No-residue release mechanism

A release mechanism and no residue technology, which is applied in the field of workover, oil production in oil and gas fields, and downhole tools, can solve the problems of prolonging the grinding and milling time and increasing the difficulty of grinding and milling, so as to reduce the grinding and milling time and avoid the effect of bridge plug falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0038] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

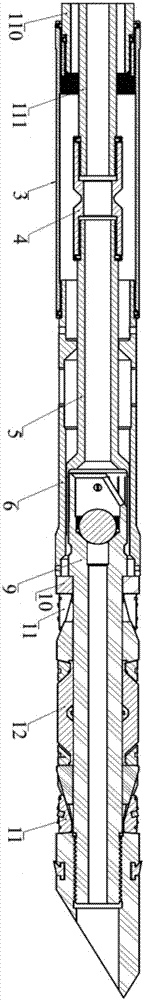

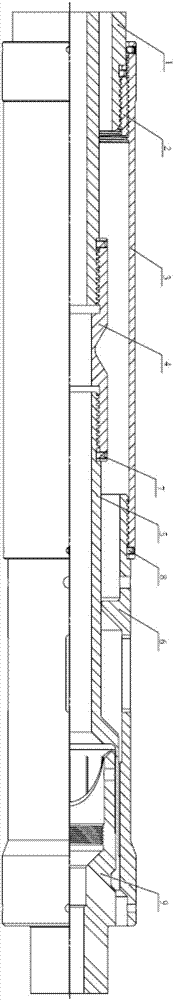

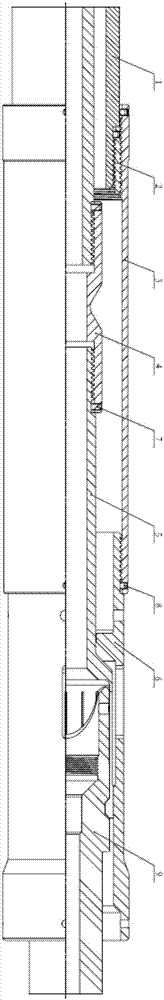

[0039] The present invention provides a residue-free release mechanism such as figure 1 shown, including:

[0040] The outer cylinder, one end of which presses the lifting shoulder on the outer surface of the bridge plug, and the other end is connected with the outer cylinder 110 of the setting tool 1;

[0041] The inner cylinder 5 is arranged in the outer cylinder and is slidably connected with the outer cylinder, and one end of the inner cylinder 5 is engaged with one end of the bridge plug; as a preferred method, the One end of the inner cylinder 5 has claws, and the claws a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com