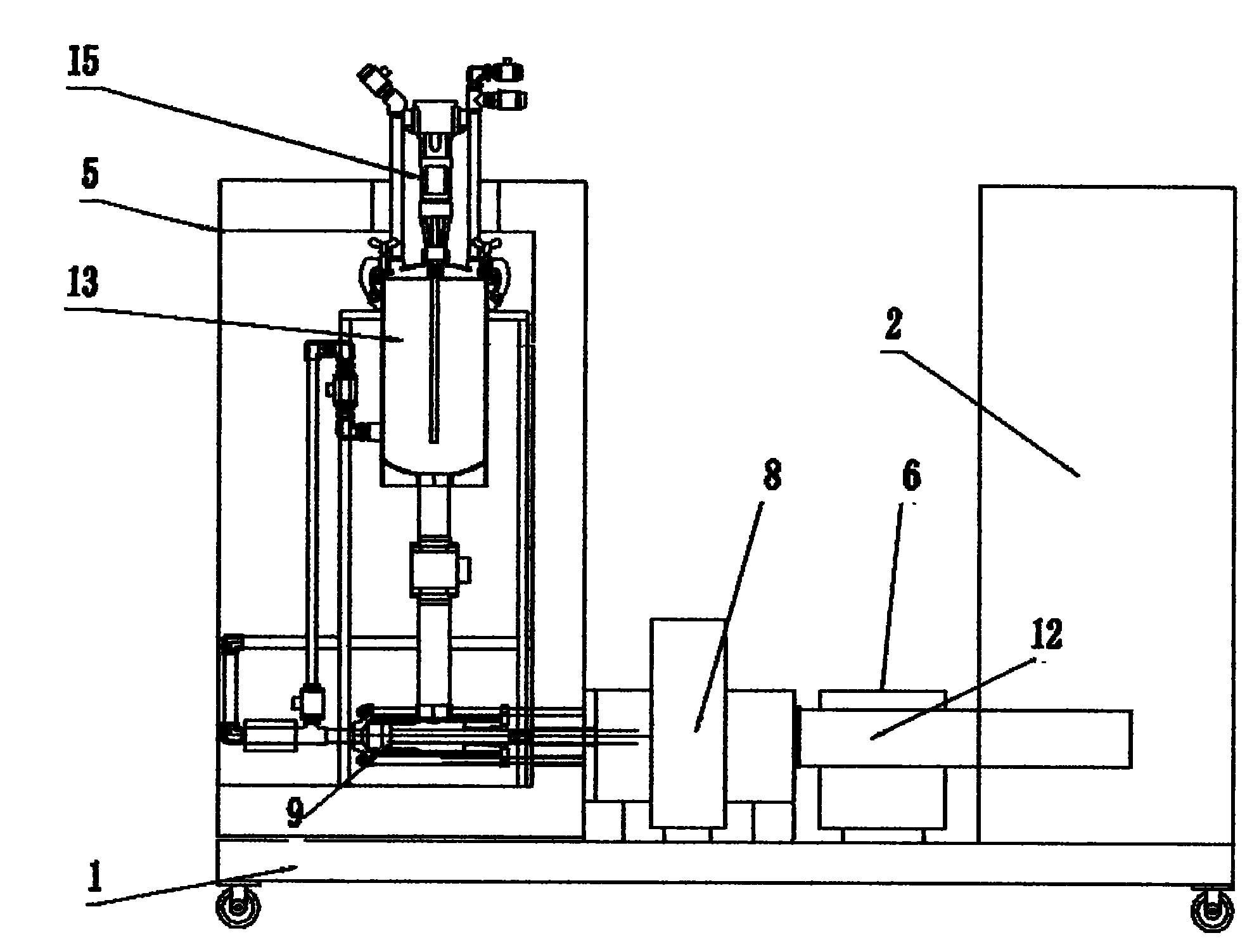

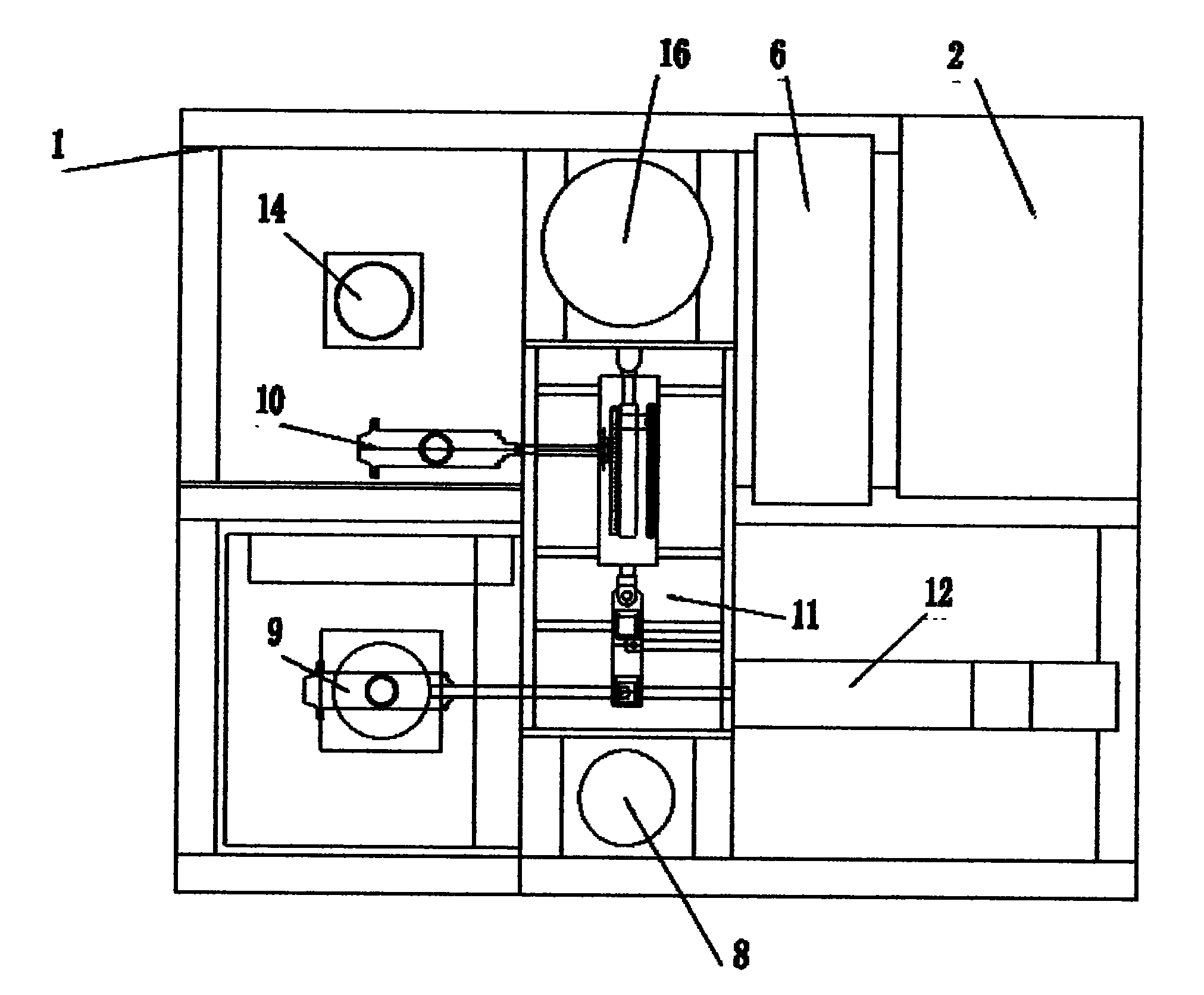

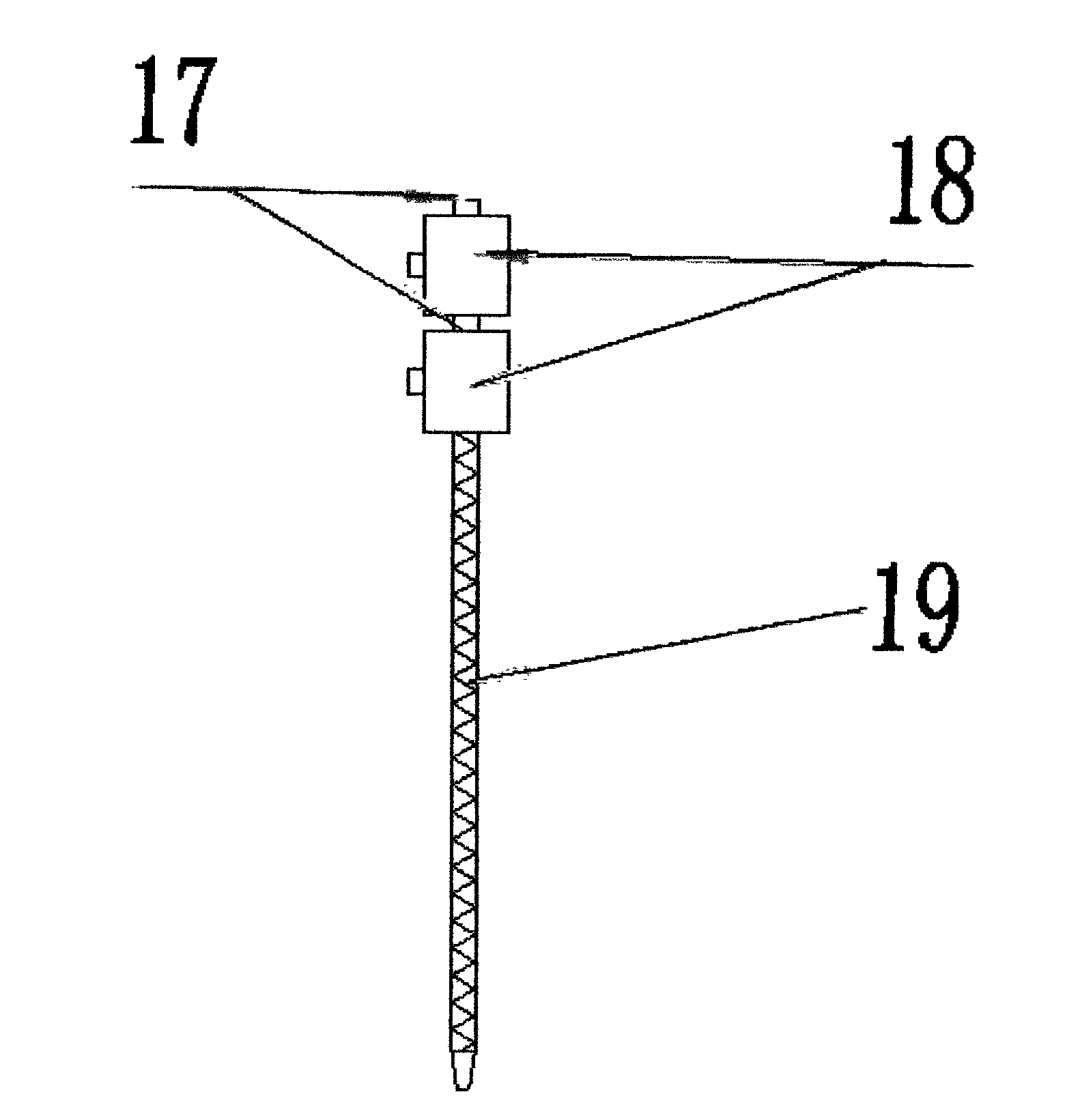

[0015] Such as Figure 1~3 As shown, a precision epoxy injection machine of the present invention includes a frame body 1, a control system 2 located on the frame body 1, a raw material processing system, a heating system 5, a material feeding backflow system, a mixing system, a cleaning system 8 and a vacuum pump 6. The control system 2 is connected to the raw material processing system, the heating system 5, the feeding backflow system, the mixing system, the cleaning system 8 and the vacuum pump 6 respectively, and the raw material processing system is connected to the heating system 5 and the feeding backflow system respectively, The feeding and reflux system is connected to a mixing system, and the mixing system is connected to a cleaning system 8 ; the raw material processing system is connected to a vacuum pump 6 .

[0016] The raw material processing system includes a resin tank 13 and a curing agent tank 14, a buffer tank 16 connected to the resin tank 13 and the curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com