Automatic TIG gasket-free single-side welding and double-side molding process for aluminum alloy

A single-sided welding and double-sided forming technology, which is applied in the field of aluminum alloy welding, can solve the problems of low weld pass rate, low efficiency, and easy brittle weld area, and achieve high weld joint coefficient and weld pass rate High, excellent weld quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] An aluminum alloy automatic TIG liner-free single-sided welding and double-sided forming process, comprising the following steps:

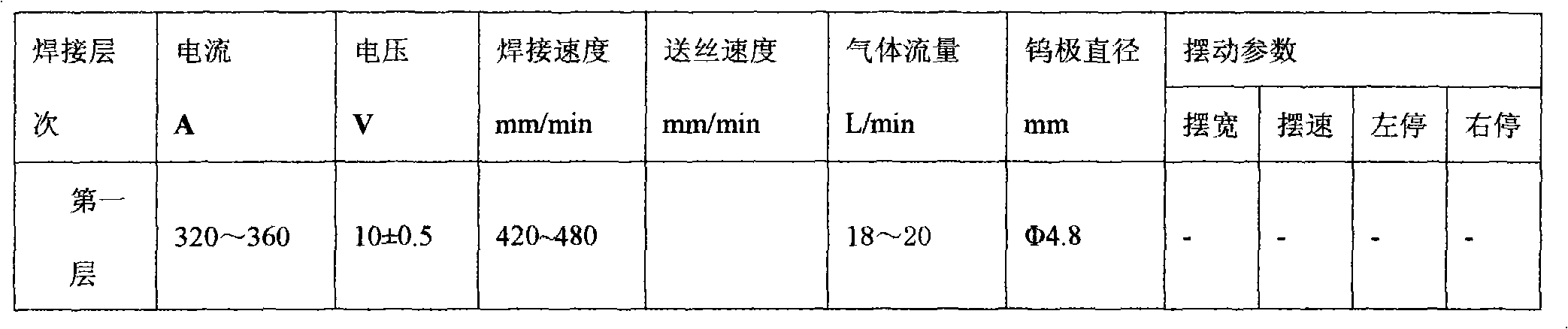

[0020] The first step is to select welding equipment and materials, using an automatic TIG girth welding machine, which can control the welding current, arc voltage, welding speed and wire feeding speed. Argon gas above %, the welding wire adopts ER5356Φ1.6mm welding wire, the cerium tungsten electrode Φ is 4.8mm, and the nozzle diameter of the welding torch is 19mm.

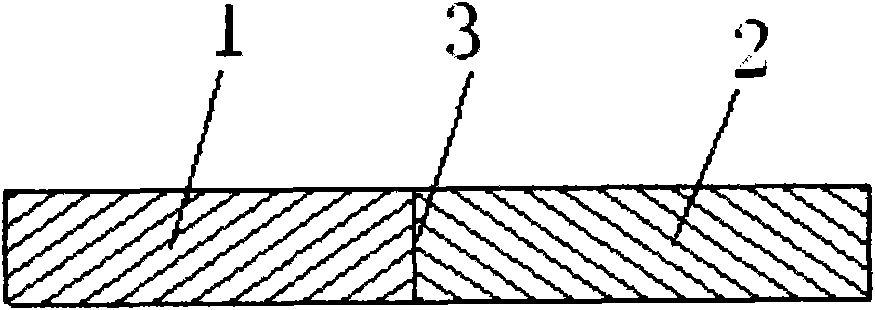

[0021] The second step is assembly and cleaning. Assembly is carried out first, assembly accuracy: misalignment ≤ 0.5mm, gap ≤ 0.5mm, and then tack welding, using MIG semi-automatic unilateral point to fix the block and cylinder, and then use acetone and stainless steel wire The wheel removes the oil and oxide film within 50mm on both sides of the groove, refer to figure 1 , 6 ~ 8mm thick aluminum alloys 1 and 2 use I-shaped groove 3, the groove angle is 50°,

[0022] The t...

Embodiment 2

[0029] An aluminum alloy automatic TIG liner-free single-sided welding and double-sided forming process, comprising the following steps:

[0030] The first step is to select welding equipment and materials, using an automatic TIG girth welding machine, which can control the welding current, arc voltage, welding speed and wire feeding speed. Argon gas above %, the welding wire adopts ER5356Φ1.6mm welding wire, the cerium tungsten electrode Φ is 4.6mm, the nozzle aperture of the welding torch is Φ18mm,

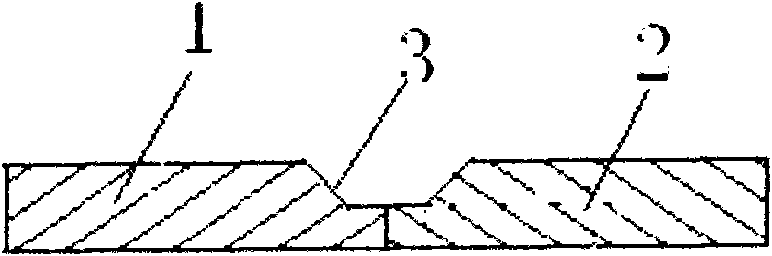

[0031] The second step is assembly and cleaning. Assembly is carried out first, assembly accuracy: misalignment ≤ 0.5mm, gap ≤ 0.5mm, and then tack welding, using MIG semi-automatic unilateral point to fix the block and cylinder, and then use acetone and stainless steel wire The wheel removes the oil and oxide film within 50mm on both sides of the groove, refer to figure 2 10-14mm thick aluminum alloys 1 and 2 use a blunt V-shaped bevel 3 with a bevel angle of 70°.

[0032] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com