Manufacturing method of carbon fiber composite material part mold

A technology of composite materials and manufacturing methods, which is applied in the field of manufacturing carbon fiber composite parts and molds, can solve the problems of unknowability, long manufacturing cycle, and complicated manufacturing process, and achieve the goals of shortening the manufacturing cycle, improving the quality of the parts, and reducing the manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A method for manufacturing a carbon fiber composite part mold, the specific steps of which are as follows:

[0039] 1. Manufacture of mold surface part:

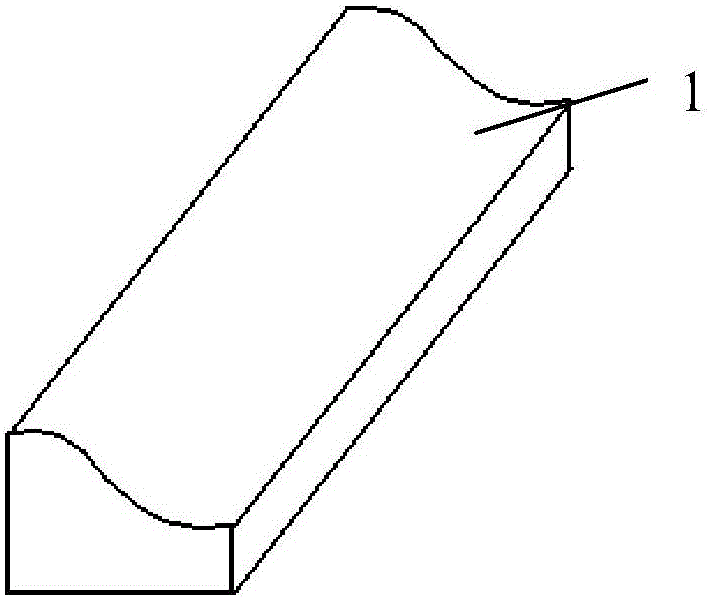

[0040] a. Refer to figure 1 , first make a foam model 1 according to the digital model of the part;

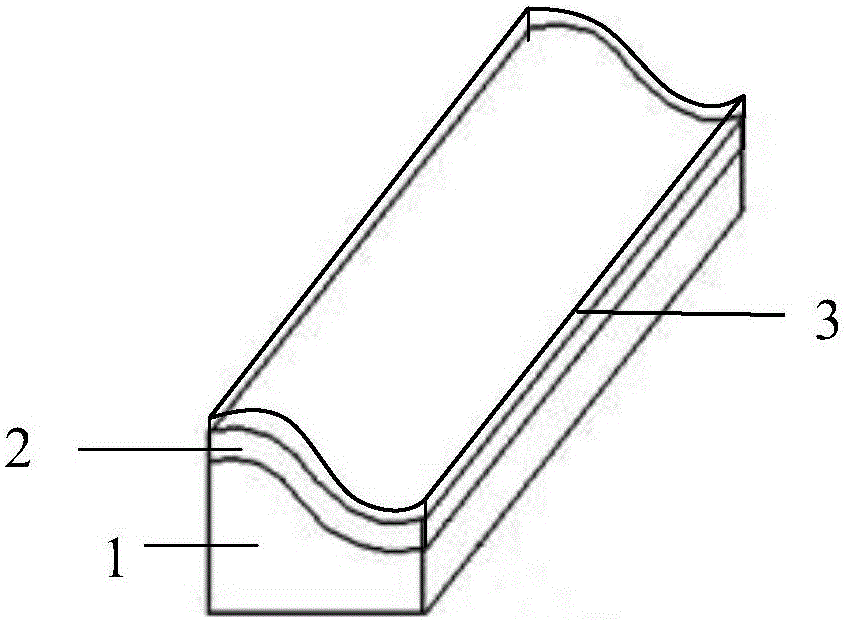

[0041] b. Reference figure 2 , coat about 5mm thick fumed silica material layer 2 and 1mm thick first gel coat resin mixture layer 3 on the surface of the foam model 1 for curing, the fumed silica material layer 2 will play a role after curing Cushioning effect, when the mold enters the high-temperature working state, the thermal deformation of the surface material is affected by the supporting part;

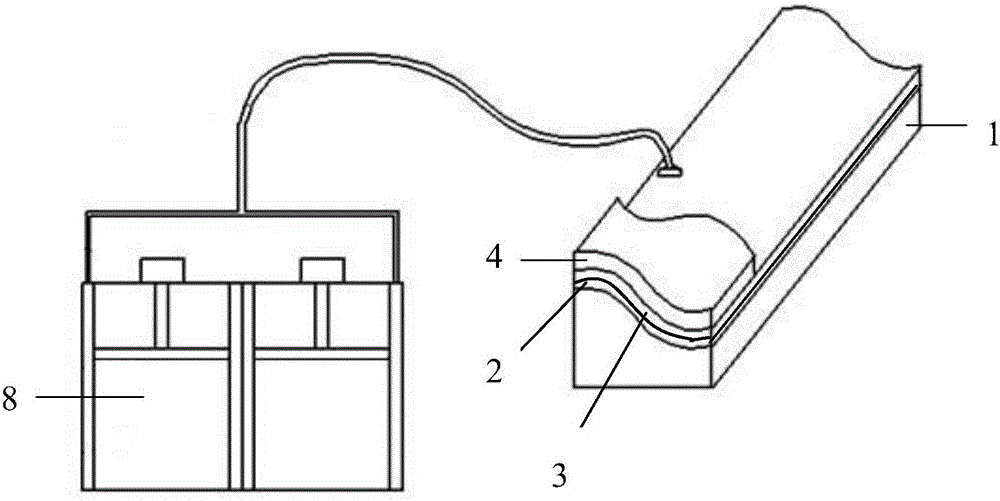

[0042] c. Refer to image 3 After the fumed silica material layer 2 and the first gel coat resin mixture layer 3 of the step b are cured, use a high-viscosity resin mixing extruder 8 to follow the surface of the first gel coat resin mixture layer 3 in the step b 3D coating of the second gel coat resin mixture laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com