Preparation method of casting box sealing paste

A technology of mud paste and fine mud, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of easy mildew and deterioration of grease, poor plasticity, short storage period, etc., and achieve good sealing effect and improved yield. , the effect of high refractoriness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

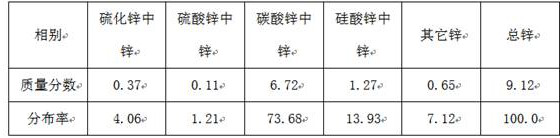

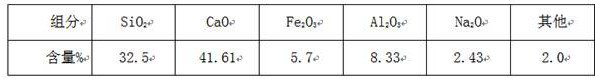

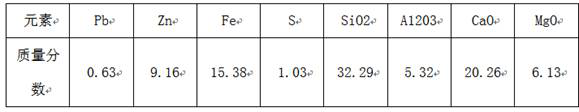

[0020] The first step, configure the cementing agent: add clear water, fine mud containing zinc oxide and polyphosphoric acid, in parts by weight: 33 parts of polyphosphoric acid, 20 parts of clear water, and 18 parts of fine mud containing zinc oxide into the container , heated, the temperature is controlled at 60°C, stirred for 40 minutes, taken out after it becomes a transparent colloid, cooled to room temperature, formed into a gelling agent, and set aside;

[0021] The second step, preparation of mixed powder: by parts by weight: 28 parts of red mud, 36 parts of magnesite, 20 parts of serpentine powder, 15 parts of dolomite powder, 4 parts of olivine sand, and 14 parts of salt-resistant soil are added to Stir in a blender for 8 minutes, mix well, and get mixed powder, set aside;

[0022] The third step, by weight: 45 parts of gelling agent and 70 parts of mixed powder are added to the mixer and stirred for 5 minutes, then 4 parts of plasticizer by mass fraction are added,...

Embodiment 2

[0031] The first step, configure the cementing agent: add clear water, fine mud containing zinc oxide and polyphosphoric acid, in parts by weight: 37 parts of polyphosphoric acid, 25 parts of clear water, and 18 parts of fine mud containing zinc oxide into the container , heated, the temperature is controlled at 60°C, stirred for 20-40 minutes, taken out after becoming a transparent colloid, cooled to normal temperature, formed into a gelling agent, and set aside; the second step, preparing the mixed powder: counted by parts by weight: red 28 parts of mud, 36 parts of magnesite, 20 parts of serpentine powder, 15 parts of dolomite powder, 4 parts of olivine sand, and 14 parts of salt-resistant soil were added to the mixer in turn and stirred for 8 minutes, mixed evenly to obtain mixed powder, and set aside; Three steps, calculated by weight: 45 parts of gelling agent and 70 parts of mixed powder are added to the mixer and stirred for 5 minutes, then 4 parts of plasticizer by mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com